SCR system INCA calibration platform based on CCP protocol and development method thereof

A technology of SCR system and protocol, applied in the INCA calibration platform of SCR system based on CCP protocol and its development field, can solve the problems of large calibration workload and short cycle, and achieve the effect of improving calibration efficiency, shortening calibration cycle and standardizing calibration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is further described;

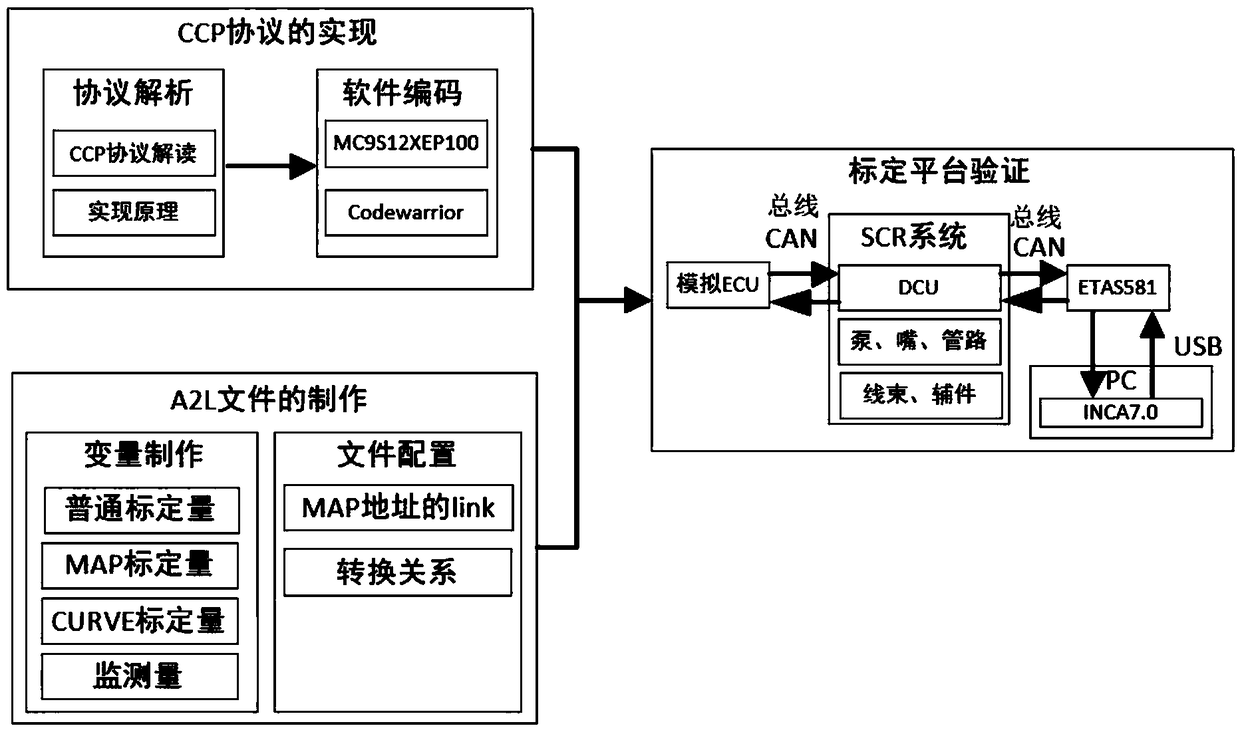

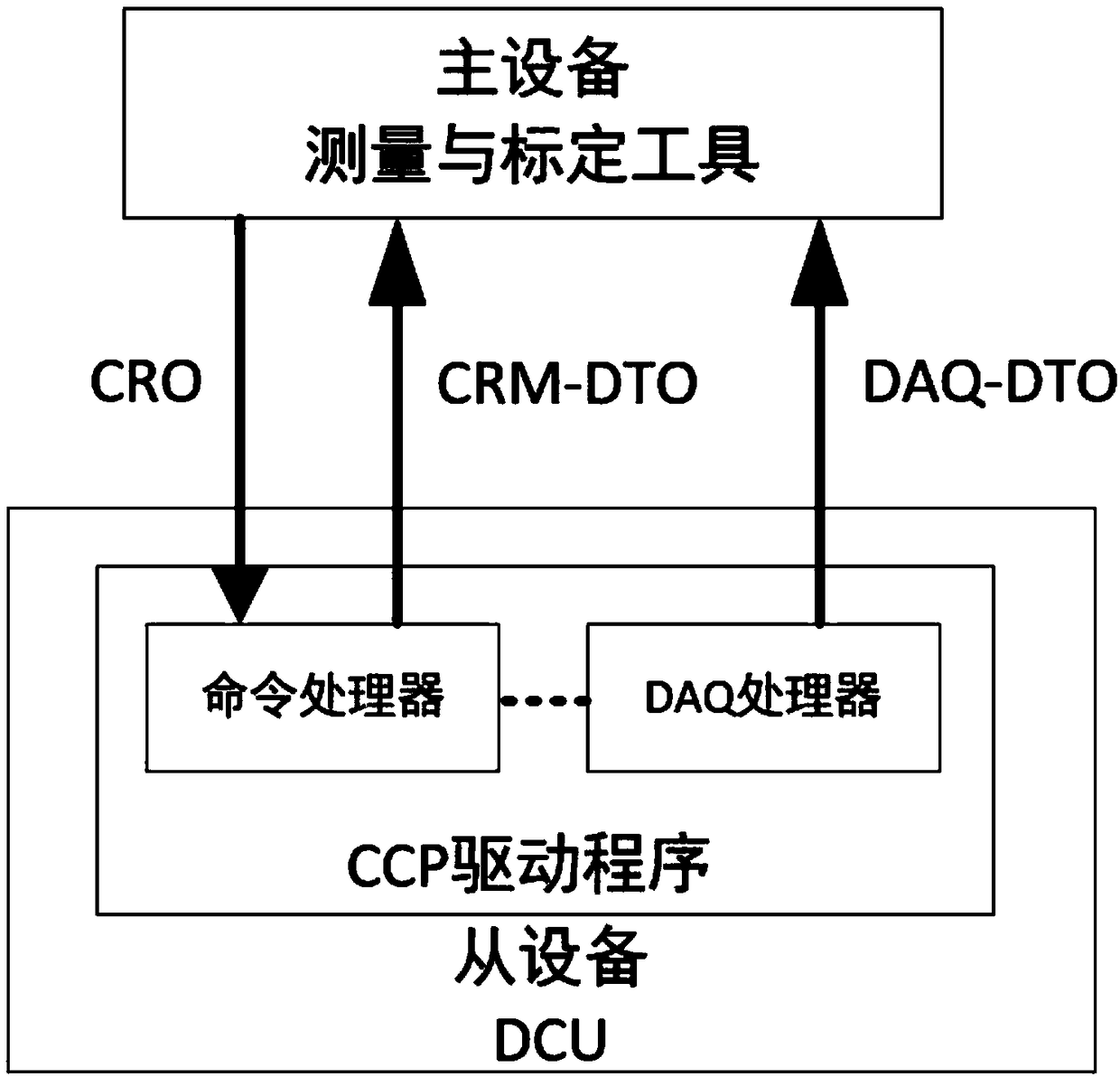

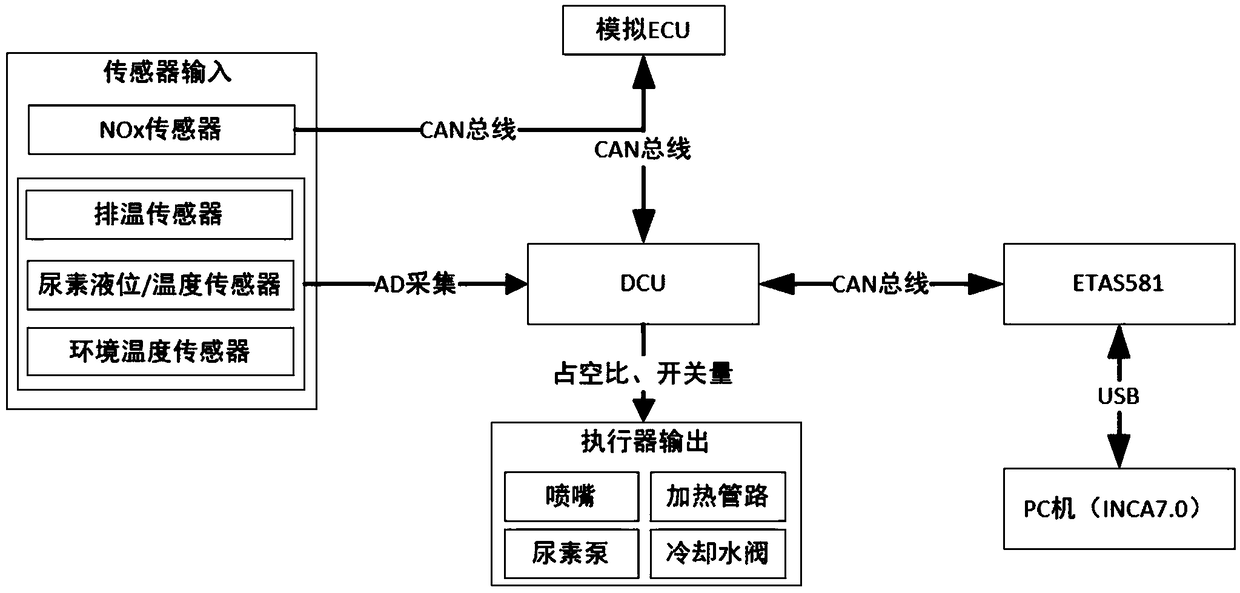

[0016] In the accompanying drawings: a kind of SCR system INCA calibration platform based on the CCP protocol, including the realization of the CCP protocol, the production of the A2L file, and the verification of the calibration platform for verifying the realization of the CCP protocol and the validity of the production of the A2L file; The realization of the CCP protocol includes protocol analysis and software coding; the making of the A2L file includes variable making and file configuration; the verification of the calibration platform includes an analog ECU, an SCR system that communicates with the analog ECU through the CAN bus, and an SCR system that communicates with the analog ECU through the CAN bus. The hardware ETAS581 that communicates with the bus and the SCR system, and the PC-based INCA7.0 software that communicates with the hardware ETAS581 through the CAN bus t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com