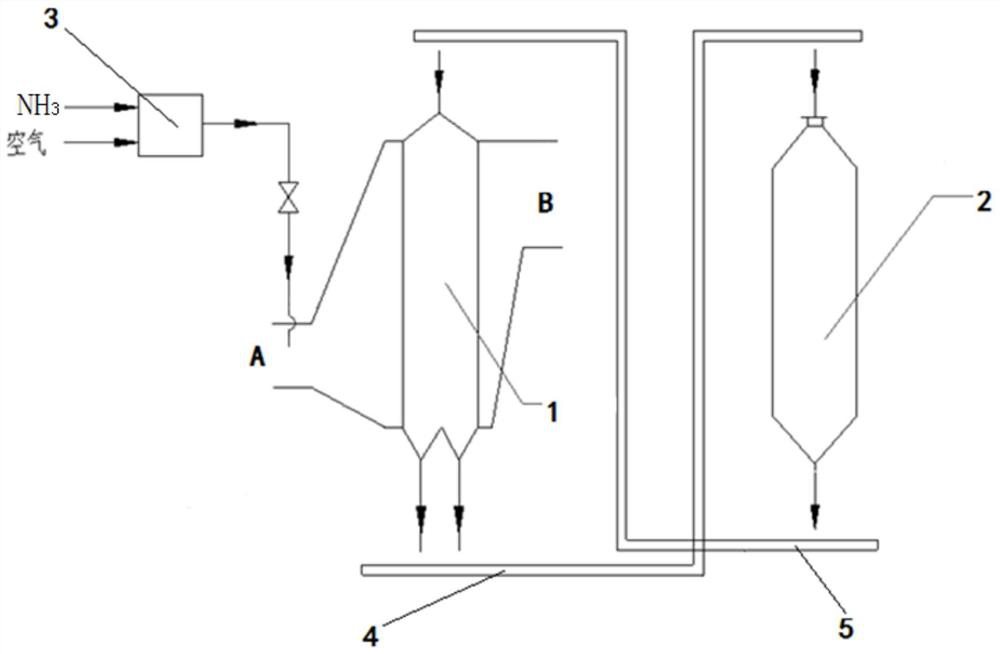

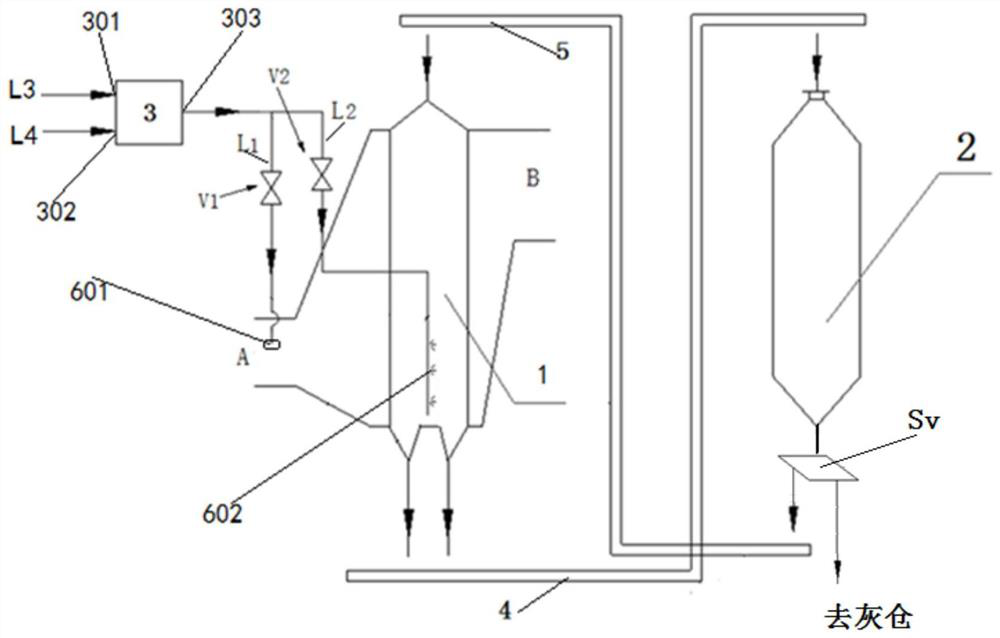

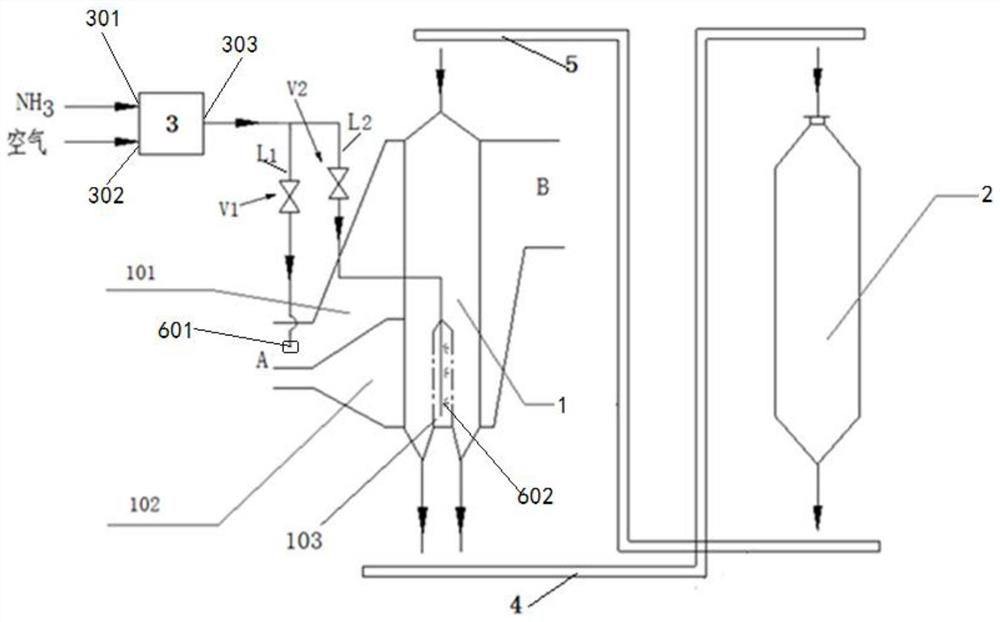

A high-efficiency denitrification ammonia injection system

A denitrification and high-efficiency technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as uncontrollable materials, large quantities, continuous operation loss of processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0103] like Figure 5 As shown in , the size (screen cut-off size) of the finished activated carbon recycled in the desulfurization ammonia injection system is required to be (diameter, D) × 6mm (length, h), then design a kind of sieve to be used in one layer of sieve of vibrating screen 3, wherein the width a and length L of the rectangular sieve hole are: 5mm (width a) × 27mm (Length L). Wherein D is the diameter of the circular cross-section of the activated carbon cylinder to be retained on the screen, and h is the minimum length of the granular activated carbon cylinder to be retained on the screen. a=0.833h.

Embodiment B

[0105] like Figure 5 As shown in , the size (screen cut-off size) of the finished activated carbon recycled in the desulfurization ammonia injection system is required to be (diameter, D) × 4mm (length, h), then design a kind of sieve to be used in one layer of sieve of vibrating screen 3, wherein the width a and length L of the rectangular sieve hole are: 3mm (width a) × 27mm (Length L). where D is the diameter of the circular cross-section of the granular activated carbon cylinder to be retained on the screen. a=0.75h. This mesh size screen is designed to retain medium particle size activated carbon.

Embodiment C

[0107] like Figure 5 As shown in , the size (screen cut-off size) of the finished activated carbon recycled in the desulfurization ammonia injection system is required to be (diameter, D) × 2mm (average length), then design a kind of screen cloth to be used in the layer screen cloth of vibrating screen 3, wherein the width a and the length L of rectangular screen hole are: 1.6mm (width a) × 16mm (Length L). where D is the diameter of the circular cross-section of the granular activated carbon cylinder to be retained on the screen. a=0.75h.

[0108] The adsorption tower generally has at least 2 activated carbon chambers.

[0109] Preferably, there is a circular roller feeder or discharge circular roller G at the bottom of each activated carbon chamber AC-c of the adsorption tower. Generally, the adsorption tower has at least two activated carbon chambers AC-c.

[0110] For the roller feeder or the discharge roller G described here, the roller feeder or the discharge roll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap