Electromagnetic side pressing drawing test device and method

A test device, test method technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

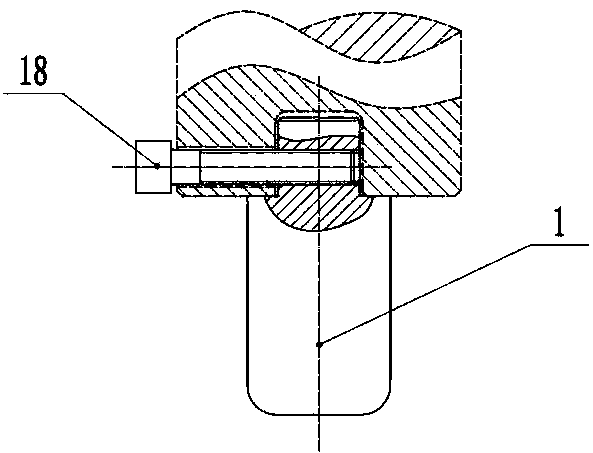

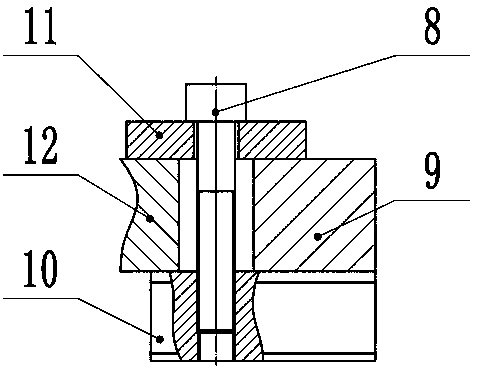

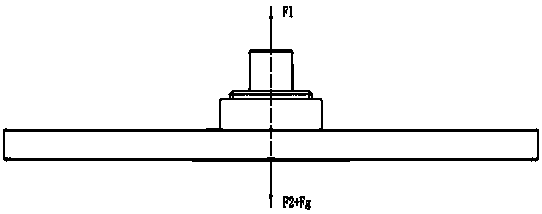

[0037] figure 1 It is a sectional view of the electromagnetic blank-holding deep-drawing device of the present invention, and the electromagnetic blank-holding deep-drawing device comprises a punch 1, a blank-holding ring 2, a magnetic force ring 3, an excitation coil 4, a fixed ring 5, a die 6, and a cylindrical head Hexagon screw 7, cylinder head hexagon socket screw 8, spacer 9, fixed block 10, pressure plate 11, bottom plate 12, spacer 13, cylinder head hexagon socket head screw 14, cylinder helical compression spring 15, pusher plate 16, inside cylinder head Hexagonal screw 17, hexagon socket head cap screw 18; Described elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com