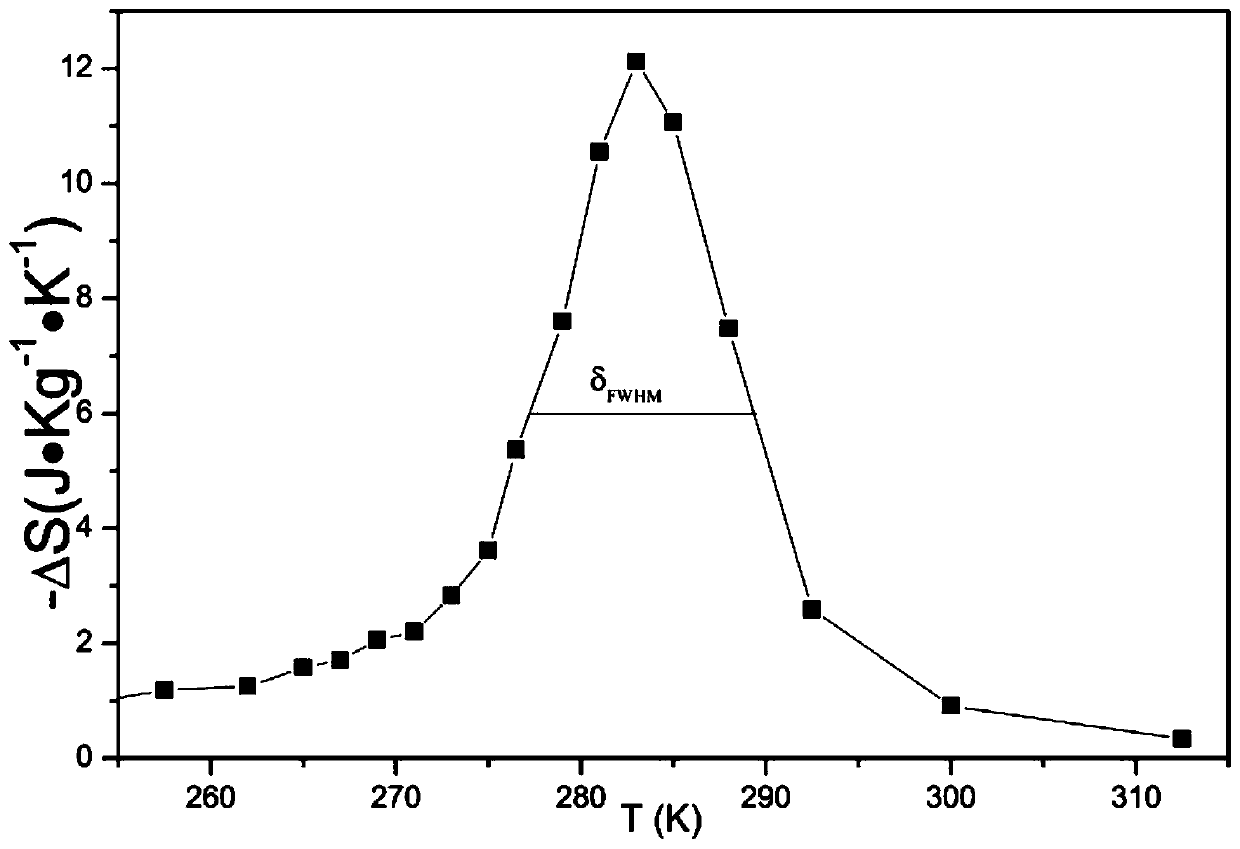

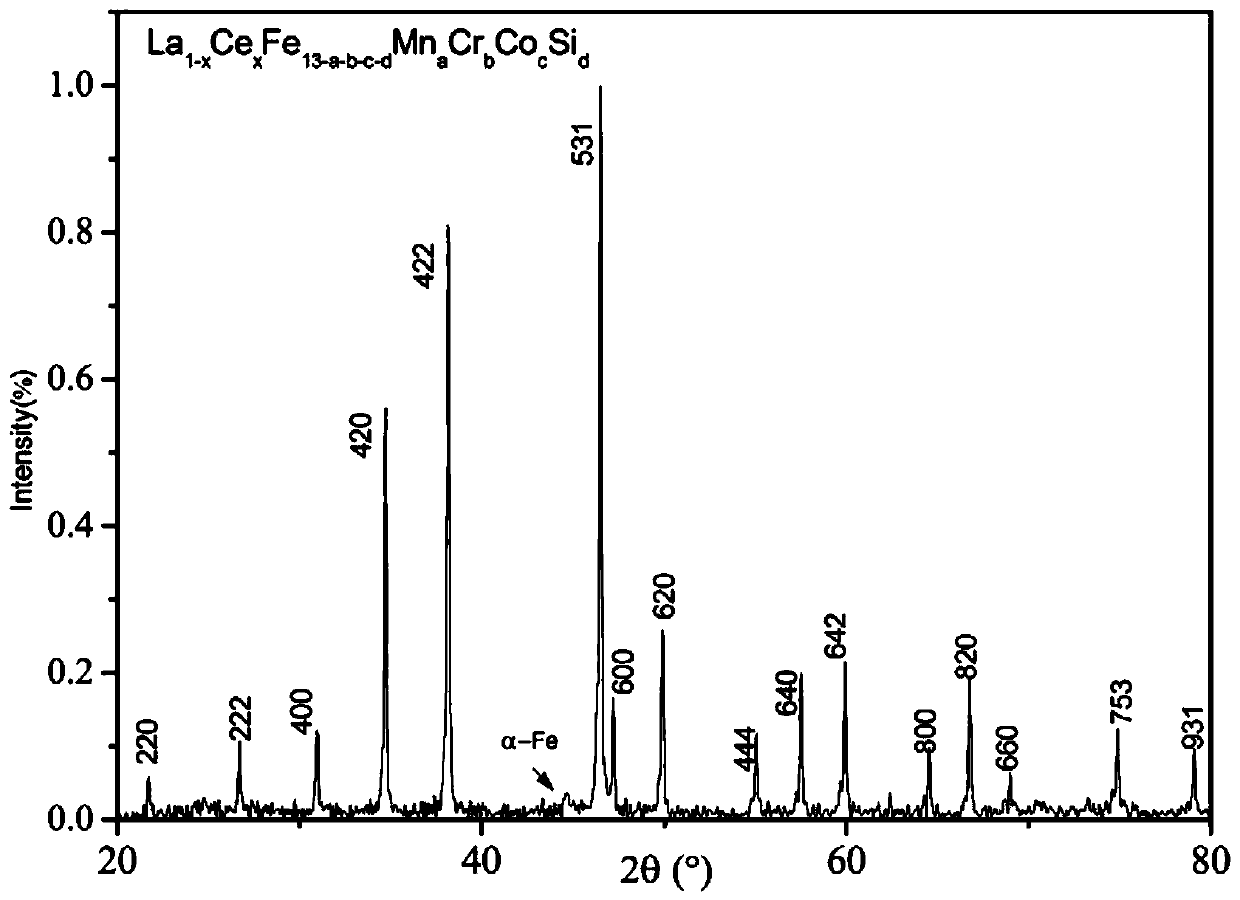

A method for improving the half-height width of magnetic entropy curve of lafesi alloy magnetic refrigeration material

A magnetic refrigeration material and magnetic entropy change technology, which is applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of magnetic entropy change, low half-height width, lower yield, and easy water ingress. Achieve wide half-width of magnetic entropy curve and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

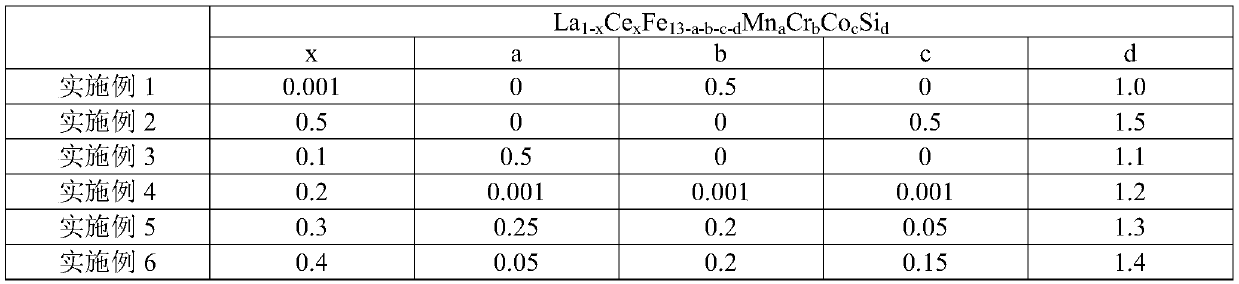

Embodiment 1

[0025] 1. a method for improving the FWHM of the magnetic entropy curve of LaFeSi alloy magnetic refrigeration material, is characterized in that comprising the following steps:

[0026] a) Heat treatment: subject the LaFeSi alloy magnetic refrigeration material to high-temperature heat treatment at 1000-1300° C., and the heat treatment time is 1-24 hours;

[0027] b) Furnace cooling: turn off the heating after the heat treatment, and cool in the furnace for 0 to 60 minutes;

[0028] c) Air cooling: take out the heating body in the furnace after the furnace cooling is completed, and use a fan or blower to carry out air cooling treatment on the furnace body and the LaFeSi alloy magnetic refrigeration material in the furnace body, so that it is cooled to room temperature within 10 to 300 minutes;

[0029] d) Hydrogen charging: crush the cooled LaFeSi alloy magnetic refrigeration material until the particle size is less than 1 mm, and perform hydrogen charging treatment in a hydr...

Embodiment 2

[0031] 1. a method for improving the FWHM of the magnetic entropy curve of LaFeSi alloy magnetic refrigeration material, is characterized in that comprising the following steps:

[0032] a) Heat treatment: subject the LaFeSi alloy magnetic refrigeration material to high-temperature heat treatment at 1000-1300° C., and the heat treatment time is 1-24 hours;

[0033] b) Furnace cooling: turn off the heating after the heat treatment, and cool in the furnace for 0 to 60 minutes;

[0034] c) Air cooling: take out the heating body in the furnace after the furnace cooling is completed, and use a fan or blower to carry out air cooling treatment on the furnace body and the LaFeSi alloy magnetic refrigeration material in the furnace body, so that it is cooled to room temperature within 10 to 300 minutes;

[0035] d) Hydrogen charging: crush the cooled LaFeSi alloy magnetic refrigeration material until the particle size is less than 1 mm, and perform hydrogen charging treatment in a hydr...

Embodiment 3

[0037] 1. a method for improving the FWHM of the magnetic entropy curve of LaFeSi alloy magnetic refrigeration material, is characterized in that comprising the following steps:

[0038] a) Heat treatment: subject the LaFeSi alloy magnetic refrigeration material to high-temperature heat treatment at 1000-1300° C., and the heat treatment time is 1-24 hours;

[0039] b) Furnace cooling: turn off the heating after the heat treatment, and cool in the furnace for 0 to 60 minutes;

[0040] c) Air cooling: take out the heating body in the furnace after the furnace cooling is completed, and use a fan or blower to carry out air cooling treatment on the furnace body and the LaFeSi alloy magnetic refrigeration material in the furnace body, so that it is cooled to room temperature within 10 to 300 minutes;

[0041] d) Hydrogen charging: crush the cooled LaFeSi alloy magnetic refrigeration material until the particle size is less than 1 mm, and perform hydrogen charging treatment in a hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com