Flexible flushing protective structure for marine engineering infrastructure

A technology for infrastructure and marine engineering, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of difficulty in ensuring the uniformity of the protection area, damage to sandbags, and time-consuming, so as to improve the efficiency of offshore construction and the effect of scour protection. , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

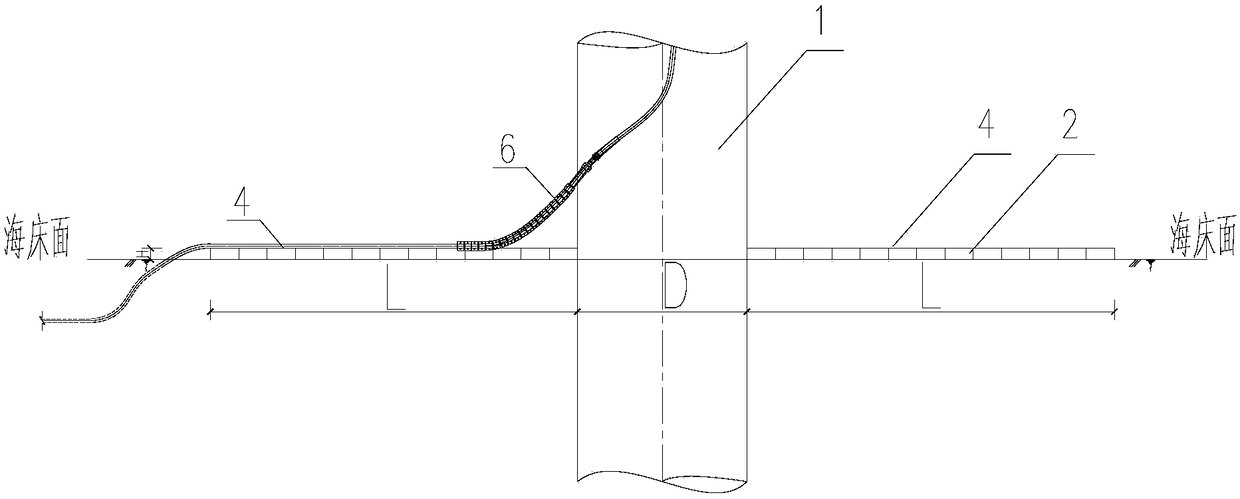

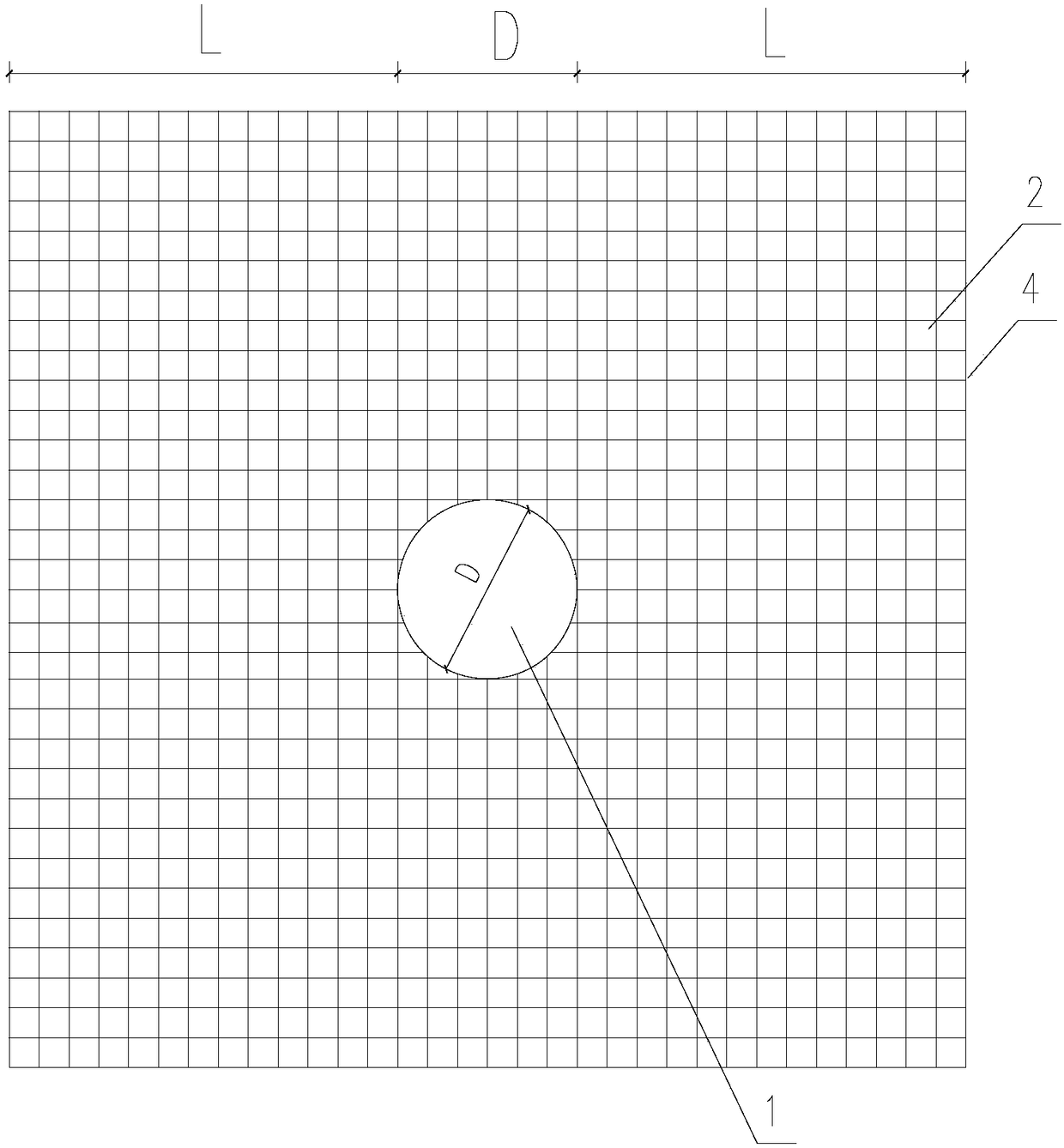

[0020] Such as figure 1 , figure 2 As shown, this embodiment is an application example of a large-diameter single pile foundation, including a large-diameter single pile 1 and a flexible erosion protection structure of the large-diameter single pile 1 .

[0021] The flexible scour protection structure includes a flexible scour protection surface 4 . A plurality of protection units 2 are connected by connecting cables 3 to form a flexible scour protection surface 4 .

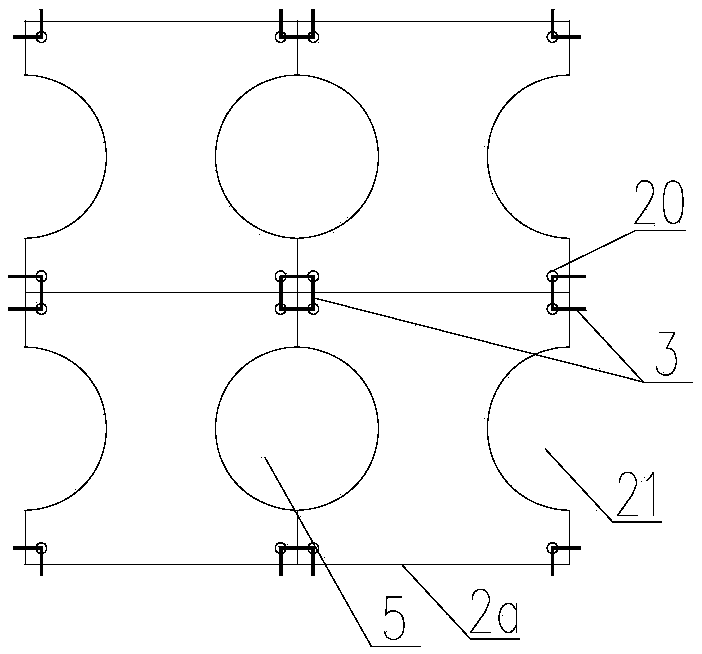

[0022] The protective unit 2 is made of prefabricated concrete blocks or waste tires or other materials. The protective monomer can have multiple implementations, such as Figure 3-1 , 3-2 , 3-3, the protection unit 2a can have a groove 21 on the outside and after a plurality of protection units 2a are connected by the connecting cable 3, the groove forms a cavity 5 through the flexible scouring protection surface. The side wall of the cavity is also concave 51 on the groove wall, preferably, the entire gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com