Pixel circuit, drive method thereof and display panel

A technology of a pixel circuit and a driving method, which is applied in the field of organic light-emitting display, achieves the effect of solving the requirements of thickness and bending, reducing the difficulty of manufacturing process, and eliminating the need for a touch panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

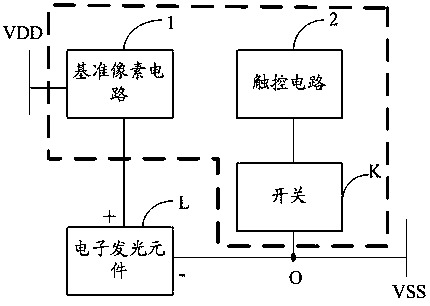

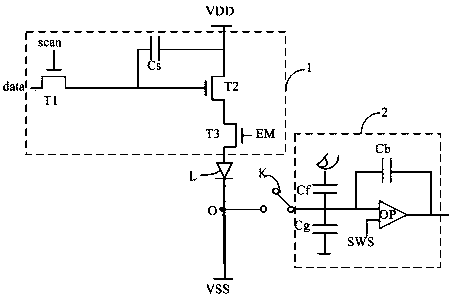

[0040] like figure 2 Shown is a pixel circuit provided in Embodiment 1 of the present invention, including a reference pixel circuit 1, a touch circuit 2, and a switch K; wherein,

[0041] One end of the reference pixel circuit 1 is connected to the DC high-voltage signal VDD, and the other end is connected to the positive electrode (+) of an electronic light-emitting element L and then connected to the DC low-voltage signal VSS through the negative electrode (-) of the electronic light-emitting element L to drive or cut off the electron. The light emitting element L emits light;

[0042] The touch circuit 2 is connected to a connection O between the negative pole (-) of the electroluminescent element L and the DC low-voltage signal VSS through the switch K, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com