Photocathode and its preparation method

A technology of photocathode and metal nanoparticles, which is applied in the manufacture of light-emitting cathodes, photoemission cathodes, and main electrodes of discharge tubes. The effect of strong absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

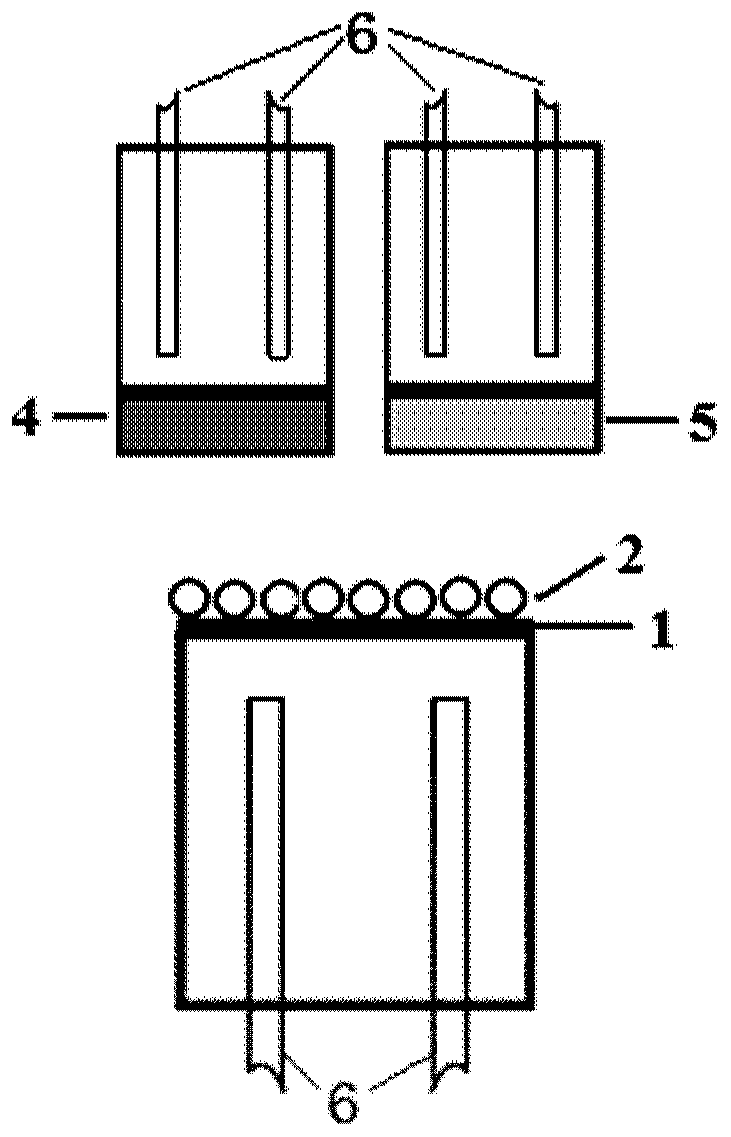

[0038] The preparation materials of the alkali metal source 5 include: cesium, sodium or potassium.

[0039] The heating body 6 is used for heating, and the material includes: tungsten, molybdenum or tungsten-rhenium and the like.

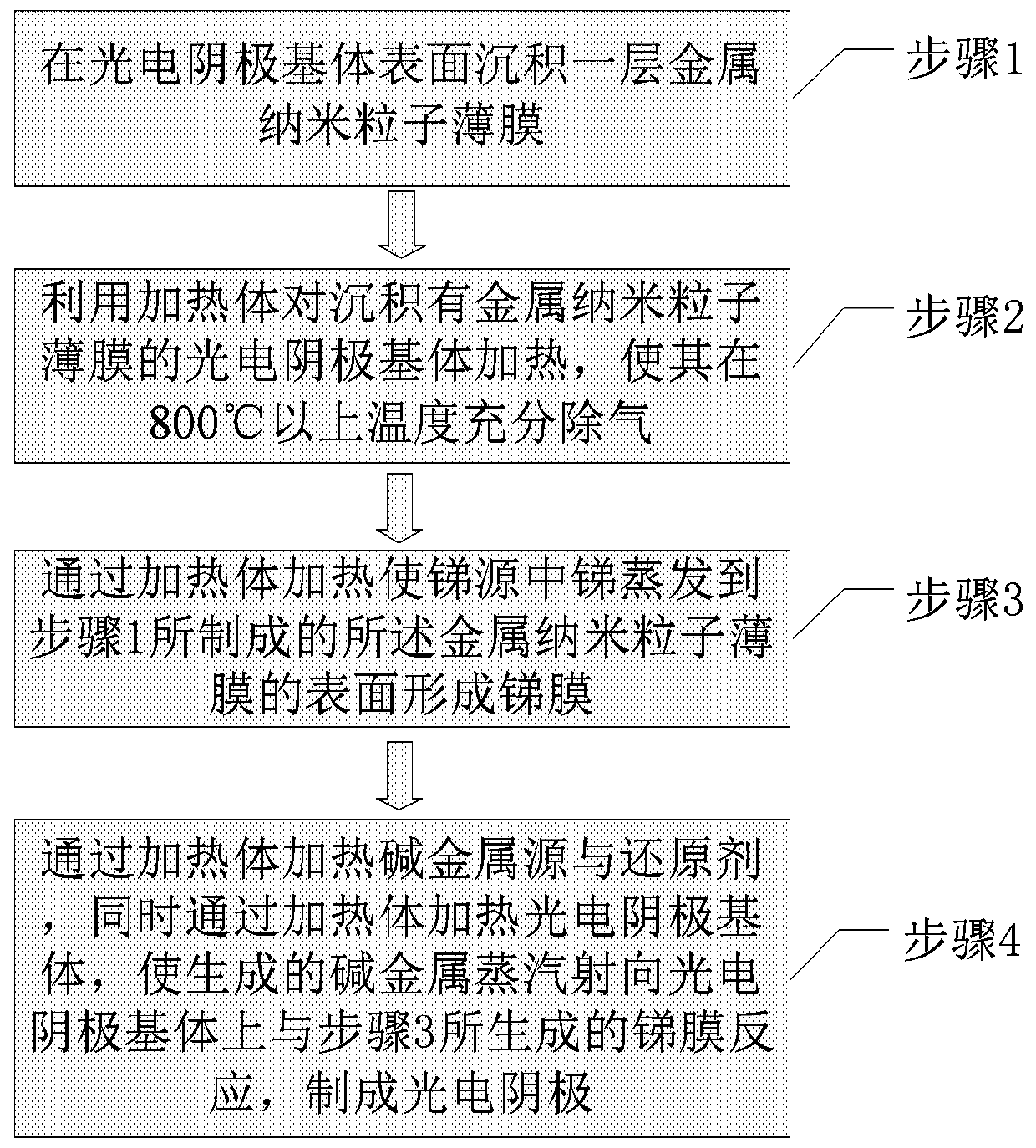

[0040] In an embodiment of the present disclosure, a method for preparing a photocathode is also provided, image 3 It is a schematic flow chart of the preparation method of the photocathode in the embodiment of the present disclosure, combined with figure 2 and image 3 Shown, described preparation method comprises:

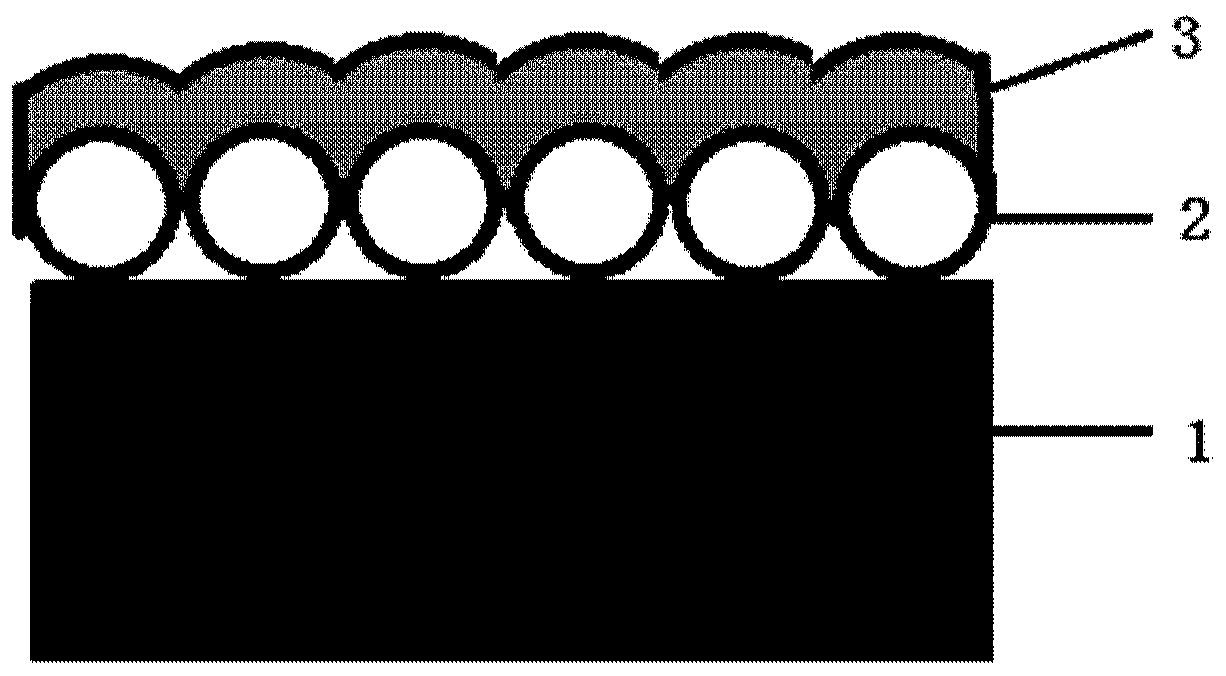

[0041] Step 1: Deposit a layer of metal nanoparticle film 2 on the surface of the photocathode substrate 1;

[0042] The thickness of the metal particle film is 200nm-500nm, and the diameter of the metal nano-particle is about 10nm-100nm;

[0043] Step 2: using the heating body 6 to heat the photocathode substrate 1 deposited with the metal nanoparticle thin film 2, so that it is fully degassed at a temperature above 800°C;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com