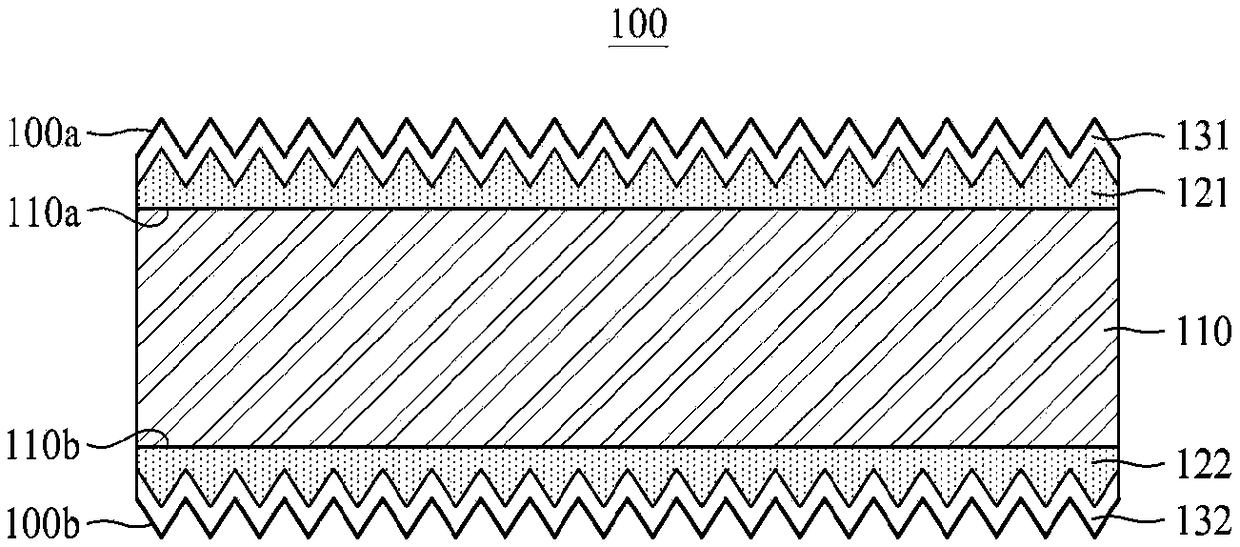

Copper foil, method for manufacturing same, electrode comprising same, and secondary battery comprising same

A secondary battery, manufacturing method technology, applied in the direction of electrode carrier/current collector, non-aqueous electrolyte storage battery, lithium storage battery, etc., can solve the problems of short life, waste of resources, inconvenience to consumers, etc., to minimize inconvenience and waste of resources minimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

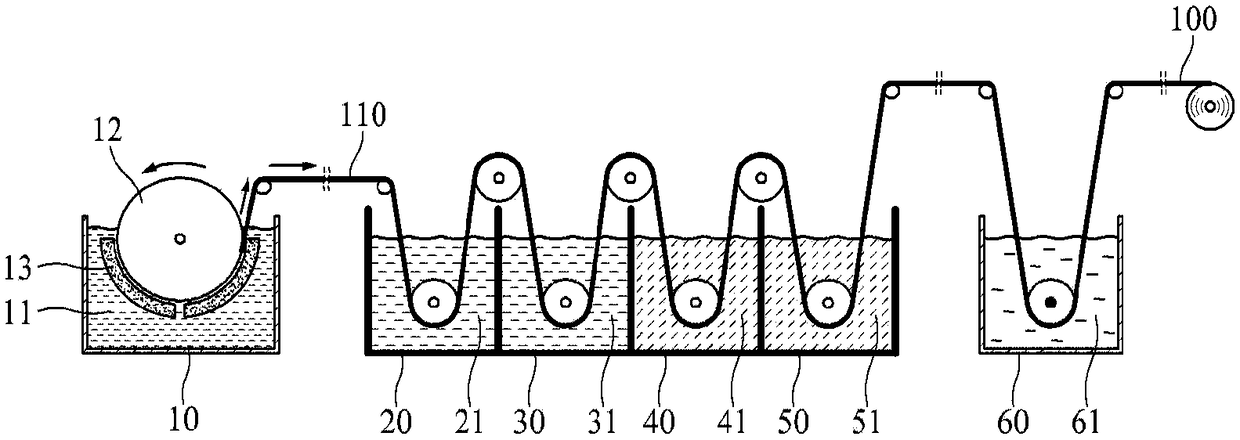

[0082] at 50A / dm 2 A current density of 10 mm was applied to the anode plate and the rotating cathode drum arranged at a distance of 10 mm in the electrolyte solution of the electrolytic cell, whereby a copper film was electrodeposited on the rotating cathode drum. For electroplating as described above, the copper wire heat-treated at 700°C was acid-washed with sulfuric acid, put into the electrolytic solution, and the rotating cathode The surface of the drum is ground.

[0083] In the step of forming the copper film, the electrolytic solution was maintained at 50° C. and continuous filtration of the electrolytic solution was performed, and the flow rate of the electrolytic solution supplied to the electrolytic cell was 40 m 3 / hour, and the flow deviation is adjusted within 1%. In the electrolyte, the copper concentration is maintained at 70±10g / L, the sulfuric acid concentration is maintained at 80±10g / L, the concentration of thiourea as an organic sulfide additive is main...

Embodiment 2

[0087] In addition to the total current i applied via the nucleation-generating plating bath c_total and the total current i applied via the nuclei growth plating bath t_total Copper foil was manufactured in the same manner as in Example 1 except that the ratio was 0.31.

Embodiment 3

[0089] In addition to the total current i applied via the nucleation plating bath c_total and the total current i applied through the nuclei growth plating bath t_total Copper foil was produced in the same manner as in Example 1 except that the ratio was 1.97.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com