Straw crusher

A technology of straw grinder and crushing roller, which is applied in agricultural machinery and tools, cutting equipment, application, etc. It can solve the problems affecting application and uneven texture of straw debris, and achieve improved crushing quality, improved crushing effect, and uniform texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

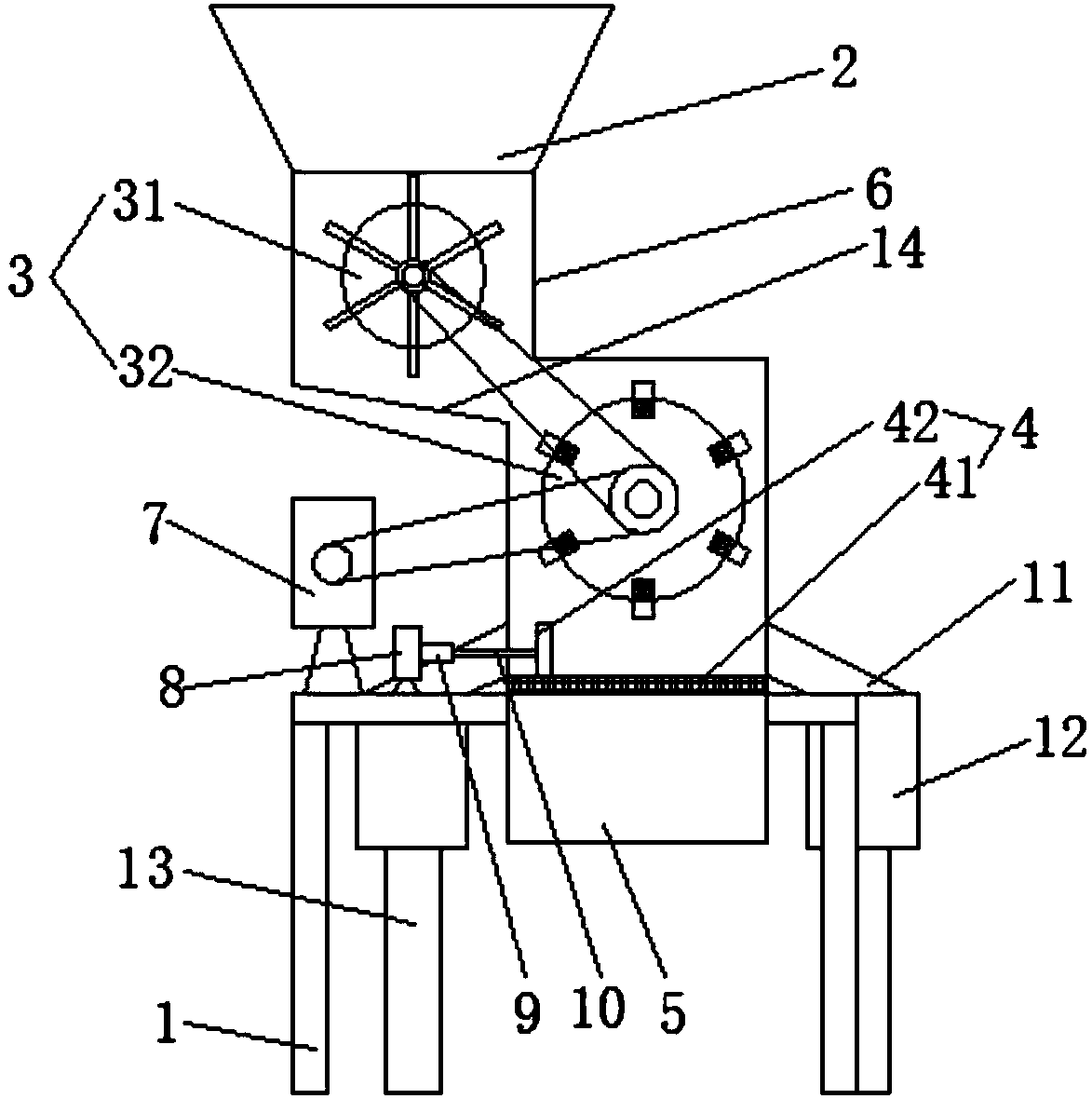

[0017] As shown in the accompanying drawings, a straw pulverizer includes a frame 1, a feeding port 2, a pulverizing structure 3, a screening structure 4 and a discharging port 5; an open square bin 6 is fixed on the frame 1, so the The feeding port 2 is fixed on the top of the open square bin 6 by screws, and the crushing structure 3 is located in the open square bin 6, including a shearing roller 31 and a crushing roller 32 that are staggered up and down. 4. It includes a hole screen 41 and a sweeping plate 42 suspended above the hole screen 41. The frame 1 is located on one side of the open square bin 6 and is fixed with a first motor 7 and a second motor 8. A motor 7 is connected to the crushing roller 32 through a conveyor belt, the output shaft of the second motor 8 is connected to the disc cam 9 through a gear, and the end face of the disc cam 9 is pressed against one end of the driven rod 10, and the driven rod The other end of 10 is hinged on the central position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com