A material mixing device with multiple mixing chambers

A material mixing and mixing cavity technology, applied in mixers, grain processing, food science and other directions, can solve the problems of uniform mixing of difficult powder materials, affecting mixing effect, low production efficiency, etc., to avoid material agglomeration and facilitate material mixing. , Improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

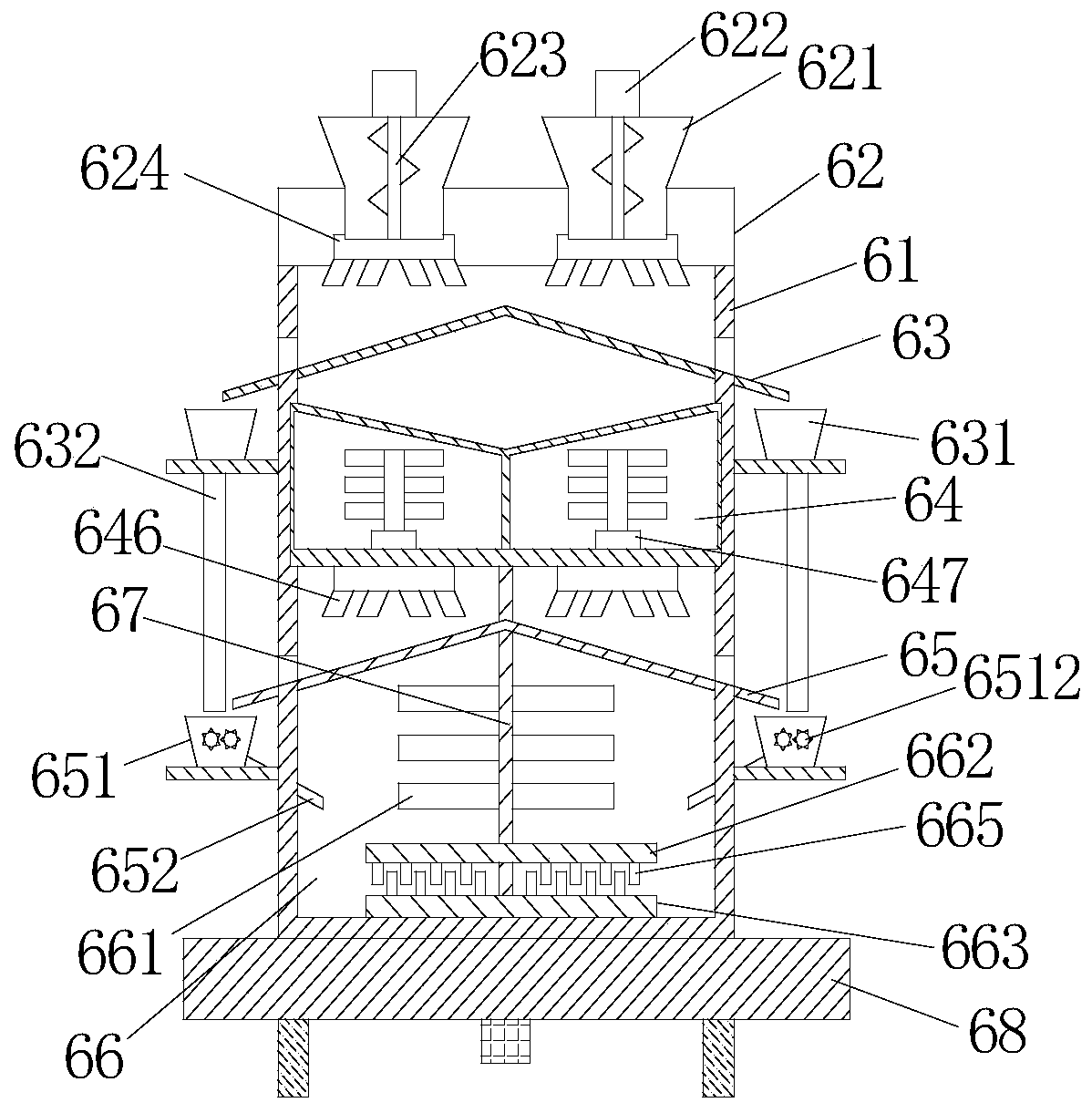

[0026] Such as figure 1As shown, the present embodiment discloses a material mixing device with multiple mixing chambers, including a mixing tank body 61 and a mixing upper cover 62 covered on the mixing tank body 61 , and in the cavity of the mixing tank body 61 A first mixing sieve plate 63, a first mixing chamber 64, a second mixing sieve plate 65, and a crushing / mixing integrated chamber 66 are arranged sequentially from top to bottom. The upper part passes through the crushing / mixing integrated chamber 66 , the second mixing sieve plate 65 and extends into the mixing shaft 67 of the first mixing chamber 64 . Two feeding bins 621 are installed on the mixing upper cover 62, and a feeding motor 622 is installed on the feeding bin 621, and a screw feeding rod 623 is installed in the feeding bin 621, and the feeding motor 622 is connected with the screw feeding rod 623 , the bottom of the feeding chamber 621 is installed with a first spraying device 624 . Such as Figure 4 ...

Embodiment 2

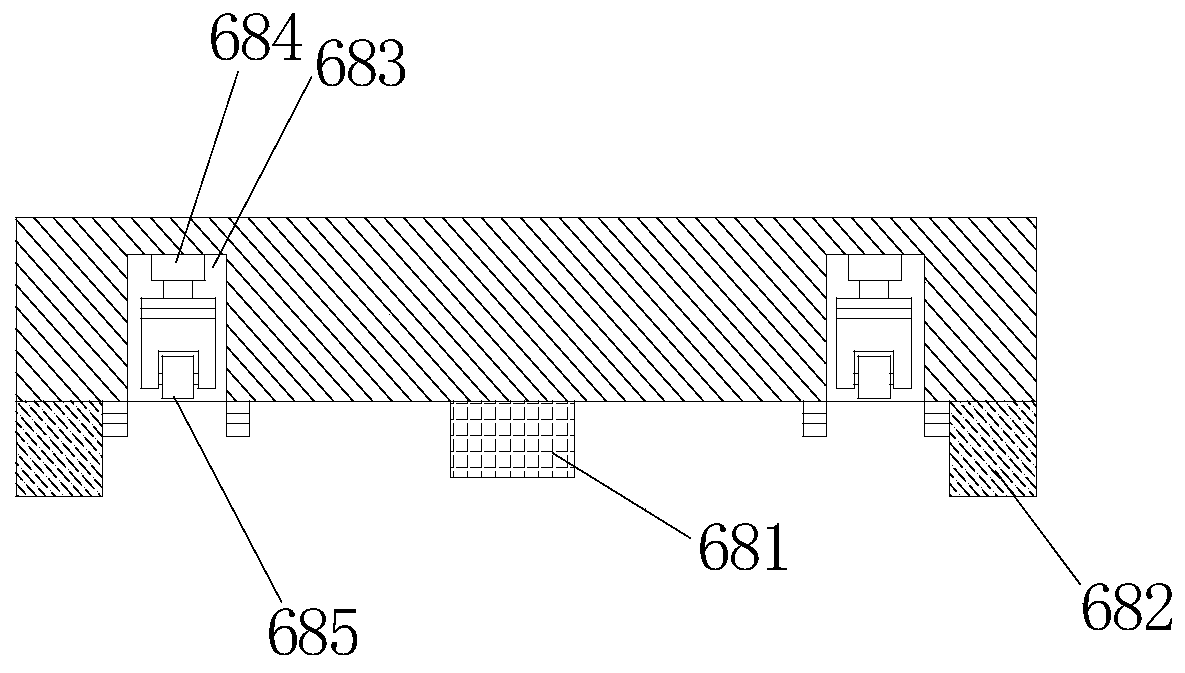

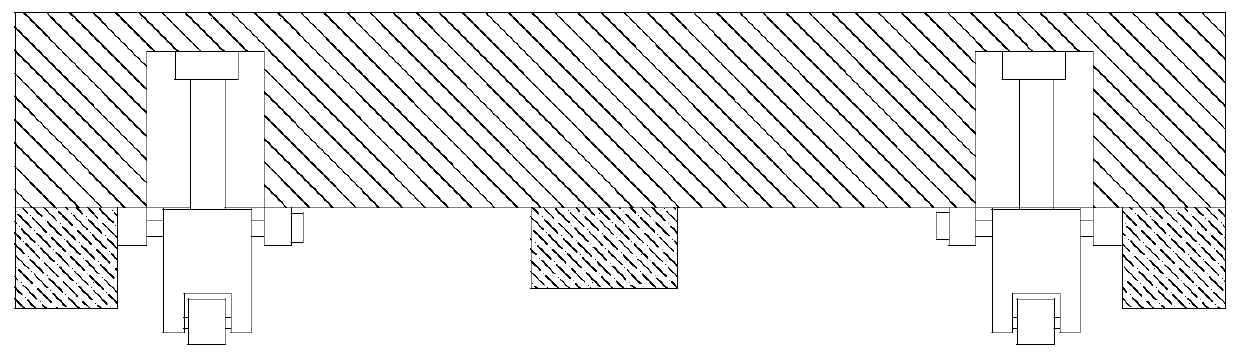

[0030] Such as Figure 1-3 As shown, the difference between this embodiment and the above-mentioned embodiments is that the mixing device also includes a base 68 on which a rotating motor 681 is installed, the rotating motor 681 is connected to the mixing shaft 67, and several supporting legs 682 are installed on the base 68. Around the base 68 are also provided with some receiving grooves 683, in which a lifting cylinder 684 vertically arranged is installed, the upper end of the lifting cylinder 684 is fixedly connected with the base 68, and the lower end of the lifting cylinder 684 is equipped with a universal wheel 685.

[0031] Traditional material mixing devices generally have a fixed base, which makes it cumbersome and time-consuming to move the entire device. There is also a part of the material mixing device to install moving wheels on the lower part of the base for the convenience of moving, but it vibrates greatly when it moves, and its stability is not enough. In t...

Embodiment 3

[0033] Such as figure 1 , 6 As shown, the difference between this embodiment and the above-mentioned embodiments is that the first crushing device 651 includes a crushing chamber 6511, and two crushing rollers 6512 that cooperate with each other are installed in the crushing chamber 6511, and crushing shafts are installed on the two crushing rollers 6512. 6513, wherein a crushing motor 6514 is installed on one of the crushing shafts 6513, and transmission teeth 6515 are installed on the two crushing shafts 6513, and are connected by transmission teeth 6515 between the two crushing shafts 6513.

[0034] Because two crushing rollers 6512 that cooperate with each other are installed in the crushing chamber 6511, the crushing effect is good. Since the crushing shafts 6513 are installed on the two crushing rollers, and the two crushing shafts 6513 are connected by transmission gears 6515, and a crushing motor 6514 Just can drive two crushing rollers 6512 to move, save the use cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com