Ultrasonic electrolysis device for economically and efficiently oxidizing industrial wastewater

A technology of industrial wastewater and electrolysis device, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of unsatisfactory treatment effect of high-concentration refractory organic wastewater, high investment and operating costs, Occupying a large area and other problems, achieving the effect of small investment, low operating cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

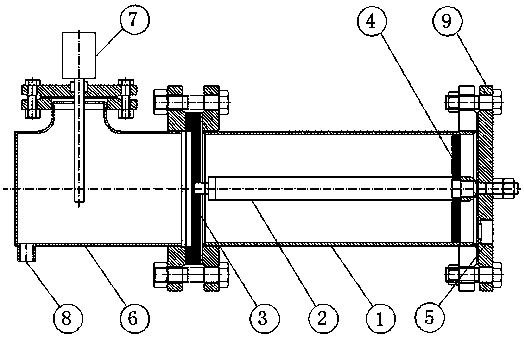

[0007] The ultrasonic electrolysis device of the economical and efficient oxidation industrial waste water of the present invention is as figure 1 As shown: there are ultrasonic chambers 6 connected side by side by flanges and a cylindrical electrolytic cell 1 with micro-electrolytic fillers inside. There is a waste water inlet 8 below the ultrasonic chamber 6 and an ultrasonic vibrator 7 above. The ultrasonic chamber 6 and the electrolytic cell 1 An anode support 3 is provided at the junction, and connected to the anode support 3 is the anode 2 located at the axis of the electrolytic cell 1 (the titanium anode is the central axis, the grid rod structure is made of titanium Ti plated with SbO2), and the cylinder of the electrolytic cell 1 It is a cathode, and the other end of the anode 2 is connected to the flange 9 arranged at the end of the electrolytic cell 1 and has a radially arranged water outlet filter 4 , and a waste water outlet 5 is arranged on the flange 9 .

[0008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com