Preparation method of visible light curing self-repairing fluorine-containing polyurethane resin

A polyurethane resin and self-repairing technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of carboxylic acid halides, and can solve problems such as poor low temperature resistance and high brittleness of polyurethane resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

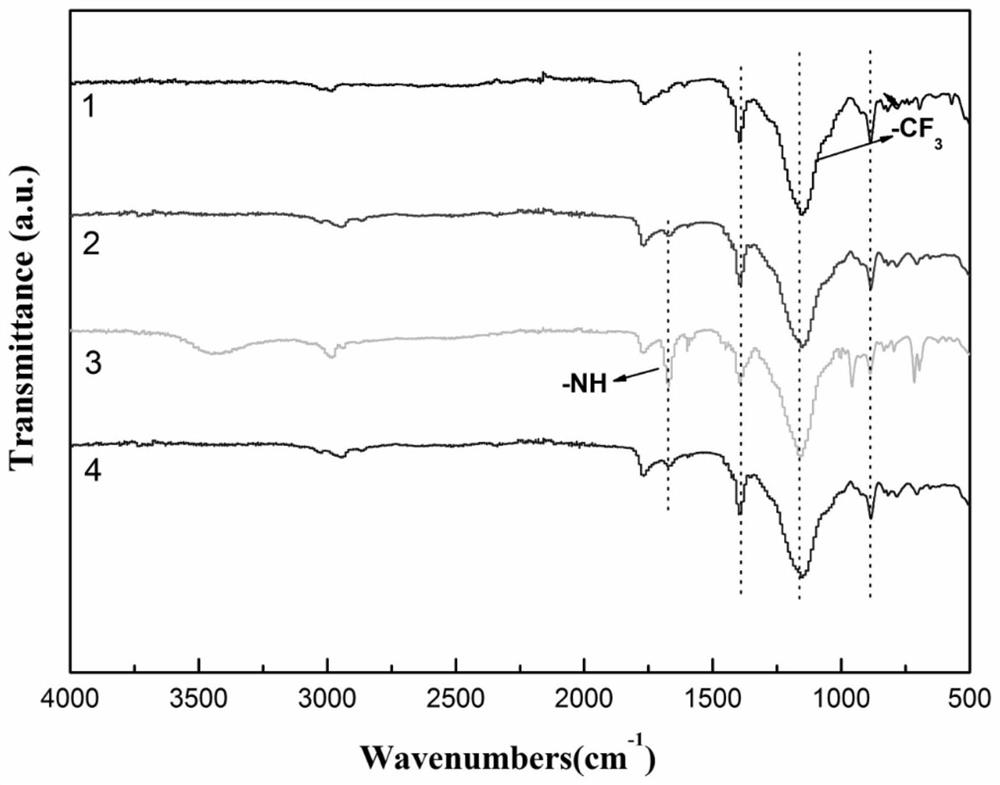

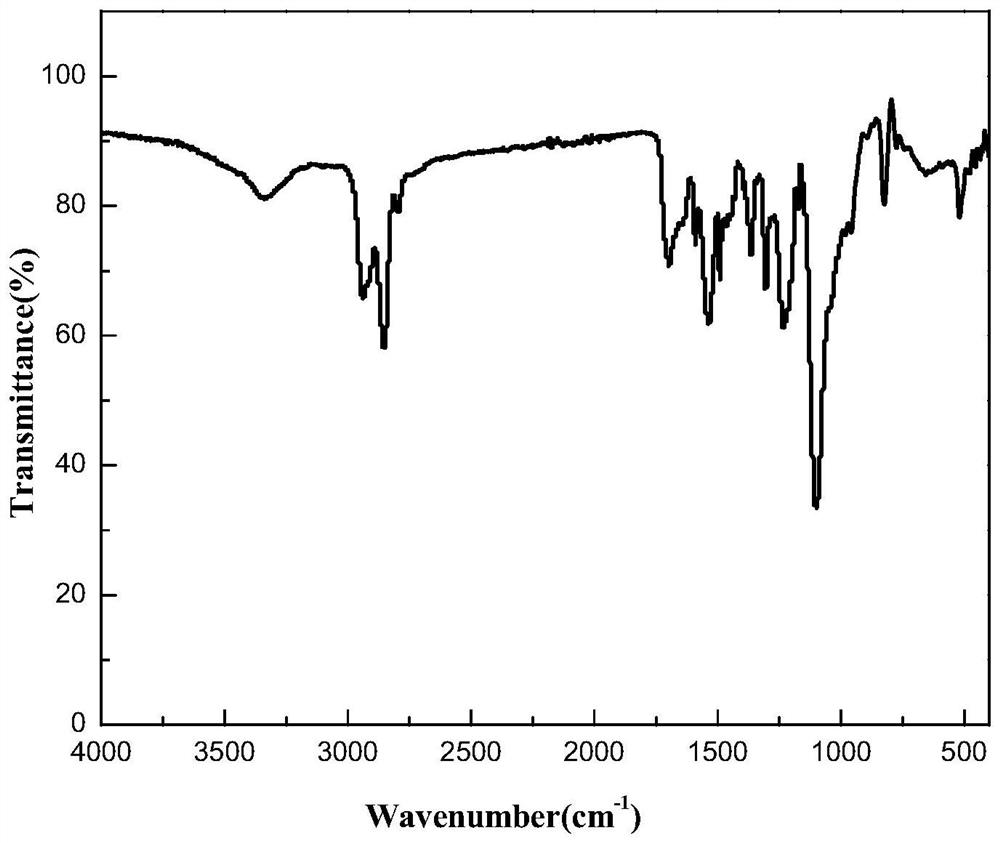

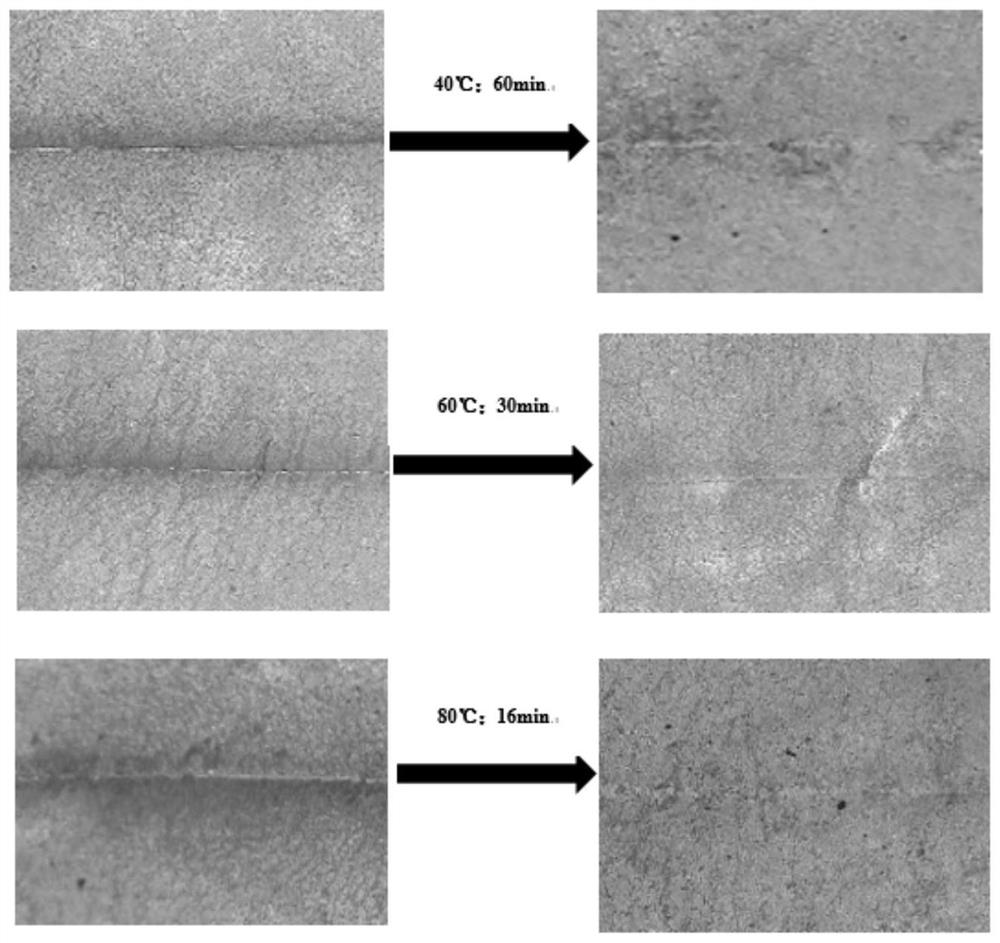

[0045] Add 20 mL of dichloromethane into a three-necked flask equipped with nitrogen protection and a magnetic stirring device, and 0.01 mol of 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl -1-acetone] and 0.01mol triethylamine were dissolved in dichloromethane, and magnetically stirred at room temperature to make them mix uniformly. After reacting for 2 hours, the temperature was rapidly lowered, and 15 mL of dichloroethane and 0.02 mol of trifluoroacetyl chloride were slowly added to the reaction vessel in an ice-water bath, and the reaction temperature was controlled at 5°C. After reacting for 6 hours, filtered, washed and dried to obtain Fluorinated photoinitiator, the yield is 86%.

[0046]Add 0.01mol oleic acid triglyceride and 0.03mol 10% sodium hydroxide solution to a 100mL round bottom flask, heat to make it fully react for 50min, then separate the liquids, wash the oil layer with excess 0.5mol / L sulfuric acid, and then divide it with 30mL saturated NaCl sol...

Embodiment 2

[0052] Add 30 mL of dichloromethane into a three-necked flask equipped with nitrogen protection and a magnetic stirring device, and 0.02 mol of 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl -1-acetone] and 0.02mol n-butylamine were dissolved in dichloromethane, and magnetically stirred at room temperature to mix them evenly. After 2 hours of reaction, the temperature was rapidly lowered, and 20 mL of dichloroethane and 0.04 mol of trifluoroacetyl chloride were slowly added to the reaction vessel in an ice-water bath. The fluorine-containing photoinitiator was obtained with a yield of 88%.

[0053] Add 0.02 mol oleic acid triglyceride and 0.06 mol 10% sodium hydroxide solution to a 100 mL round-bottomed flask, heat to make it fully react for 50 min, then separate the liquids, wash the oil layer with an excess of 0.5 mol / L sulfuric acid, and then separate with 30 mL saturated NaCl solution. After washing three times and drying, unsaturated oleic acid can be obtained (...

Embodiment 3

[0058] Add 35 mL of dichloromethane into a three-necked flask equipped with nitrogen protection and a magnetic stirring device, and 0.03 mol of 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl -1-acetone] and 0.03mol trimethylamine were dissolved in dichloromethane, and magnetically stirred at room temperature to make them mix uniformly. After 2 hours of reaction, the temperature was rapidly lowered, and 25 mL of dichloroethane and 0.06 mol of trifluoroacetyl chloride were slowly added to the reaction vessel in an ice-water bath. The fluorine-containing photoinitiator was obtained with a yield of 89%.

[0059] Add 0.03 mol oleic acid triglyceride and 0.09 mol 10% sodium hydroxide solution to a 100 mL round-bottomed flask, heat to make it fully react for 50 min, then separate the liquids, wash the oil layer with an excess of 0.5 mol / L sulfuric acid, and then separate with 30 mL saturated NaCl solution. After washing three times and drying, unsaturated oleic acid can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com