A method of suppressing splashing during converter steelmaking

A converter steelmaking and steel grade technology is applied in the field of suppressing splashing during converter steelmaking, and can solve problems such as increasing the consumption of iron and steel materials, reducing the amount of tapped steel, and interfering with the normal production operation of the converter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A 120-ton top-bottom double-blown converter in a steelmaking plant was blown according to the method of the present invention, and the process control was stable without any splashing. The specific conditions are shown in the table below.

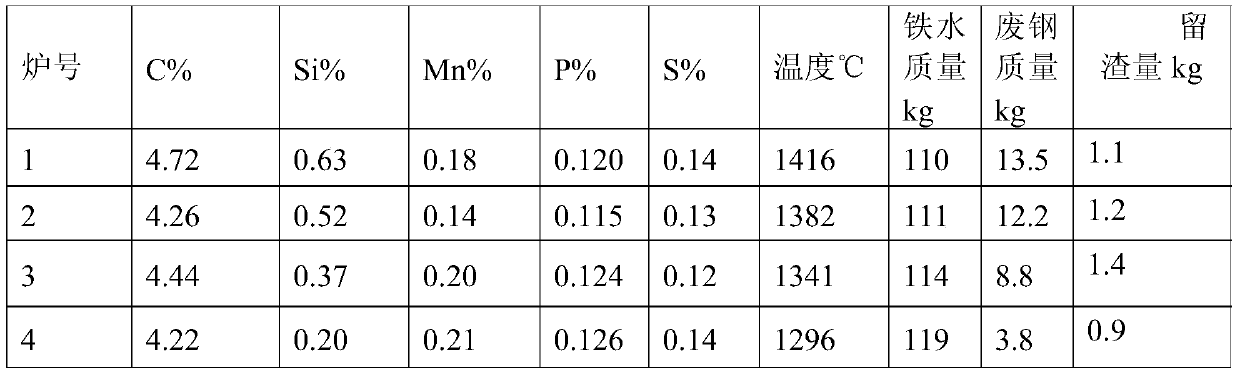

[0045] Table 1 shows the conditions of molten iron entering the furnace and the amount of steel scrap added:

[0046]

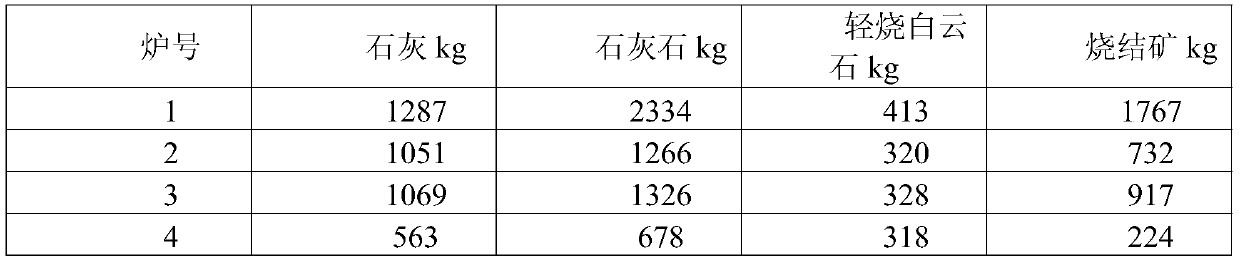

[0047] Table 2 is the first batch of charge additions:

[0048]

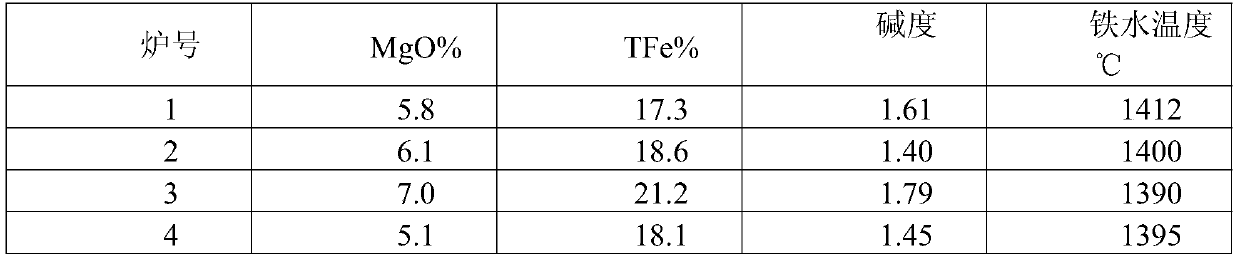

[0049] Table 3 shows the slag composition and molten iron temperature at the end of the silicomanganese oxidation period:

[0050]

[0051] Table 4 is the second batch of charge addition:

[0052]

[0053]

[0054] Table 5 final slag composition and end point carbon content:

[0055] furnace number MgO% TFe% Alkalinity End point C% 1 9.0 16.6 3.12 0.12 2 9.1 17.5 2.93 0.11 3 8.8 18.1 3.21 0.13 4 9.4 19.6 3.31 0.14

[0056] The invention provides a method for suppressing spattering in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com