A garment interlining with far-infrared function and its production method

A production method and far-infrared technology, applied in the field of clothing interlining, can solve the problems of inability to broaden the far-infrared function, limited far-infrared function of textiles, and low far-infrared emissivity, so as to be beneficial to human health, realize breathability and Far-infrared radiation, the effect of improving far-infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

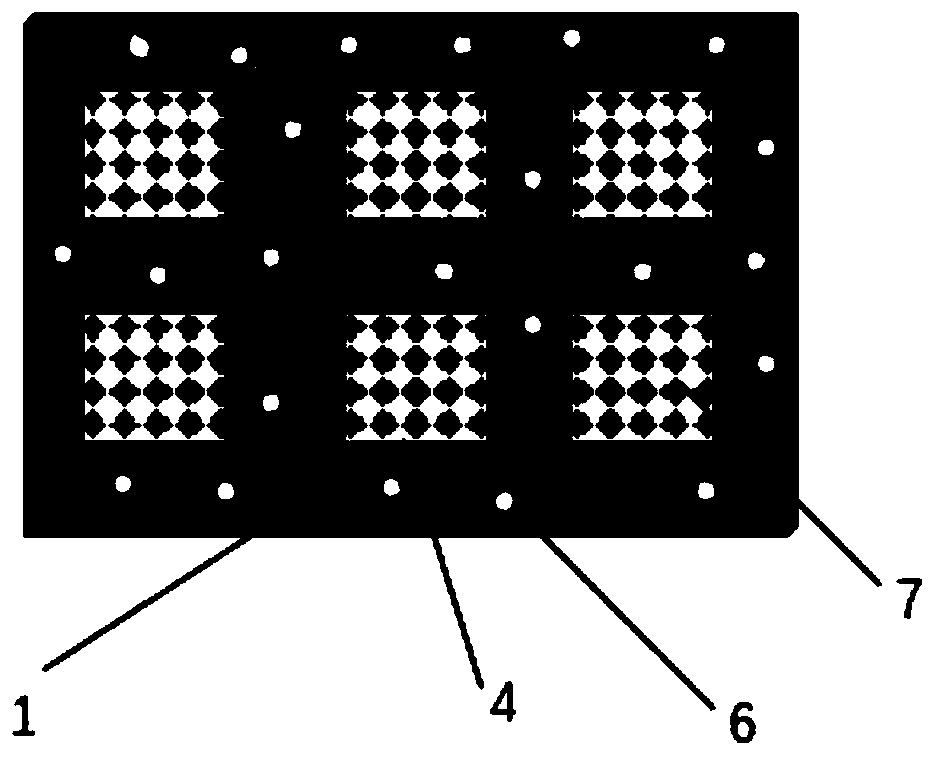

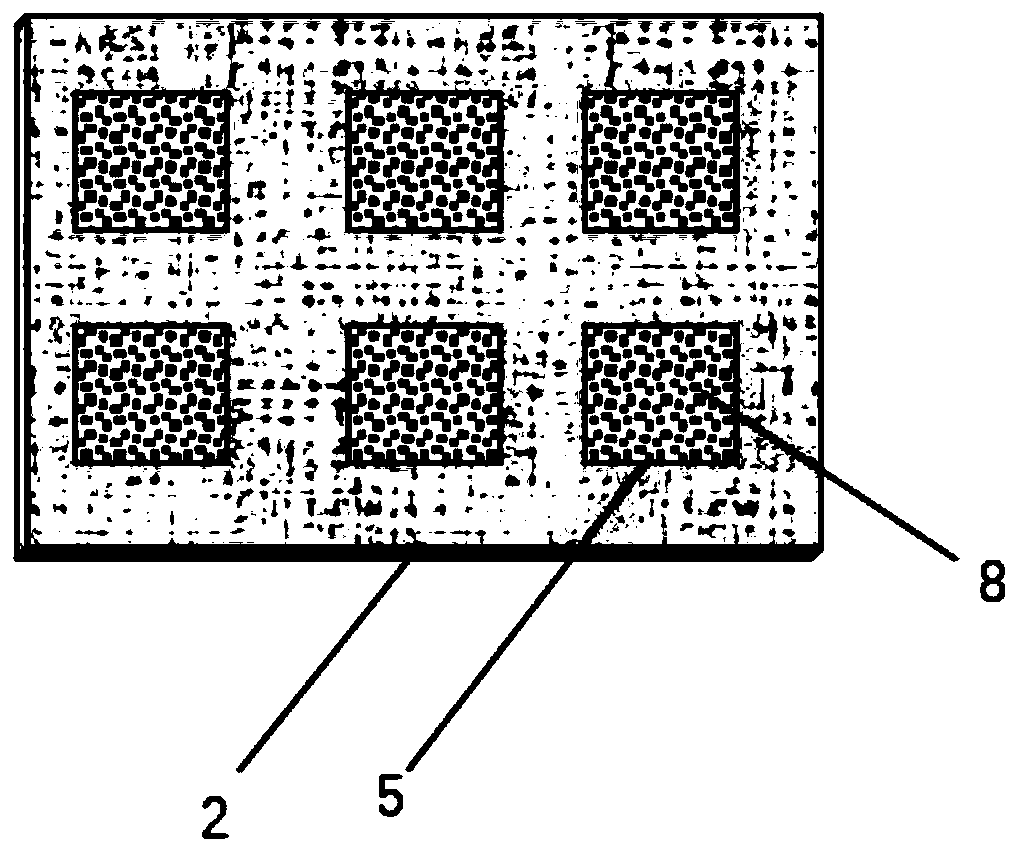

[0043] A production method of a garment interlining with far-infrared function, the production of the garment interlining includes the preparation of the upper knitted fabric, the preparation of the middle woven fabric, the compounding of the upper knitted fabric and the middle woven fabric, and the fusion of the composite fabric through the melt-blown process. The process of obtaining the finished garment interlining after the bottom surface is melt-blown. The far-infrared clothing interlining that the present embodiment produces is as attached Figure 1-4 Shown, its specific production process and steps are as follows:

[0044] 1) Preparation of the upper knitted fabric: using PET slices as the main raw material, the far-infrared radiation mullite powder is made into mullite masterbatch and PET slices are sent to the screw extruder for blending and melting to make spinning melt After being filtered by the melt filter, it is sent into the spinning box through the melt pipeli...

Embodiment 2

[0053] A method for producing a garment interlining with far-infrared function, the production of the garment interlining includes the preparation of the upper knitted fabric, the preparation of the middle woven fabric, the compounding of the upper knitted fabric and the middle woven fabric, and the fusion of the composite fabric through the melt-blown process. The process of obtaining the finished garment interlining after the bottom surface is melt-blown. The far-infrared clothing interlining that the present embodiment produces is as attached Figure 3-6 Shown, its specific production process and steps are as follows:

[0054]1) Preparation of the upper knitted fabric: using PET slices as the main raw material, the far-infrared radiation mullite powder is made into mullite masterbatch and PET slices are sent to the screw extruder for blending and melting to make spinning melt After being filtered by the melt filter, it is sent into the spinning box through the melt pipelin...

Embodiment 3

[0063] A production method of a garment interlining with far-infrared function, the production of the garment interlining includes the preparation of the upper knitted fabric, the preparation of the middle woven fabric, the compounding of the upper knitted fabric and the middle woven fabric, and the fusion of the composite fabric through the melt-blown process. The process of obtaining the finished garment interlining after the bottom surface is melt-blown. The far-infrared clothing interlining that the present embodiment produces is as attached Figure 3-4 , shown in 7-8, its specific production process and steps are as follows:

[0064] 1) Preparation of the upper knitted fabric: using PET slices as the main raw material, the far-infrared radiation mullite powder is made into mullite masterbatch and PET slices are sent to the screw extruder for blending and melting to make spinning melt After being filtered by the melt filter, it is sent into the spinning box through the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com