Deoiling net and processing method thereof

An oil net and oil layer technology, applied in the field of oil fume purification, can solve problems such as life-threatening safety, and achieve the effect of increasing the condensation stroke and reducing the oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

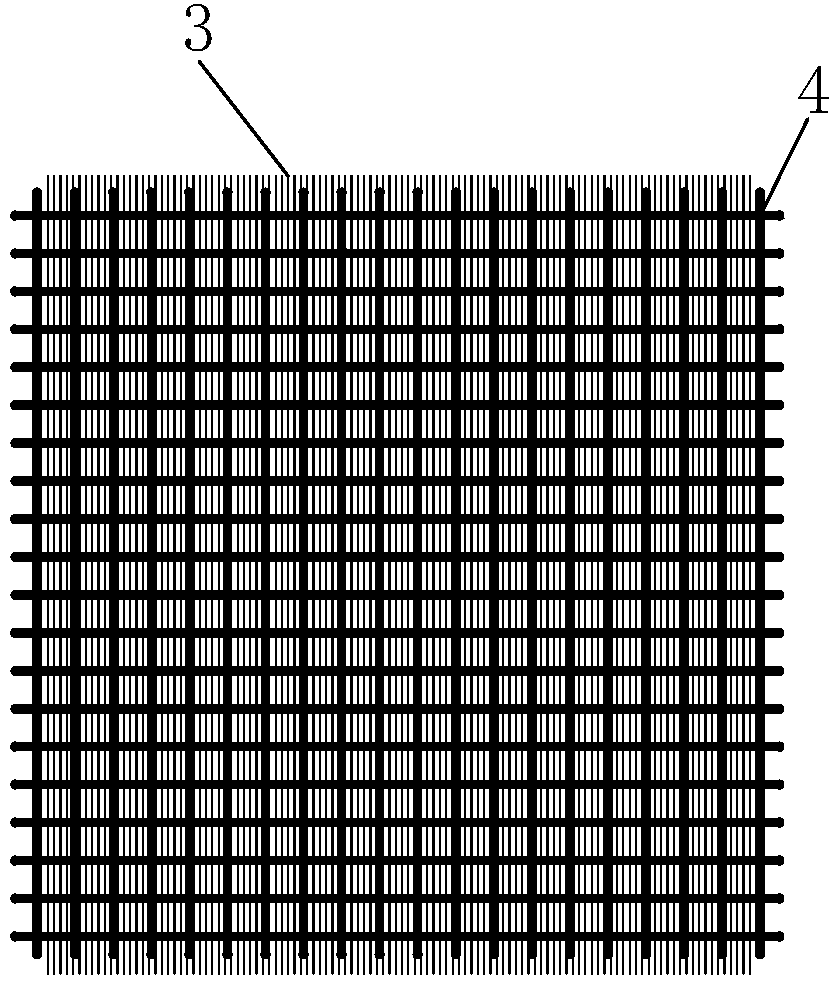

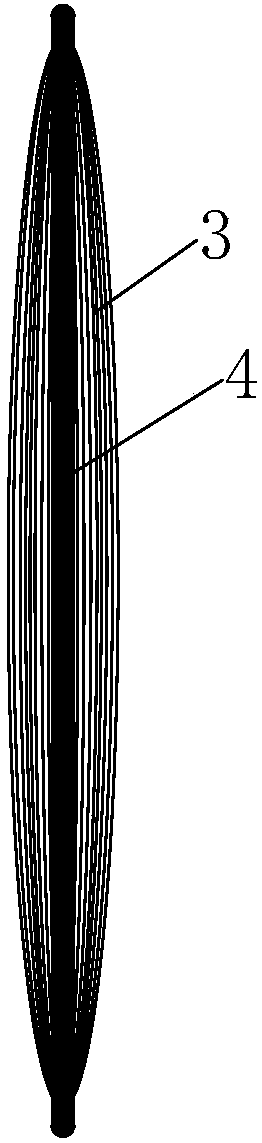

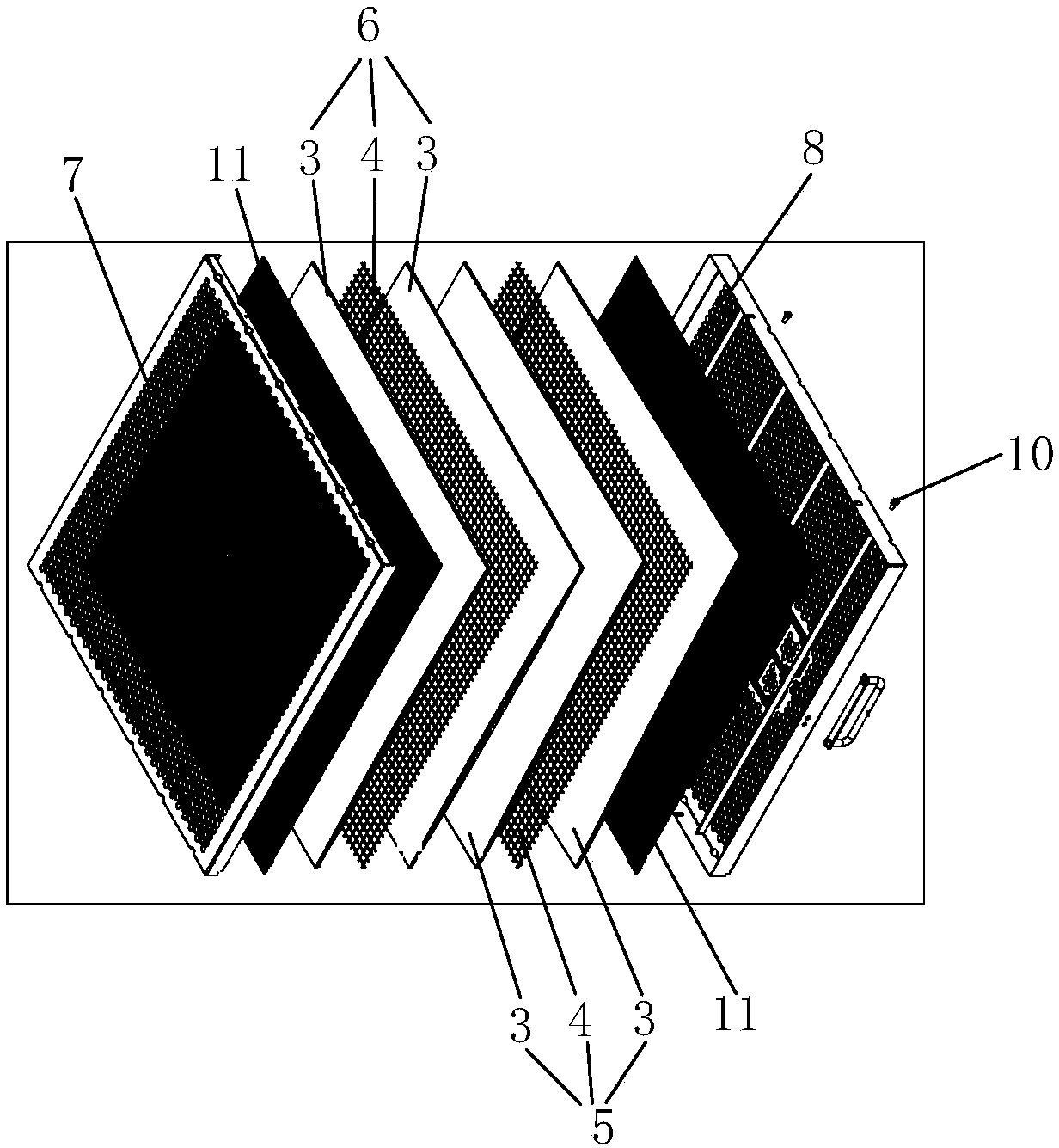

[0029] to combine Figure 1-7 The shown oil removal net includes a shell, and several air holes 1 are provided on the front and back of the shell, and oil outlet holes 2 are set at the corners of the top and bottom of the shell. The housing of the present invention has many specific structures, for example: the housing includes an inner shell plate 7 and an outer shell plate 8, such as Figure 3-5 As shown, the inner shell plate 7 and the outer shell plate 8 are two square plates arranged side by side, and the edges around the inner shell plate 7 and the outer shell plate 8 are oppositely bent to form a connecting portion 9, that is to say, the inner shell plate 7 The edge of the outer shell plate 8 is bent toward the direction of the outer shell plate 8, and the edge of the outer shell plate 8 is bent toward the direction of the inner shell plate 7. After bending, the edges of the inner shell plate 7 and the outer shell plate 8 constitute a structure for connecting the two T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com