Space charge measurement device and measurement method suitable for interface effect research

A space charge and interface effect technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as lack of impact mechanism, achieve the effect of ensuring work stability, easy operation, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

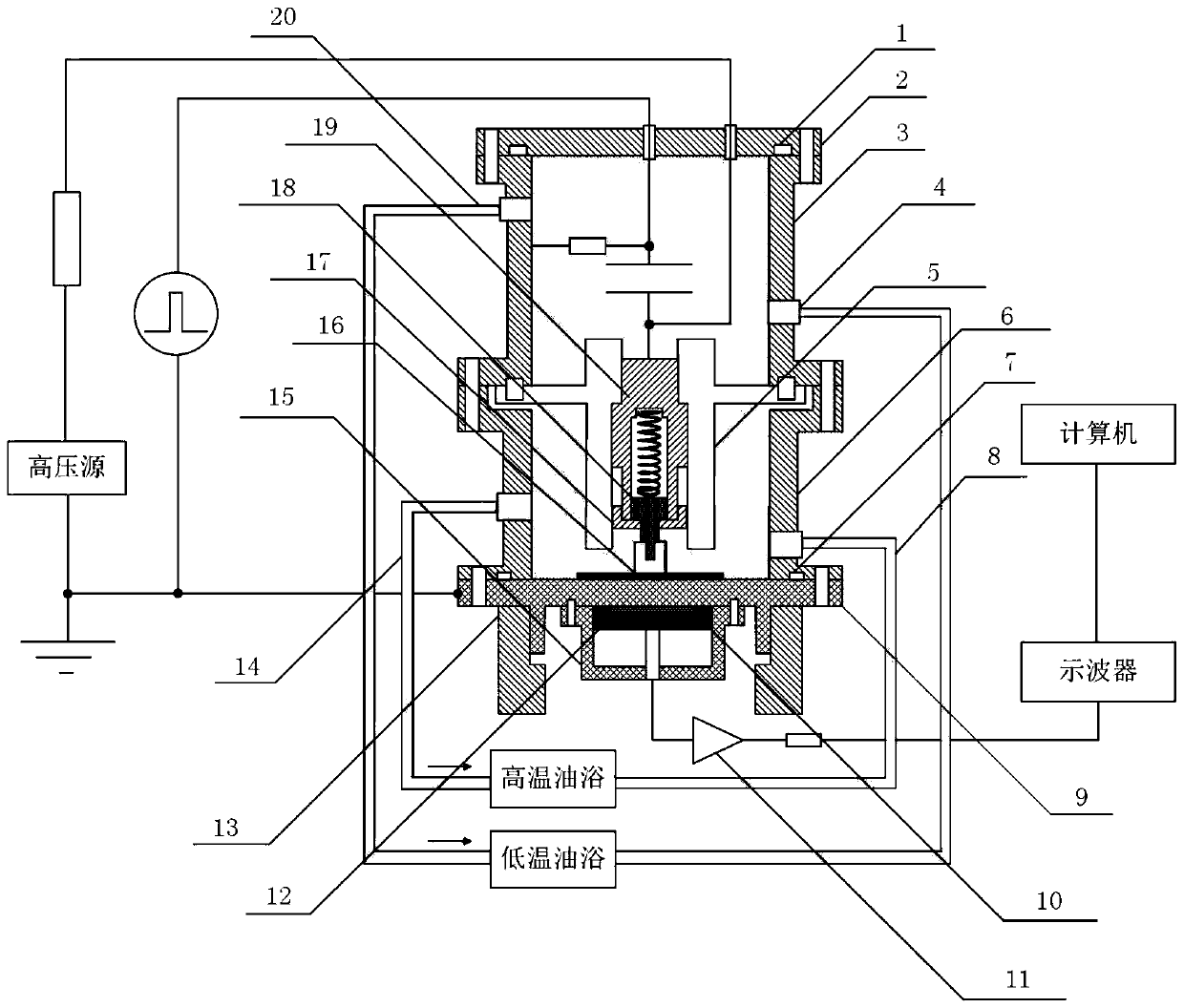

[0031] The present invention is applicable to the space charge testing method of interface effect research, comprises the following steps:

[0032] 1) According to the degree of close contact between the sample and the upper electrode required for the test, select a spring with a suitable wire diameter and length and place it inside the electrode barrel, press the upper electrode seat on the lower part of the spring, and screw the electrode cap 17 to the electrode barrel 19 superior;

[0033] 2) Insert the assembled spring electrode into the inside of the PTFE separator 5, and fix the hexagonal screws through the two through holes on the side of the PTFE separator 5 to the two threaded holes on the side of the electrode cylinder 19, which can effectively Prevent the rotation of the electrode cylinder 19 inside the PTFE separator 5, and fix the PTFE separator 5 and the shell of the pulse coupling circuit cavity 3 together by hexagonal screws;

[0034] 3) Screw the upper electr...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is only:

[0042] During the measurement process, according to the tightness of contact between the sample and the upper electrode 16 required for the test, that is, the force exerted by the upper electrode on the sample, the wire diameter and length of the spring in step 1) are changed to achieve different pressures and different temperature conditions Under the space charge test.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is only:

[0045] In the measurement process, if it is necessary to study the influence of different electrode materials on space charge injection, unscrew the original upper electrode 16 in step 3), and screw on the required test electrode, so that space charge injection can be achieved when the electrode materials are different. characteristic tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com