Molecular-dynamics simulation method of predicting diffusion coefficient of combustion process of nano-multilayer film

A molecular dynamics, nano-multilayer technology, applied in special data processing applications, electrical digital data processing, CAD numerical modeling, etc., can solve the difficult-to-measure diffusion coefficient and atomic diffusion behavior, diffusion phenomenon and phase transition behavior Difficult to observe and analyze problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

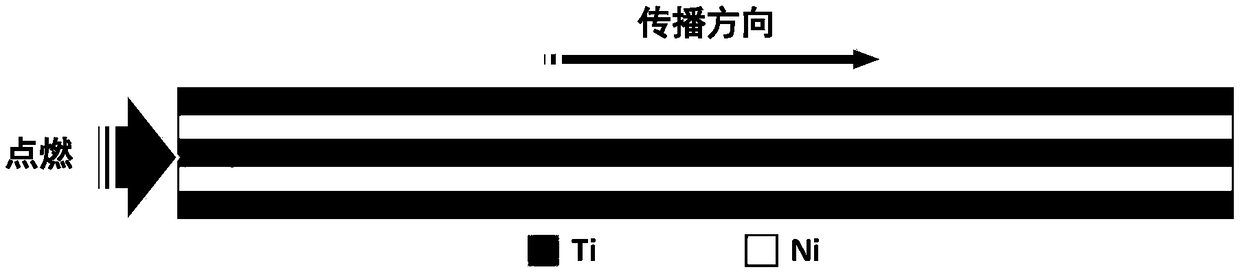

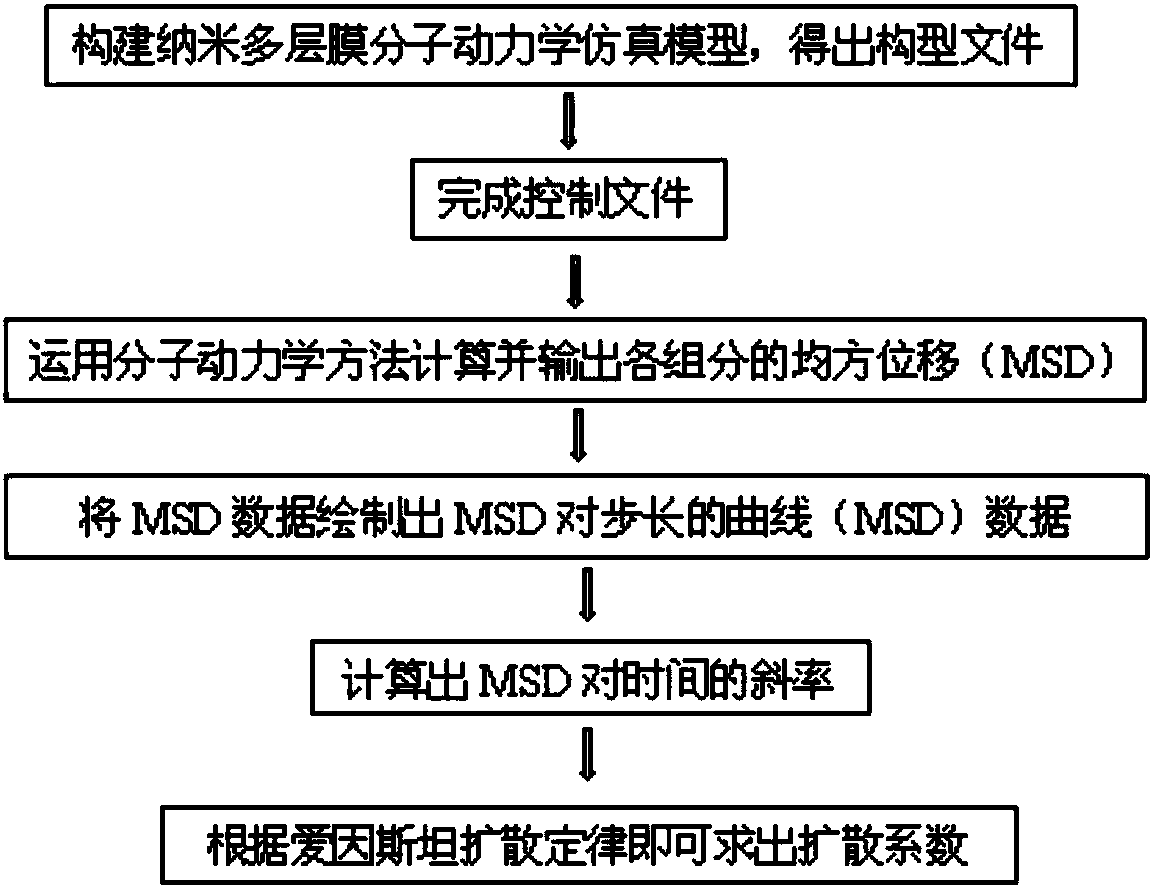

[0030] In the embodiment of the present invention, figure 1 Schematic diagram of the structure of the reactive nano-multilayer film. figure 2 It is a schematic flow diagram of the method of the present invention, such as figure 2 As shown, the method of predicting the diffusion coefficient of the reaction nano-multilayer film combustion process based on molecular mechanics simulation can be summarized into the following steps: Step 1: Construct the molecular dynamics simulation model of the nano-multilayer film, and obtain the configuration file, namely Data file; Step 2: Complete the control file, that is, the in file; Step 3: Use the molecular dynamics method to calculate and output the MSD data of the mean square displacement of each component; Step 4: Draw the MSD data into a curve of MSD versus step size; Step Five: Calculate the slope of MSD versus time; Step six: Calculate the diffusion coefficient according to Einstein's law of diffusion.

[0031] This example requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com