Gas supply device capable of measuring flow rate, flowmeter, and flow rate measuring method

A technology of gas supply and flow, applied in the direction of measuring flow/mass flow, measuring devices, volume measuring instruments/methods, etc., can solve problems such as hindering space saving, volume containing errors, etc., and achieve the effect of space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

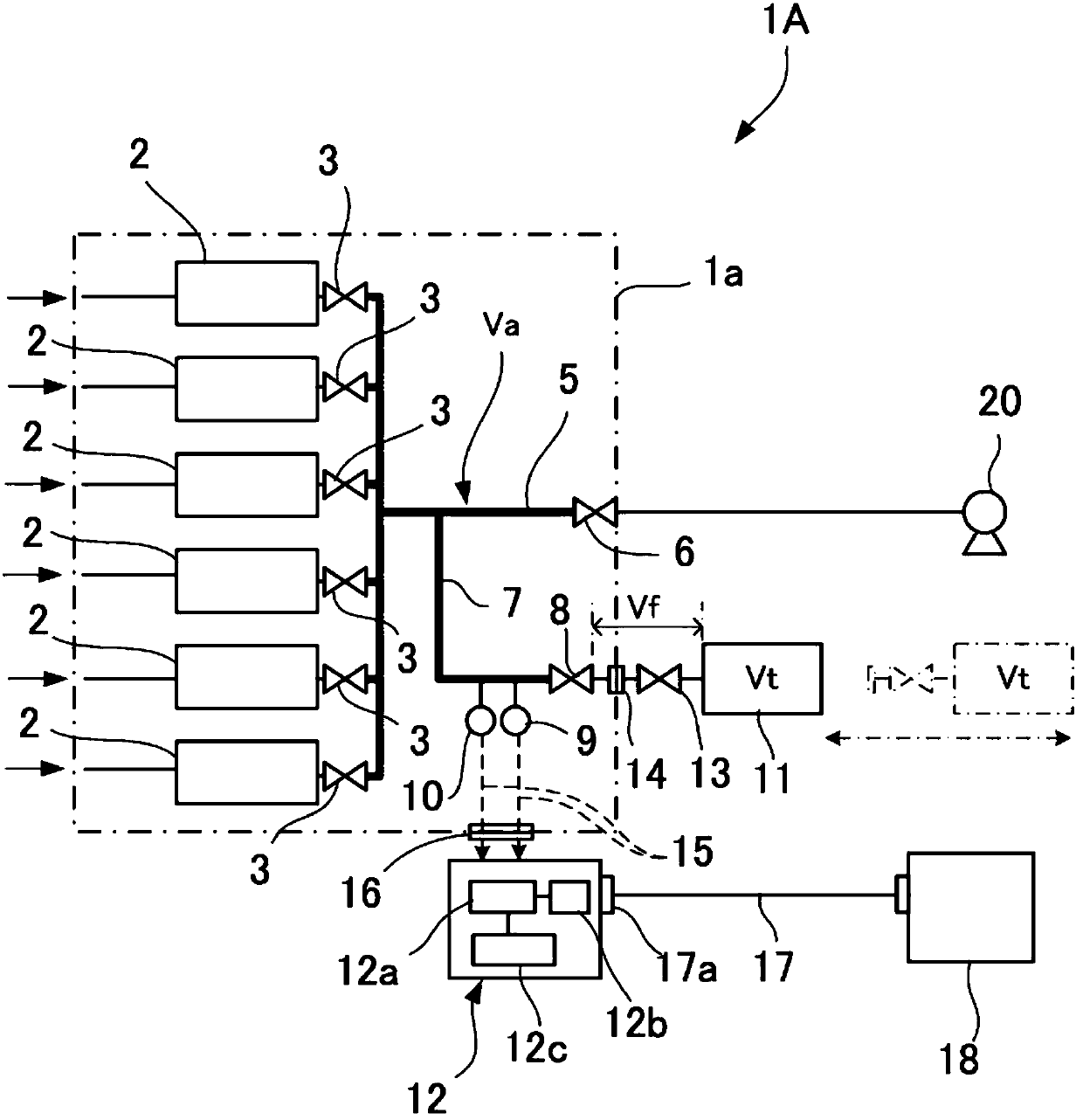

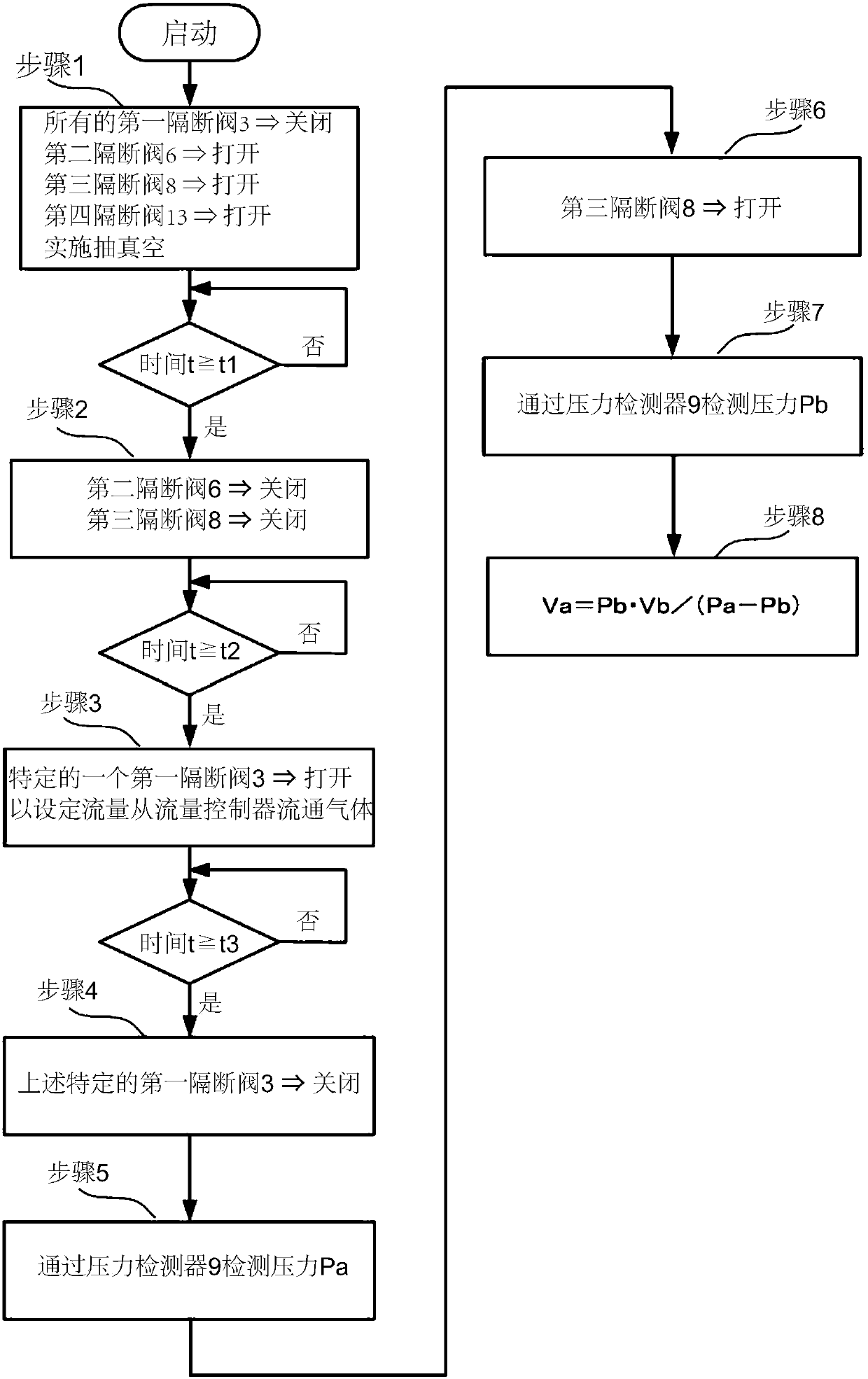

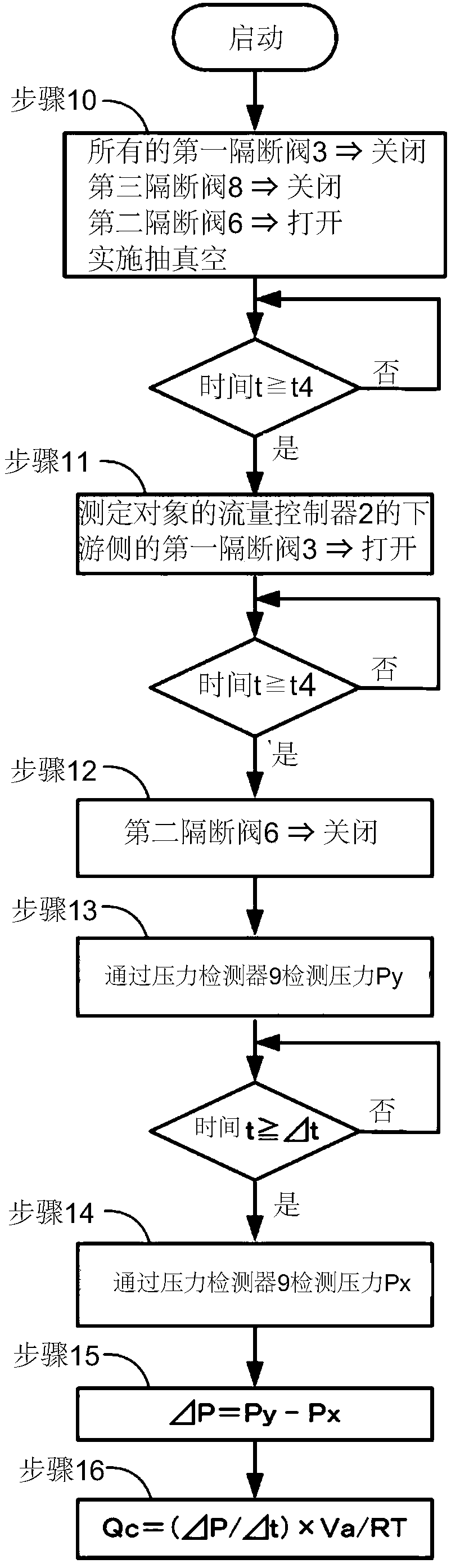

[0053] For the embodiments of the present invention, refer to Figure 1 to Figure 6 Be explained. In addition, in all drawings, the same code|symbol is attached|subjected to the same or similar component.

[0054] figure 1 It is a block diagram showing the first embodiment of the present invention. The gas supply device 1A capable of measuring the flow rate is equipped with: a plurality of flow controllers 2, which control the flow rate of the gas flowing through; a first shutoff valve 3, which is arranged downstream of the flow controller 2; A first flow path 5 communicating with the downstream side of the first block valve; a second flow path 7 branching from the first flow path 5 between the first block valve 3 and the second block valve 6; the third block valve Valve 8, which is arranged in the second flow path 7; pressure detector 9, which detects the pressure in the flow path surrounded by the first block valve 3, the second block valve 6 and the third block valve 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com