Sole sterilization drying unit

A drying unit and one-way valve technology, applied in the cleaning, chemical, and cleaning equipment of boots and shoes, can solve the problems of high manufacturing cost, cumbersome assembly process, lack of disinfection unit for shoe disinfection, etc., and achieve compact layout and simple structure , no power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

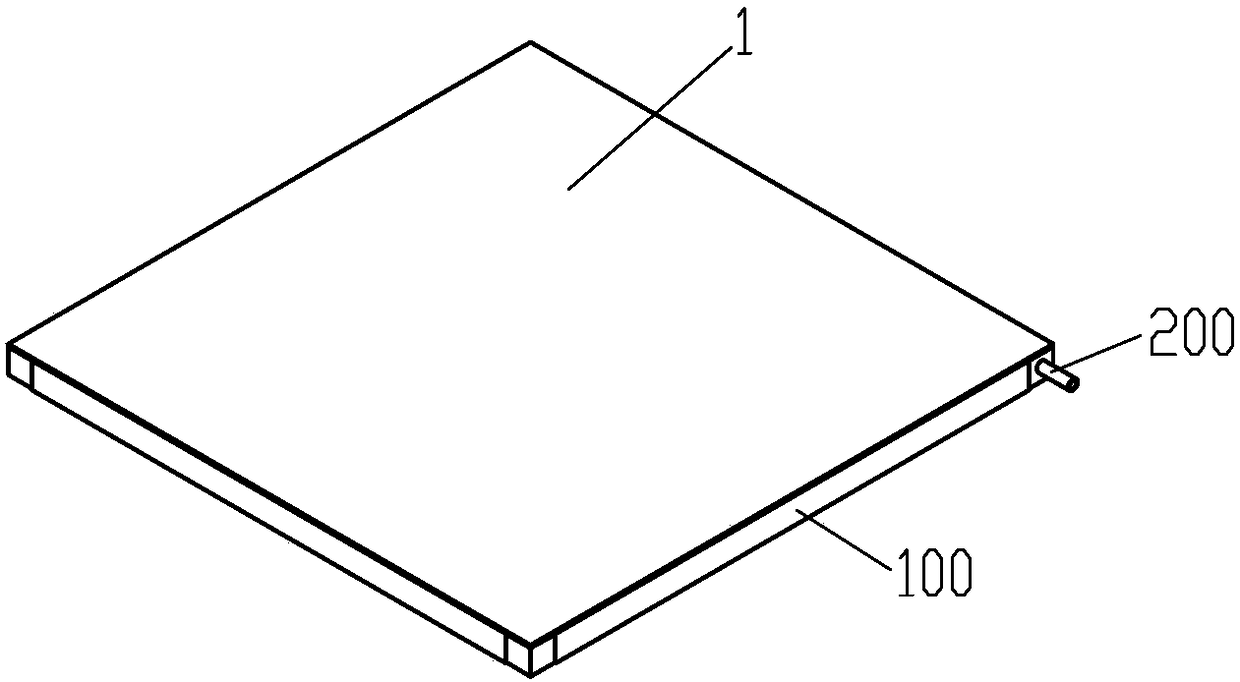

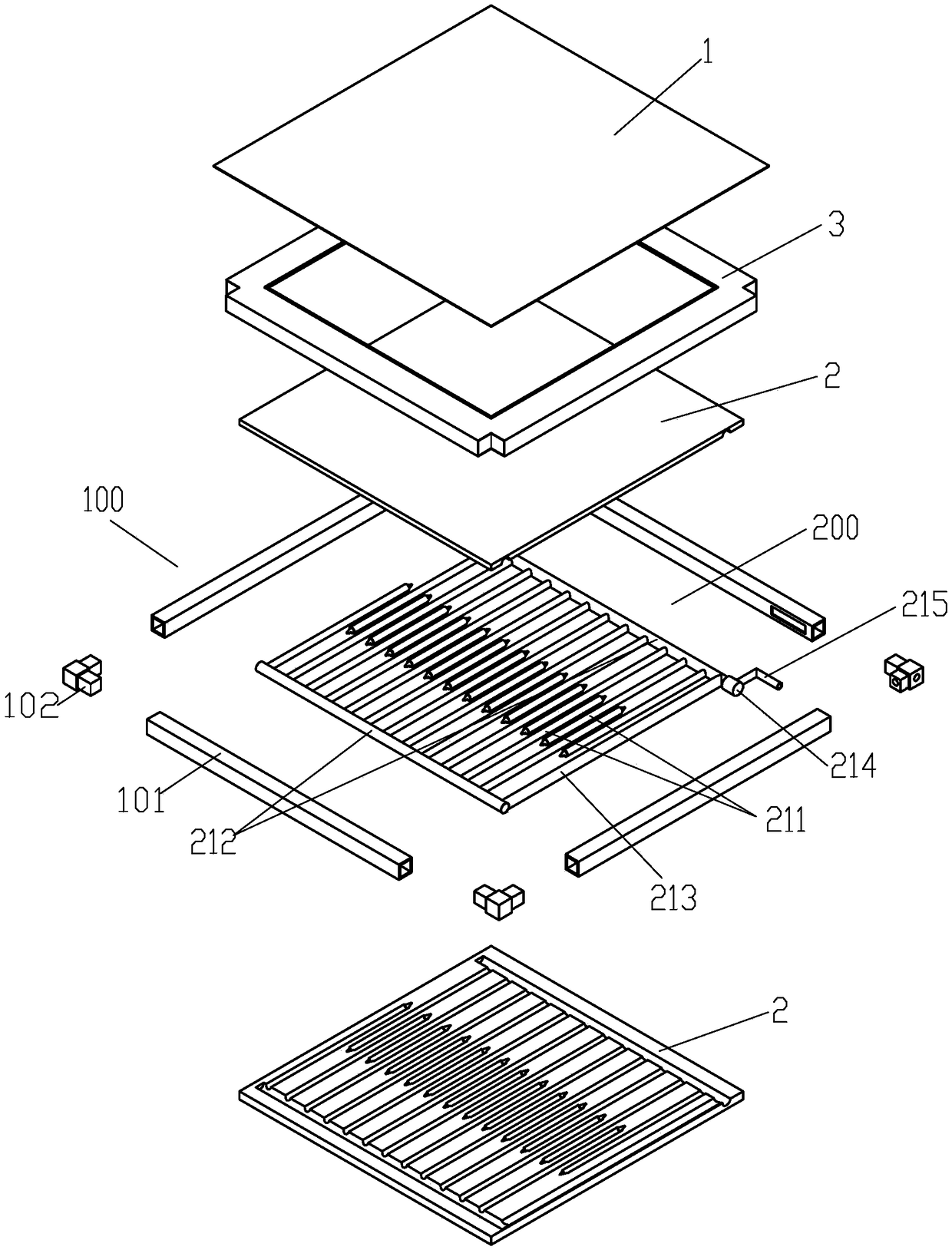

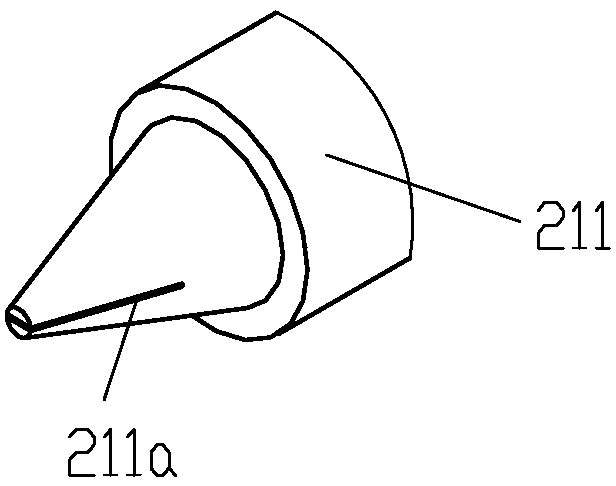

[0019] Example 1, see figure 1 , figure 2 , a shoe sole disinfection and drying unit, comprising a wiping surface layer 1 made of soft water-absorbing material, the wiping surface layer 1 is fixed on the upper surface of the surface layer fixing frame 100 through the periphery; the surface layer fixing frame 100 is provided with a disinfection humidification The device 200, the disinfecting and humidifying device 200 includes a plurality of liquid-feeding pipes 211 to form a liquid-feeding pipe row of a pipe structure. The liquid-feeding pipe row is made of soft elastic material. The liquid-feeding pipe 211 is horizontally suspended. The overhanging distal end constitutes the liquid outlet, and the liquid outlet has a one-way valve structure.

[0020] Wherein, the disinfection and humidification device 200 is provided with two oppositely arranged liquid feeding pipe rows, the liquid feeding pipe row includes a main pipe 212, and the two main pipes 212 are connected by a comm...

Embodiment 2

[0022] Example 2, see image 3 , a liquid discharge device 300 is provided below the disinfection and humidification device 200, the liquid discharge device has the same pipe structure as the disinfection and humidification device 200, and the discharge pipe 301 of the liquid discharge device is made of soft elastic material, and The bottom of the discharge pipe is closed, and there are multiple drainage inlet holes distributed on the pipe wall of the discharge pipe; a discharge check valve 302 is provided on the outlet section of the confluence main pipe of the two rows of discharge pipes, and the discharge pipes are wrapped In the two effusion sponges, the sponge pad 2 immediately above the drainage device 300 constitutes one of the effusion sponges, and the other effusion sponge is located below the drainage device 300. The groove in which the pipe row is embedded.

[0023] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com