Batch mixing and uniform shaking device for chemical drugs of laboratory

A chemical and laboratory technology, applied in mixers, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low mixing efficiency, inconvenient movement of equipment, and poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

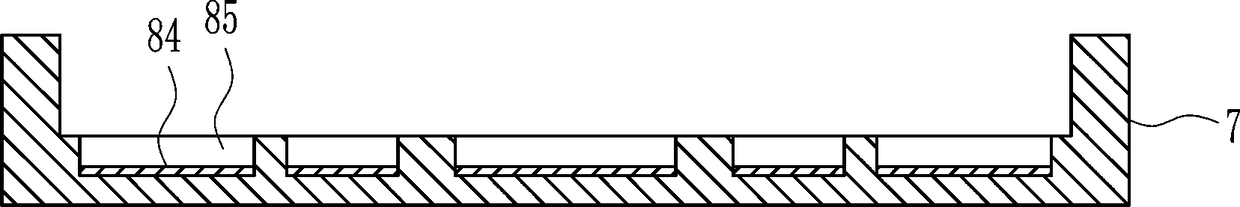

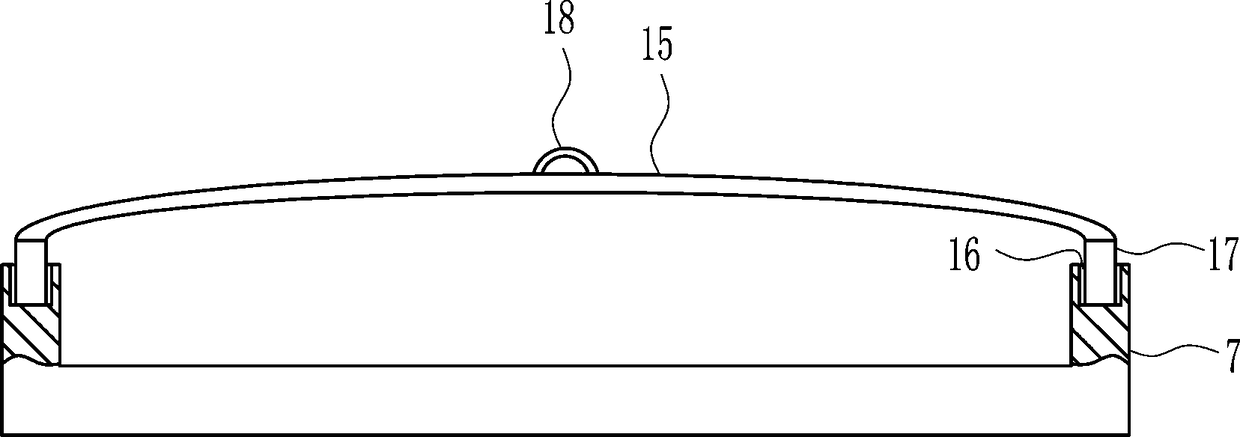

[0037] A batch mixing and shaking device for laboratory chemicals, such as Figure 1-9 As shown, it includes a fixed frame 1, a slider 2, a slide rail 3, a motor 4, a first rotating shaft 5, a moving device 6, an annular frame 7 and a protective heat preservation device 8, and the middle part of the fixed frame 1 is provided with a motor 4 and a motor 4 The bottom of the fixed frame 1 on the left and right sides is symmetrically provided with slide rails 3, the slide rails 3 on the left and right sides are all provided with sliders 2, the motor 4 is connected with the first rotating shaft 5, and the upper end of the first rotating shaft 5 is provided with a movable The top of the device 6 and the moving device 6 is connected with an annular frame 7 , and the inner bottom of the annular frame 7 is provided with a protective heat preservation device 8 .

Embodiment 2

[0039] A batch mixing and shaking device for laboratory chemicals, such as Figure 1-9As shown, it includes a fixed frame 1, a slider 2, a slide rail 3, a motor 4, a first rotating shaft 5, a moving device 6, an annular frame 7 and a protective heat preservation device 8, and the middle part of the fixed frame 1 is provided with a motor 4 and a motor 4 The bottom of the fixed frame 1 on the left and right sides is symmetrically provided with slide rails 3, the slide rails 3 on the left and right sides are all provided with sliders 2, the motor 4 is connected with the first rotating shaft 5, and the upper end of the first rotating shaft 5 is provided with a movable The top of the device 6 and the moving device 6 is connected with an annular frame 7 , and the inner bottom of the annular frame 7 is provided with a protective heat preservation device 8 .

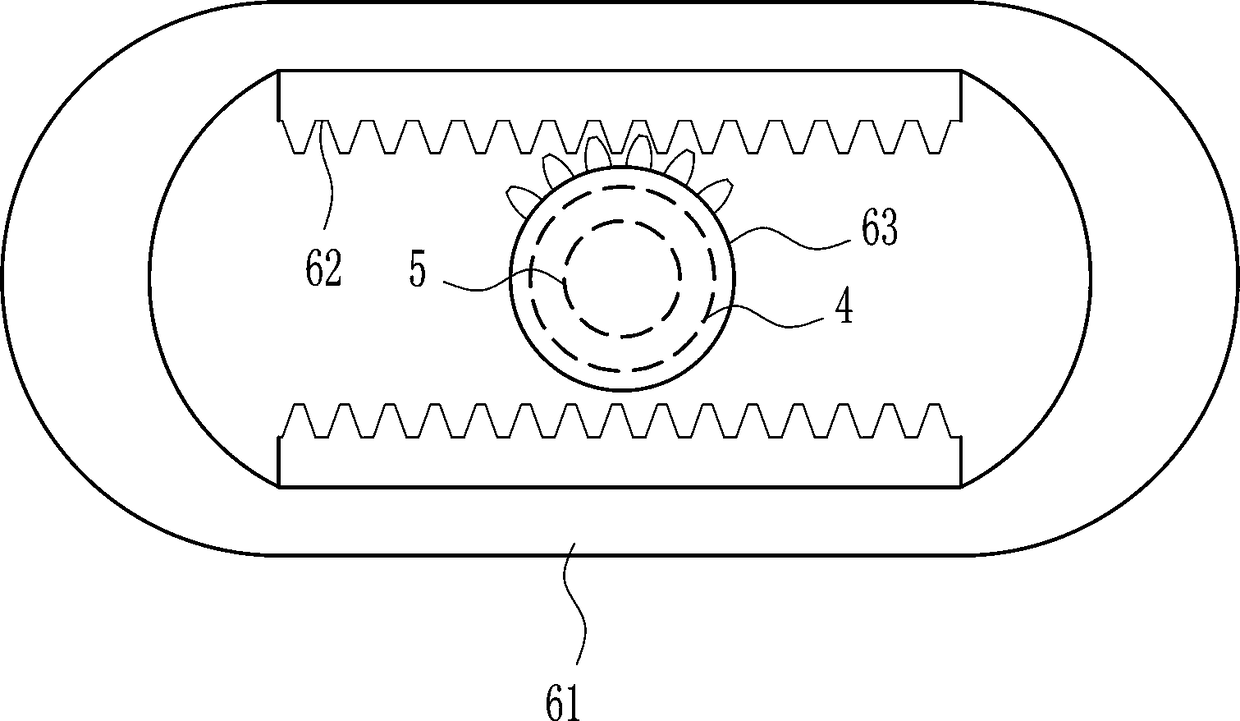

[0040] The moving device 6 includes a moving frame 61, an inner ring gear 62 and an outer ring gear 63. The upper end of the f...

Embodiment 3

[0042] A batch mixing and shaking device for laboratory chemicals, such as Figure 1-9 As shown, it includes a fixed frame 1, a slider 2, a slide rail 3, a motor 4, a first rotating shaft 5, a moving device 6, an annular frame 7 and a protective heat preservation device 8, and the middle part of the fixed frame 1 is provided with a motor 4 and a motor 4 The bottom of the fixed frame 1 on the left and right sides is symmetrically provided with slide rails 3, the slide rails 3 on the left and right sides are all provided with sliders 2, the motor 4 is connected with the first rotating shaft 5, and the upper end of the first rotating shaft 5 is provided with a movable The top of the device 6 and the moving device 6 is connected with an annular frame 7 , and the inner bottom of the annular frame 7 is provided with a protective heat preservation device 8 .

[0043] The moving device 6 includes a moving frame 61, an inner ring gear 62 and an outer ring gear 63. The upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com