Compounded solvent for separating cycloalkanes and aromatic hydrocarbons from naphtha, and preparation method and application thereof

A technology for naphtha and naphthenic hydrocarbons, which is applied to a compound solvent for separating naphthenic hydrocarbons and aromatic hydrocarbons from naphtha and the fields of preparation and application thereof, can solve the problem of increased demand for naphtha and unsatisfactory naphthenic hydrocarbons. Use and other issues to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides the preparation method of the above-mentioned compound solvent for separating naphthenes and aromatics from naphtha, the preparation method comprising the following steps:

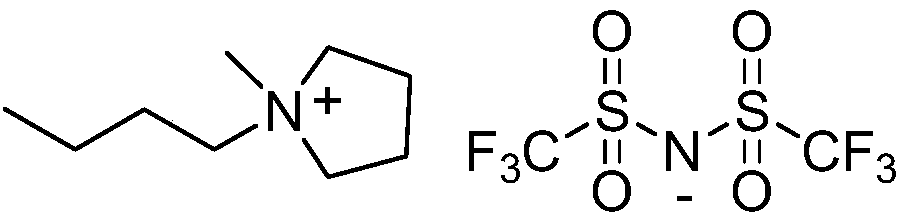

[0057] Keep the temperature of sulfolane constant at 60-80°C, then dropwise add 1-n-butyl-1-methylpyrrolidinium bis(trifluoromethanesulfonyl)imide salt, and stir until the compound solvent is evenly mixed;

[0058] Wherein, the mass ratio of the 1-n-butyl-1-methylpyrrolidinium bis(trifluoromethanesulfonyl)imide salt to sulfolane is 1:2-100.

[0059] The present invention further provides a method for separating cycloalkanes and aromatics from naphtha with a compound solvent. The method is to contact the compound solvent with the naphtha in countercurrent, and perform a liquid-liquid extraction process to obtain the ane naphtha. A mixture of by-product compound solvents and cycloalkanes and aromatics;

[0060] Wherein, the compound solvent includes 1-n-butyl-1-met...

Embodiment 1

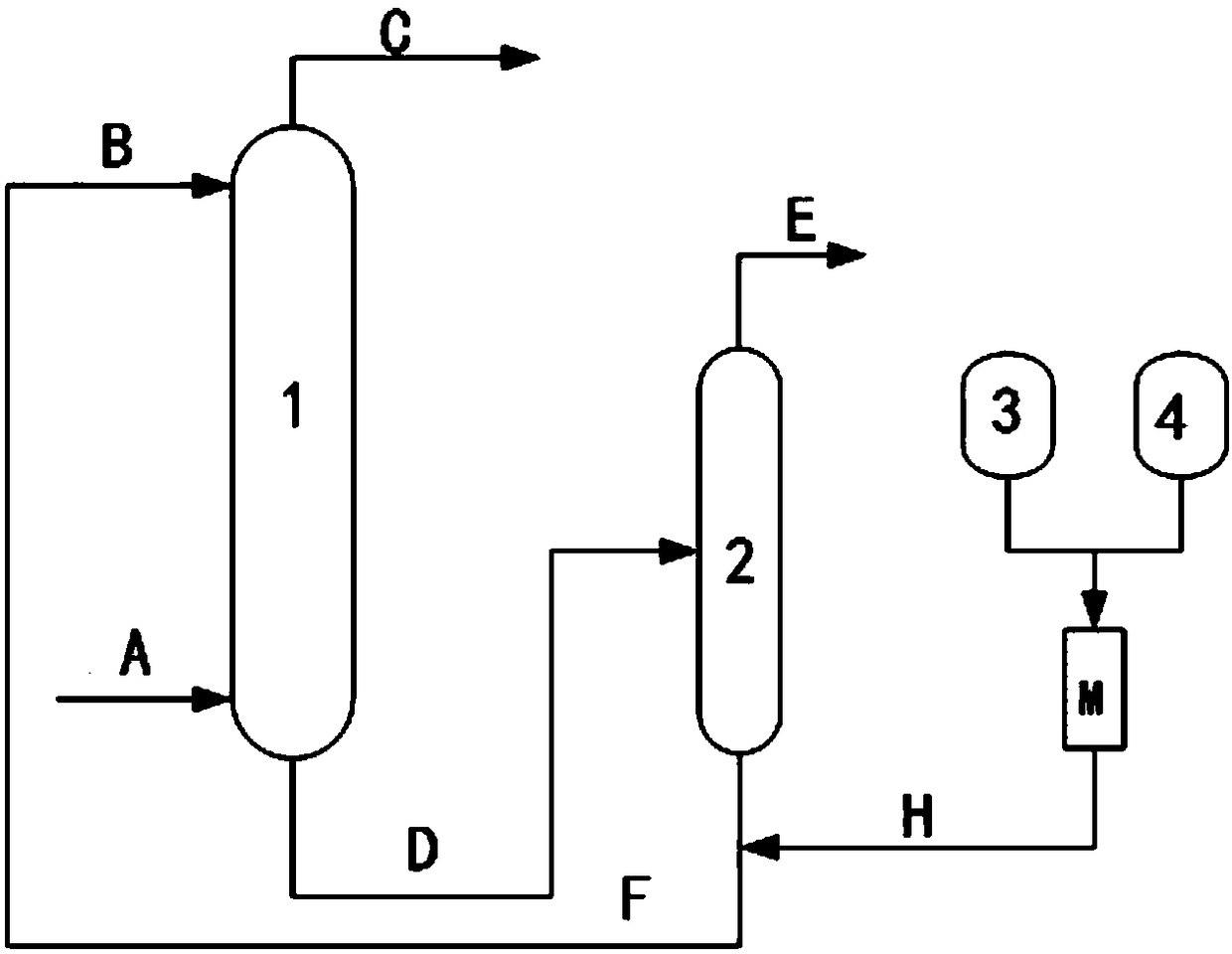

[0088] 1-butyl-1-methylpyrrole bistrifluoromethanesulfonimide salt and sulfolane are compounded to prepare a compound solvent, and the compounding ratio is ionic liquid: sulfolane=1:2 (quality), and the naphtha fraction is prepared according to figure 1 Extraction and separation are carried out according to the flow process. The ionic liquid and sulfolane are drawn from their respective storage tanks and enter the static mixer M. After being fully mixed, they are introduced from the top of the extraction tower 1, and are countercurrently contacted with the naphtha entering from the bottom of the extraction tower 1. ; After liquid-liquid extraction extraction, extraction tower 1 overhead flow is the naphtha (raffinate) that has removed part naphthenes and aromatics, and most of naphthenes and aromatics and whole compound solvent are together from extraction tower 1 The bottom of the tower is drawn to the vacuum distillation tower 2; after vacuum distillation, the compound solven...

Embodiment 2

[0091] This embodiment is basically the same as Embodiment 1, and the specific steps are as follows:

[0092] 1-butyl-1-methylpyrrole bistrifluoromethanesulfonimide salt and sulfolane are compounded to prepare a compound solvent, and the compounding ratio is ionic liquid: sulfolane=1:10 (quality), and the naphtha fraction is prepared according to figure 1 Extraction and separation are carried out according to the flow process. The ionic liquid and sulfolane are drawn from their respective storage tanks and enter the static mixer M. After being fully mixed, they are introduced from the top of the extraction tower 1, and are countercurrently contacted with the naphtha entering from the bottom of the extraction tower 1. ; After liquid-liquid extraction extraction, extraction tower 1 overhead flow is the naphtha (raffinate) that has removed part naphthenes and aromatics, and most of naphthenes and aromatics and whole compound solvent are together from extraction tower 1 The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com