Cloth cleaning equipment

A technology for cleaning equipment and cloth, which is applied to the configuration of textile material equipment, the processing of textile materials, and the processing of textile material drums. It can solve the problems of weak impact on the back of the cloth, affecting the processing effect of the cloth, and the inability to effectively clean the back of the cloth. , to achieve the effect of fast shedding, increasing the cleaning range and ensuring the production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

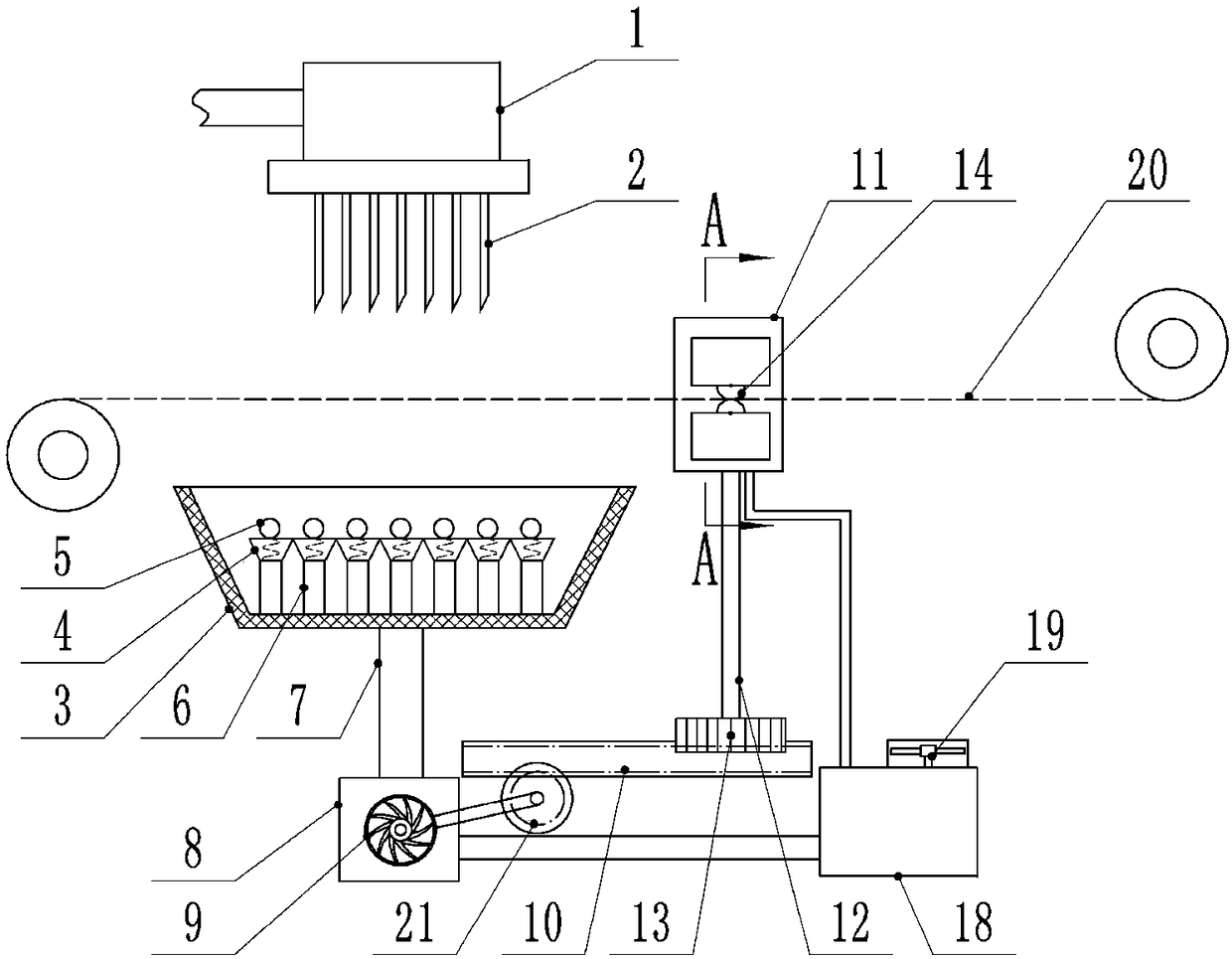

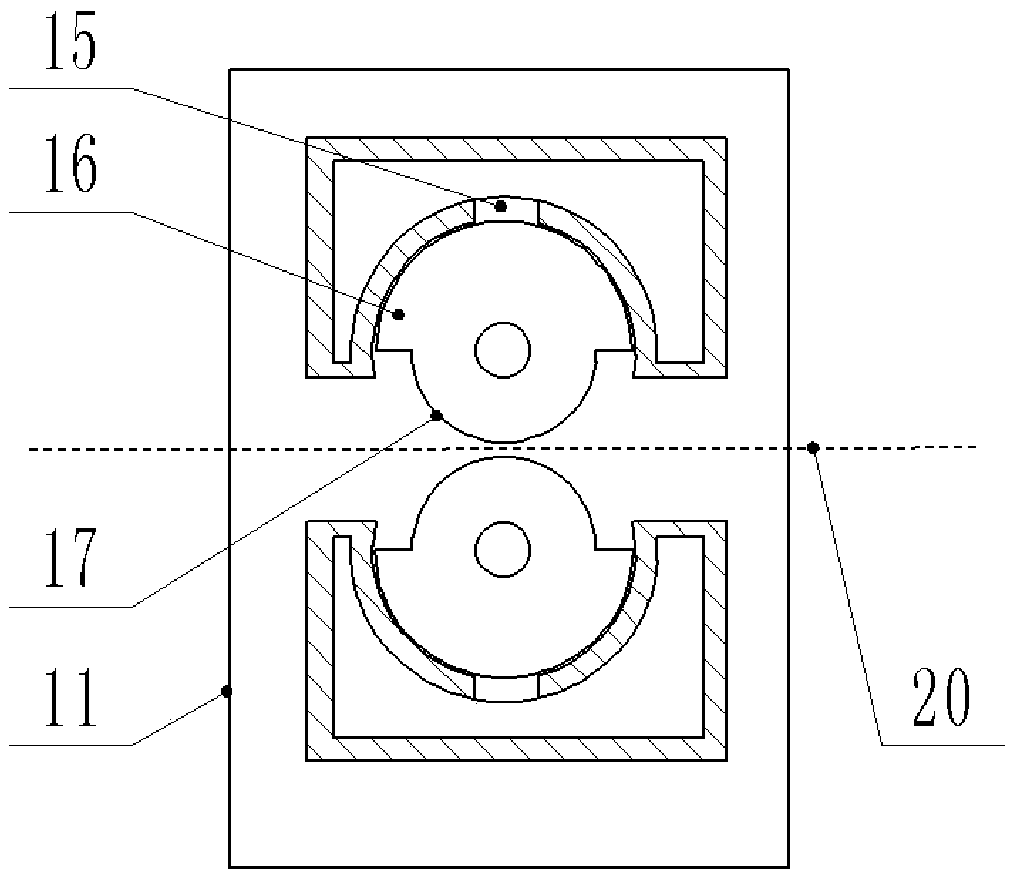

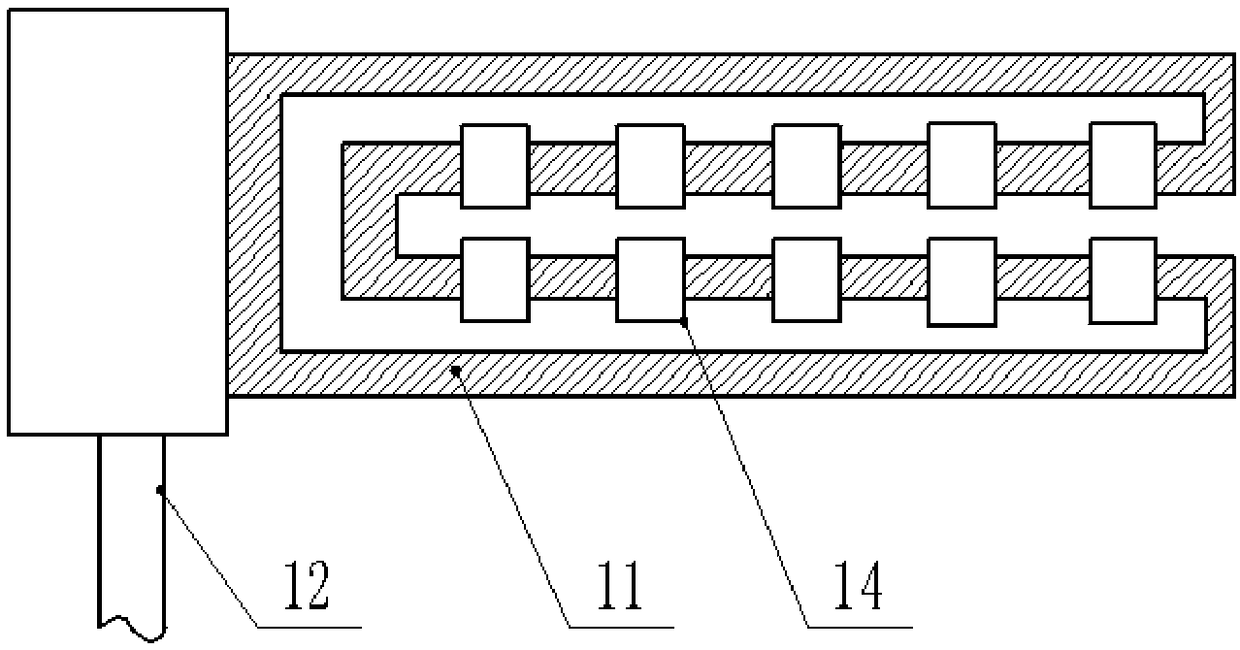

[0022] The reference signs in the accompanying drawings of the description include: nozzle 1, needle tube 2, water receiving tank 3, reflective plate 4, jumping ball 5, column 6, drain pipe 7, box body 8, turbine 9, rack 10, scraper 11, Fork 12, transmission gear 13, runner 14, through hole 15, large semicircular plate 16, small semicircular plate 17, water tank 18, negative pressure fan 19, cloth 20, driving gear 21.

[0023] Example figure 1 Shown: Cloth cleaning equipment, including transmission mechanism, water spray mechanism, reflection mechanism, cleaning mechanism and negative pressure mechanism.

[0024] The transmission mechanism is used for conveying the cloth 20, so that the cloth 20 is moved to the bottom of the water spray mechanism for cleaning. The structure of the transmission mechanism includes a driving roller and a driven roller, the driving roller i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com