Online real-time detection device and method for ore pulp density

A technology for real-time detection of pulp concentration, applied in measuring devices, sampling devices, instruments, etc., to achieve high detection accuracy, stable pipeline characteristics, and easy replacement and maintenance in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

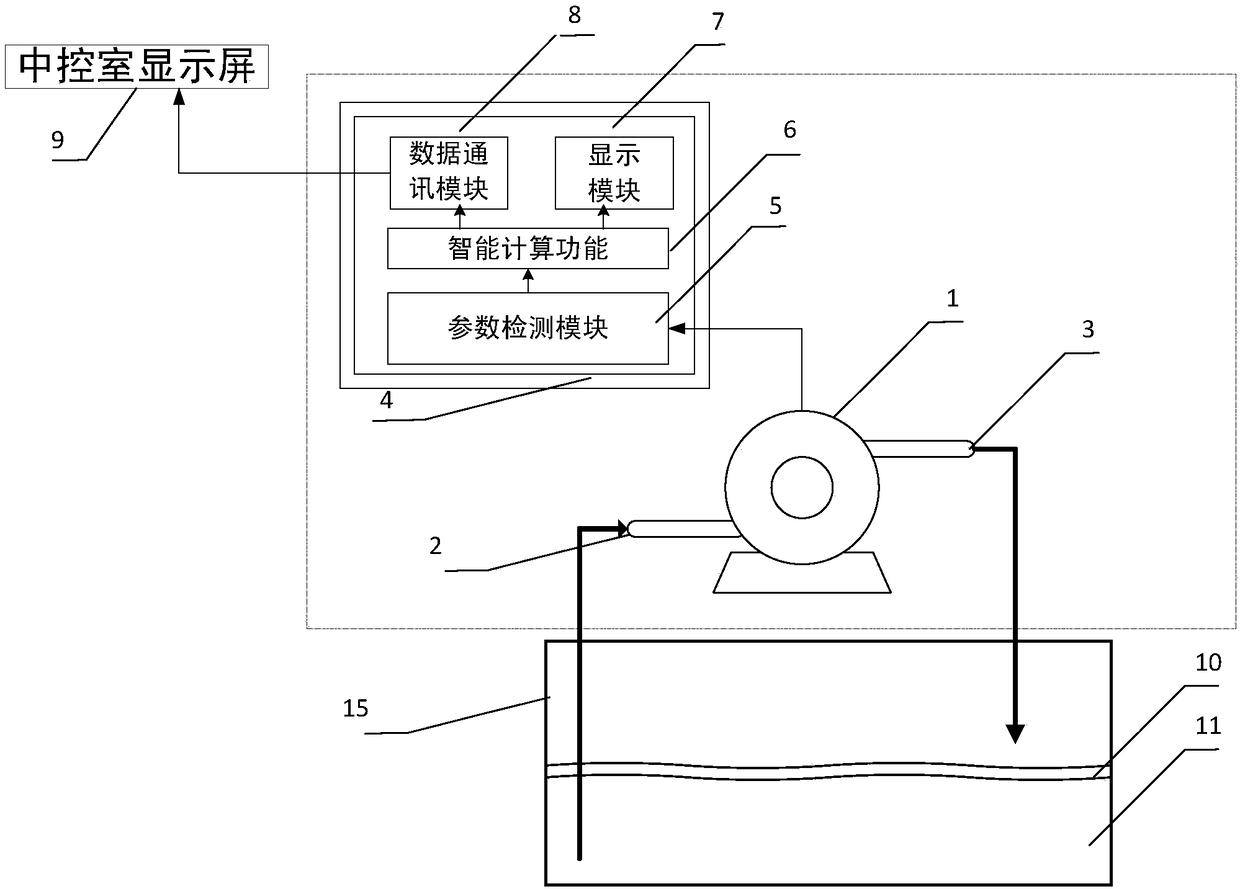

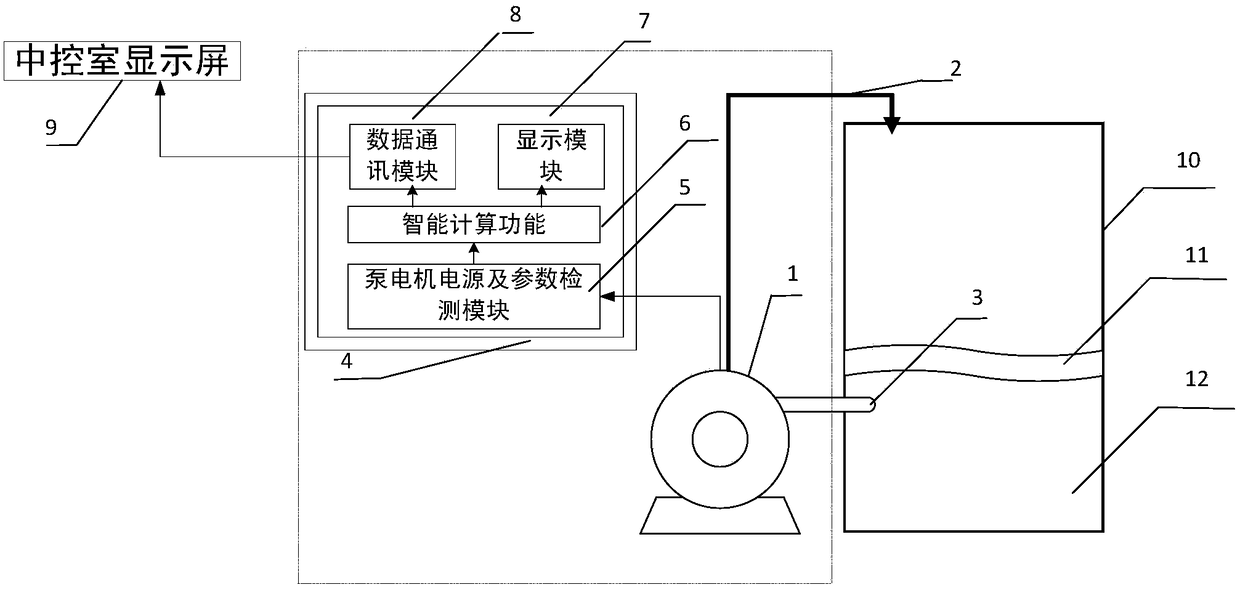

Embodiment 1

[0066] An online real-time detection device for pulp concentration, comprising a feed pipe (2), a discharge pipe (3), a sampling pump (1), an intelligent calculation module (6), a parameter detection module (5), a display module (7), The data communication module (8), the feed pipe (2) is made of seamless steel pipe, the discharge pipe (3) is made of seamless steel pipe, the sampling pump (1) is a SH1A-2S(R) slurry pump, and the intelligent calculation module ( 6) It is realized by CPUSR40 PLC. The parameter detection module (5) uses Siemens V20 inverter to supply power to the motor of the sampling pump (1) and detect the power of the motor of the sampling pump. The display module (7) adopts Siemens Smart1000IE industrial touch screen and data communication module (8) Siemens CSM1277 network switch is used. The container (15) where the pulp to be tested adopts a pulp tank, and the device adopts a tank type installation, and the installation method is as follows: figure 2 sho...

Embodiment 2

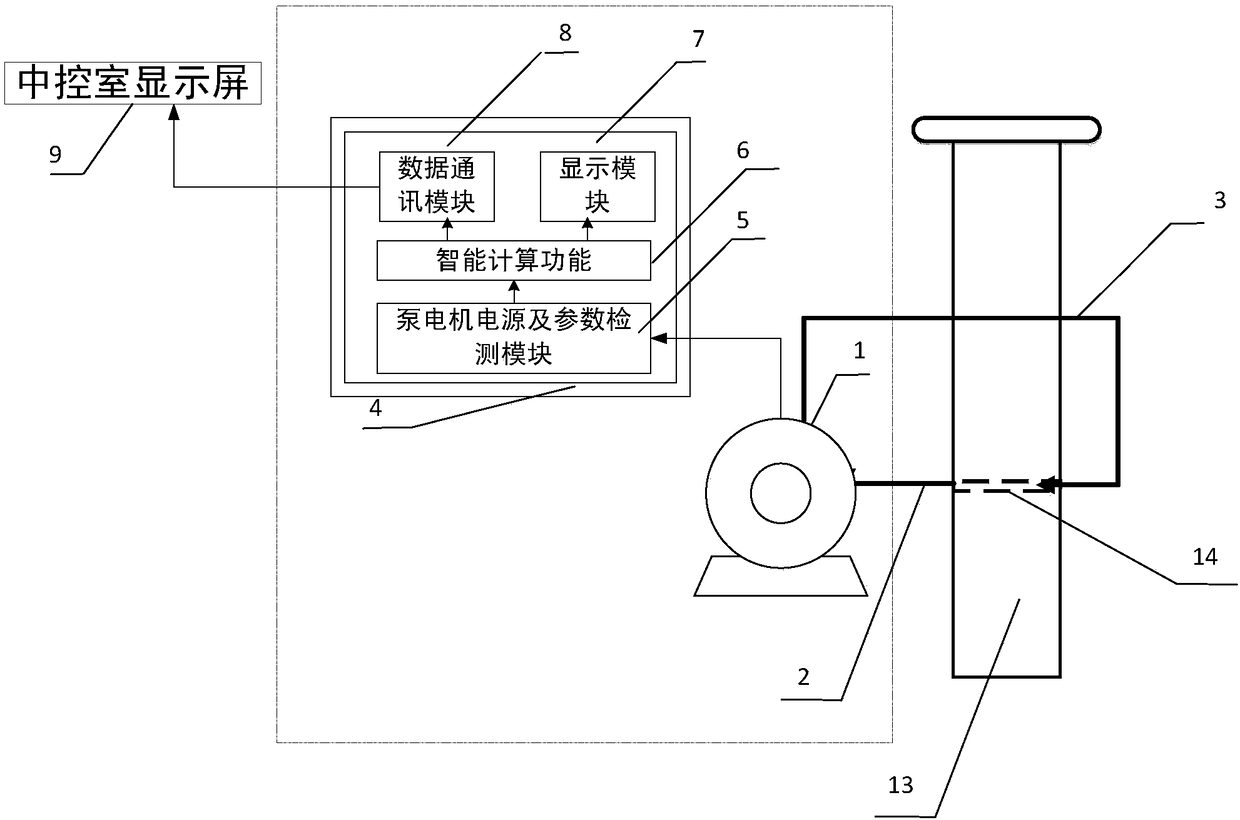

[0077]An online real-time detection device for pulp concentration, comprising a feed pipe (2), a discharge pipe (3), a sampling pump (1), an intelligent calculation module (6), a parameter detection module (5), a display module (7), The data communication module (8), the feed pipe (2) is made of seamless steel pipe, the discharge pipe (3) is made of seamless steel pipe, the sampling pump (1) is a SH1A-2S(R) slurry pump, and the intelligent calculation module ( 6) It is realized by a single-chip microcomputer. The parameter detection module (5) uses a 380V AC power supply to supply power to the sampling pump motor, and the BA05 type current transformer detects the current of the sampling pump motor. The display module (7) uses an 8-digit LED display, and the communication module (8) Ethernet gateway using microcontroller. Wherein, the container (15) where the pulp to be tested adopts a pulp pipeline, the device adopts a pipeline installation, and the method adopts a calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com