Large-cross section metal shielding flexible cable for mobile equipment

A technology of metal shielding and mobile equipment, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as cable insulation breakdown or leakage, cable twisting, cable conductor breakage, etc., to improve service life, improve extrusion resistance, Excellent anti-bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

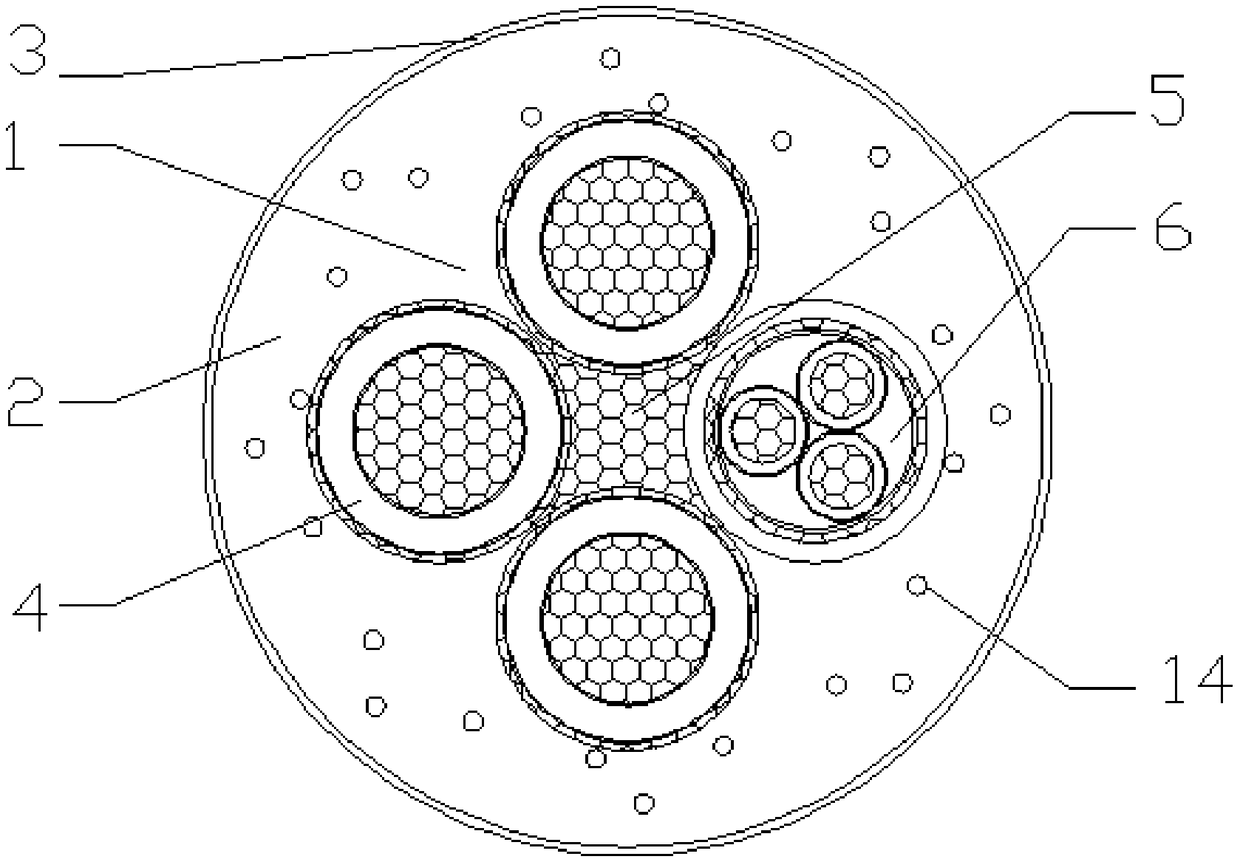

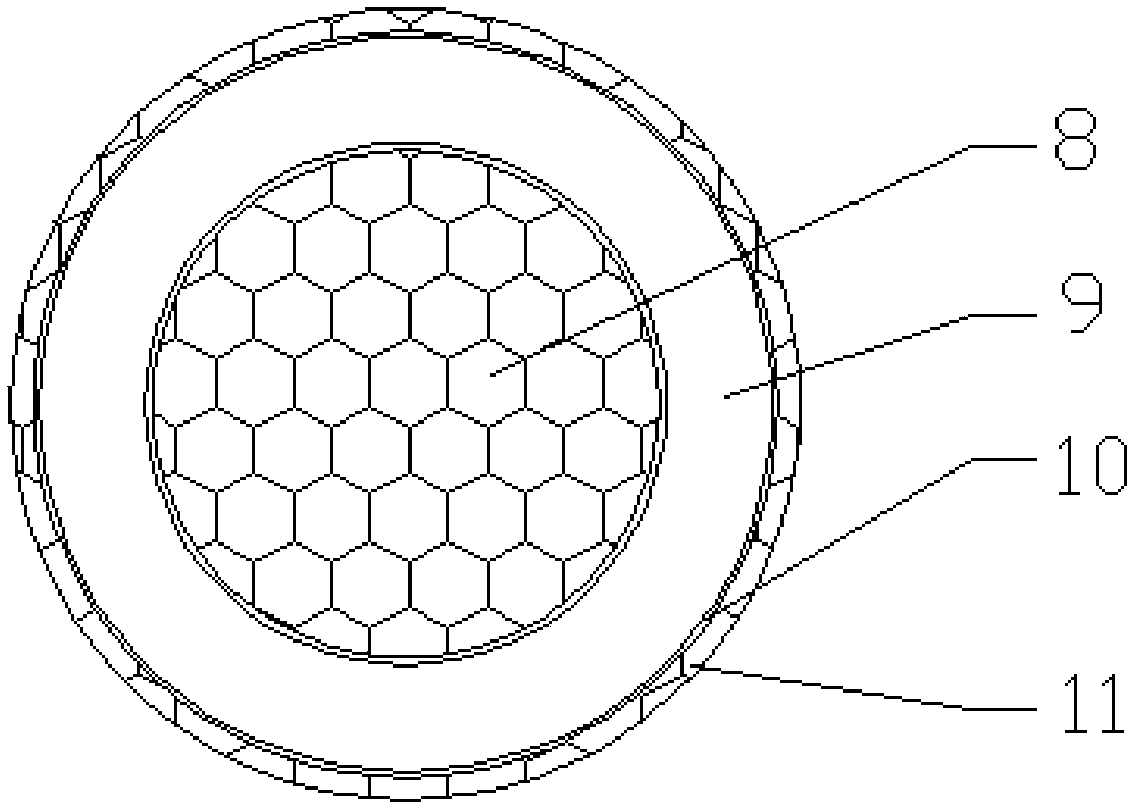

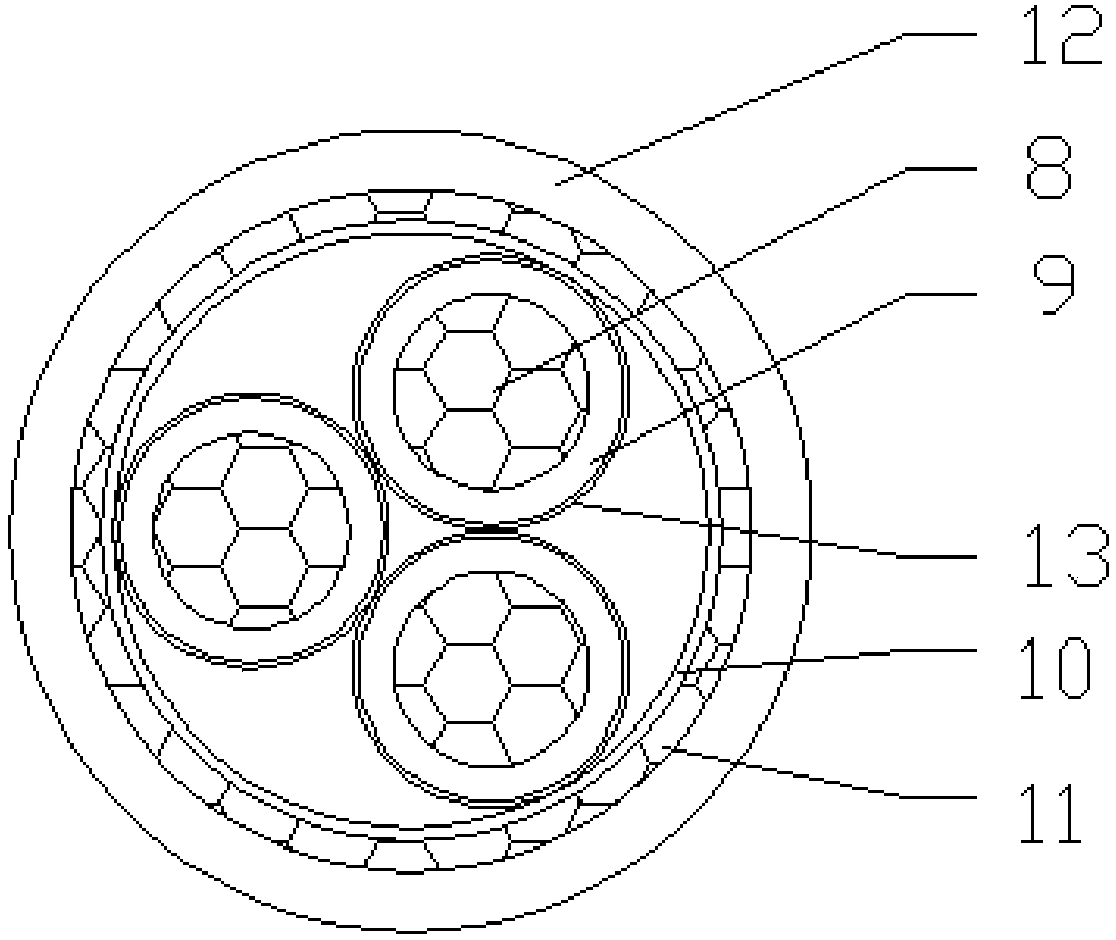

[0025] Such as Figures 1 to 3 Shown is a large cross-section metal shielded flexible cable for mobile equipment, the cable core is provided with a fiber braided reinforcement layer 1, an anti-twist sheath layer 2, and a wear-resistant layer 3 in sequence, and the cable core includes an insulating power Wire core group, deformable ground wire core 5 and control wire core group 6, wherein, the insulated power wire core group includes three power wire cores 4, and the power wire core 4 sequentially includes conductors 8, insulation Layer 9, isolation layer 10 and metal shielding layer 11, the deformable ground wire core 5 is twisted by tinned soft conductor, and the control wire core group 6 includes control cable core, isolation layer from inside to outside 10. Metal shielding layer 11 and sheath layer 12, the control cable core is formed by twisting three insulated cores, the power core 4 and the control core group 6 wrap the deformable ground core 5 And twisted to form the c...

Embodiment 2

[0034] The difference from the first embodiment above is that in this example, the set of insulated power cores includes five power cores, and the set of control cores includes four insulated cores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com