Double cooling for turbo motors

A dual cooling, turbine motor technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve problems such as thermal deviation, achieve smooth flow, improve cooling efficiency, and easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

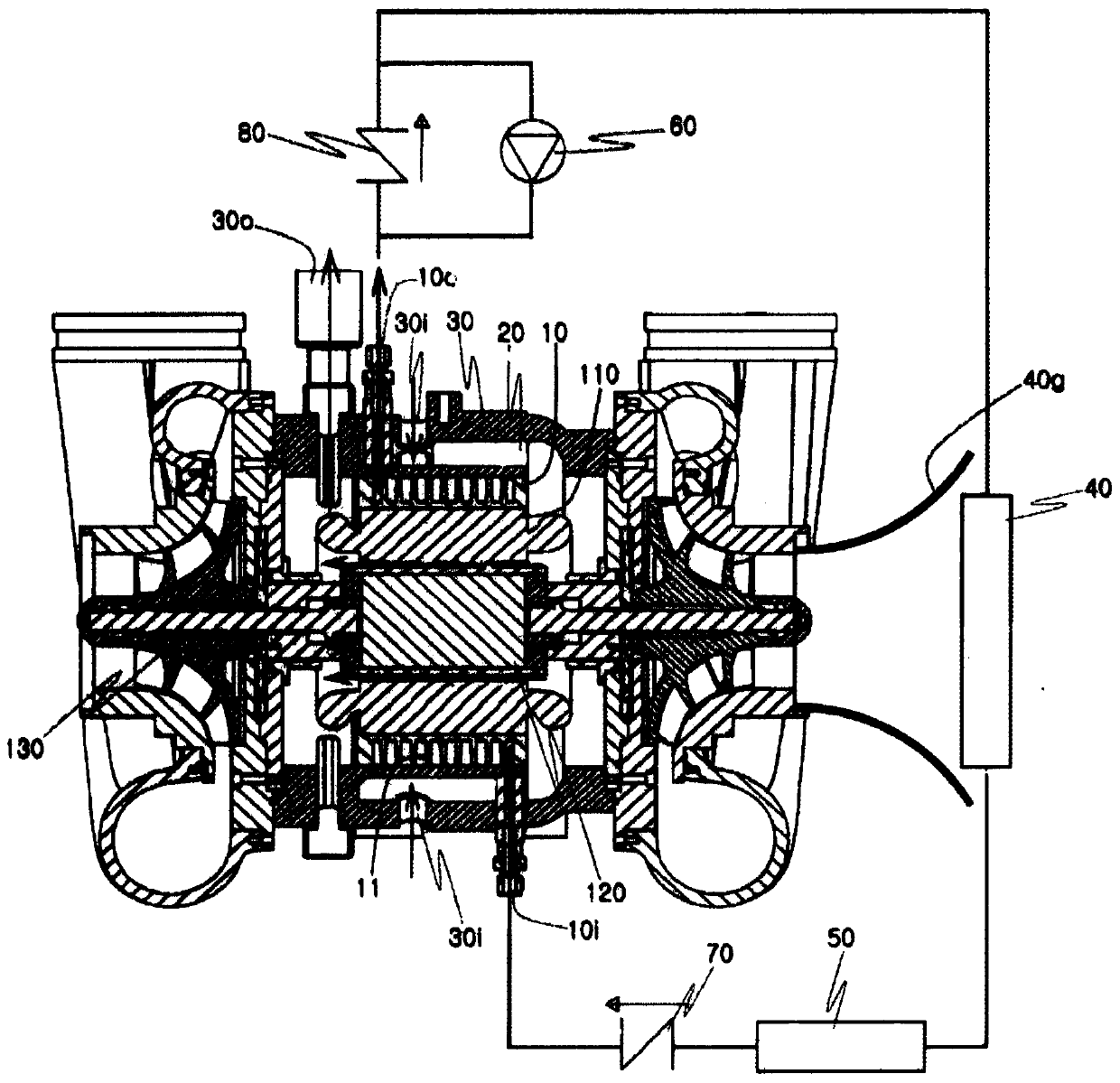

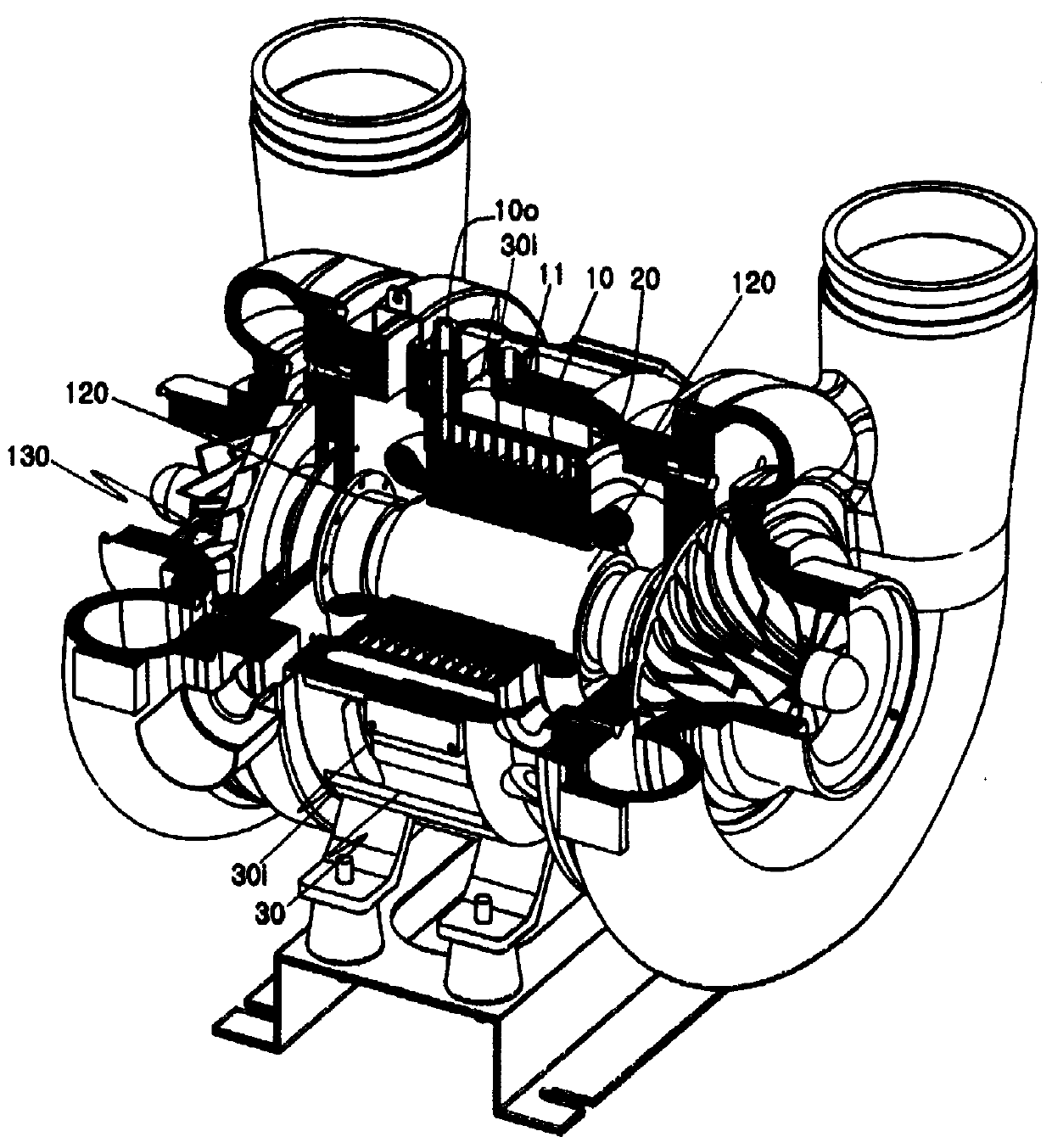

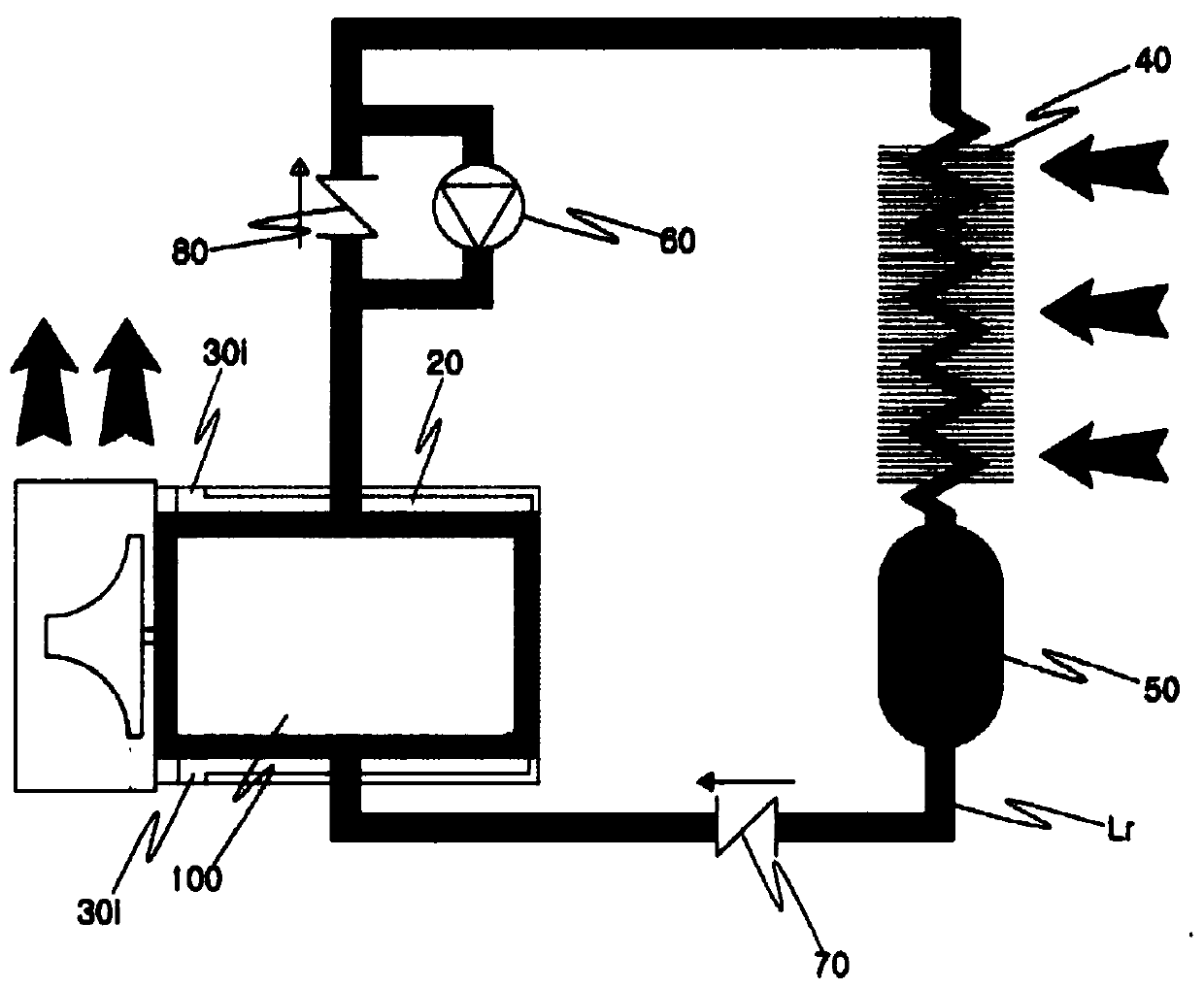

[0059] The following will describe in detail the dual cooling structure of the present invention which uses an air cooling structure and an internal circulating refrigerant to form a refrigeration cooling flow path for dual cooling and improved cooling efficiency of the motor. In the present invention, the high-output turbo blower utilizes the dual cooling structure of the turbo motor, which is composed of an air-cooled type and a refrigerated refrigerant circuit type, and improves cooling efficiency. Among them, an air flow path is formed between the rotor and the stator, and the motor is cooled by air, and a refrigerant circuit is provided outside the stator to form cooling, which improves the cooling efficiency of the double cooling structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com