Making method of coarse cereal thin pancakes

A technology for making pancakes and miscellaneous grains, which is applied in the direction of dough/premix, baking, baking mixture, etc. It can solve the problems of high food safety risk and low nutritional level, and achieve a full crispy feeling, improved nutritional value, and fine structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

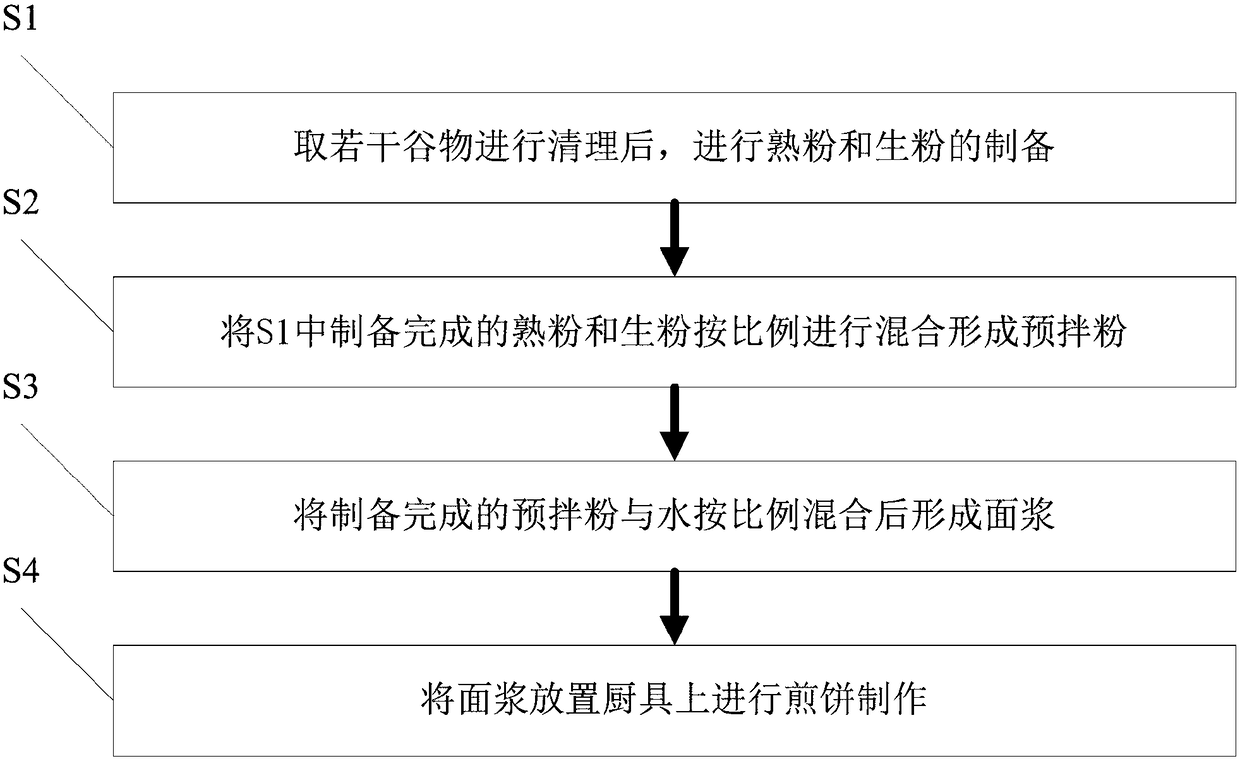

Method used

Image

Examples

Embodiment 1

[0049] Preparation of cooked flour: take 30g of corn, 20g of wheat, 10g of millet, 10g of buckwheat, 10g of sorghum, 10g of mung bean and 10g of oats, clean and dry them, put them into a twin-screw extruder for cooking, and ensure that the temperature is 110°C, the screw speed is 200rpm, and the cooked shaft passes through a 60-mesh sieve for later use;

[0050] Raw flour preparation: take corn, wheat, millet, buckwheat, sorghum, mung beans and oats, clean and dry them separately, and grind the dried corn, wheat, millet, buckwheat, sorghum, mung beans and oats, and grind them After the powder is passed through a 60-mesh sieve, mix according to the ratio of 30g corn, 20g wheat, 10g millet, 10g buckwheat, 10g sorghum, 10g mung bean and 10g oat;

[0051] Preparation of ready-mixed powder: Take 40g of cooked powder and 60g of raw powder, mix them, and add 500mL of water after mixing to form batter;

[0052] Pancake making: put the batter on the pan for pancake making, and the prepa...

Embodiment 2

[0054] Preparation of cooked flour: take 300g of corn, 200g of wheat, 100g of millet, 100g of buckwheat, 100g of sorghum, 100g of mung bean and 100g of oats, clean and dry them, put them into a twin-screw extruder for cooking, and ensure that the temperature is 120°C, the screw speed is 300rpm, and the cooked shaft passes through a 60-mesh sieve for later use;

[0055] Raw flour preparation: take corn, wheat, millet, buckwheat, sorghum, mung beans and oats, clean and dry them separately, and grind the dried corn, wheat, millet, buckwheat, sorghum, mung beans and oats, and grind them After the powder is passed through a 60-mesh sieve, 300g of corn, 200g of wheat, 100g of millet, 100g of buckwheat, 100g of sorghum, 100g of mung bean and 100g of oat are mixed according to the ratio;

[0056] Preparation of ready-mixed powder: Take 500g of cooked powder and 500g of raw powder, mix them, and add 5000mL of water after mixing to form batter;

[0057] Pancake making: put the batter o...

Embodiment 4

[0059] Preparation of cooked flour: Take 3kg of corn, 2kg of wheat, 1kg of millet, 1kg of buckwheat, 1kg of sorghum, 1kg of mung bean and 1kg of oats, clean and dry them, put them into a twin-screw extruder for cooking, and ensure that the temperature during the cooking process is 140°C, the screw speed is 350rpm, and the cooked shaft passes through a 60-mesh sieve for later use;

[0060] Raw flour preparation: take corn, wheat, millet, buckwheat, sorghum, mung beans and oats, clean and dry them separately, and grind the dried corn, wheat, millet, buckwheat, sorghum, mung beans and oats, and grind them After powdering, pass through a 60-mesh sieve respectively, and mix according to the ratio of taking 3kg of corn, 2kg of wheat, 1kg of millet, 1kg of buckwheat, 1kg of sorghum, 1kg of mung bean and 1kg of oat;

[0061] Preparation of ready-mix powder: Take 7kg of cooked flour and 3kg of raw flour, mix them, and add 50L of water to mix and stir to form noodle paste;

[0062] Pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com