Chain drive differential mechanism for independent suspension between wheels

A technology of independent suspension and differential mechanism, which is applied in the field of differential devices and chain transmission differential mechanisms, can solve the problems of high cost, difficult disassembly and maintenance, and immaturity, and meet the requirements of reducing the working angle and improving structural stability , the effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, how the patent of the present invention is implemented is further explained in conjunction with the accompanying drawings:

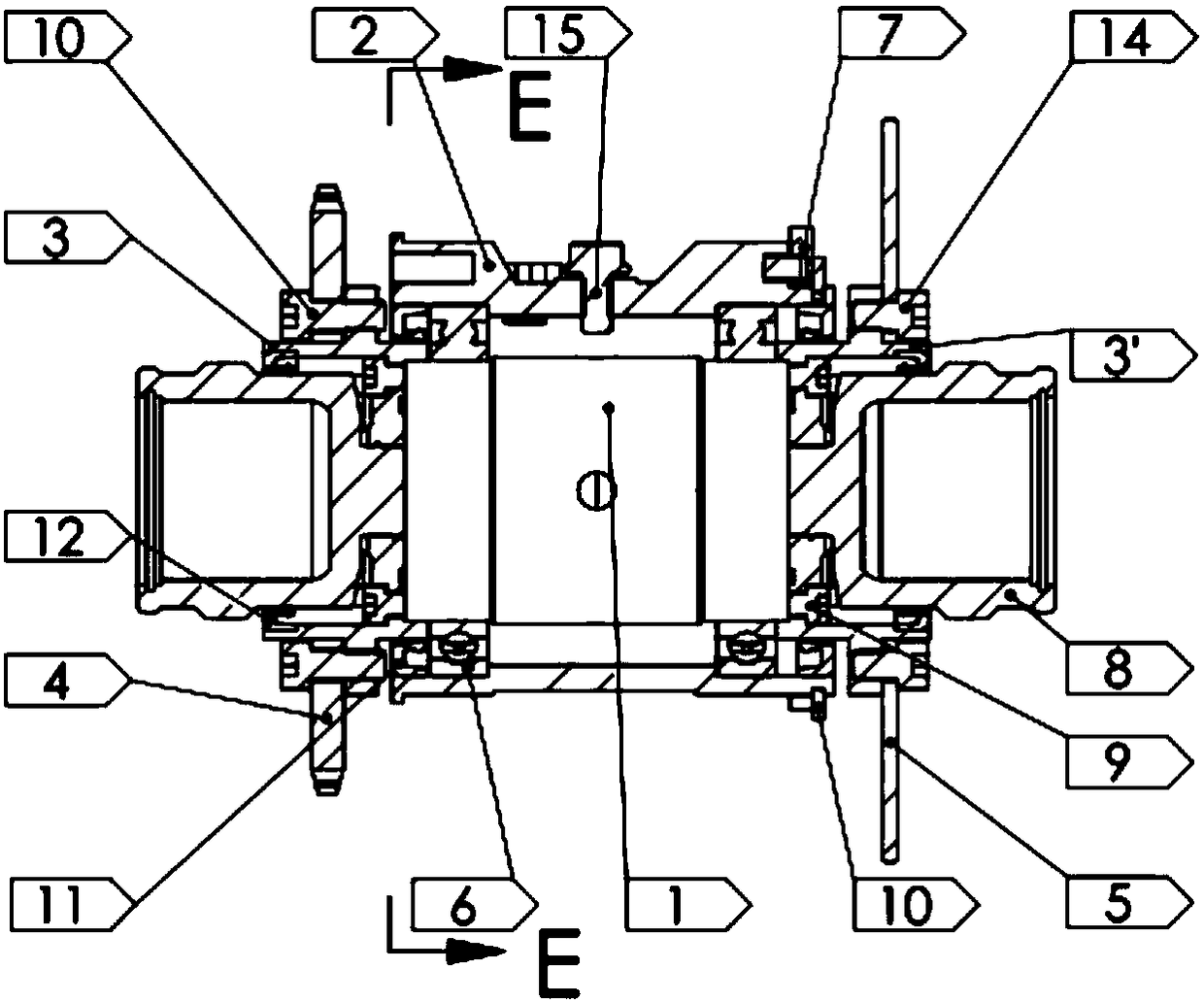

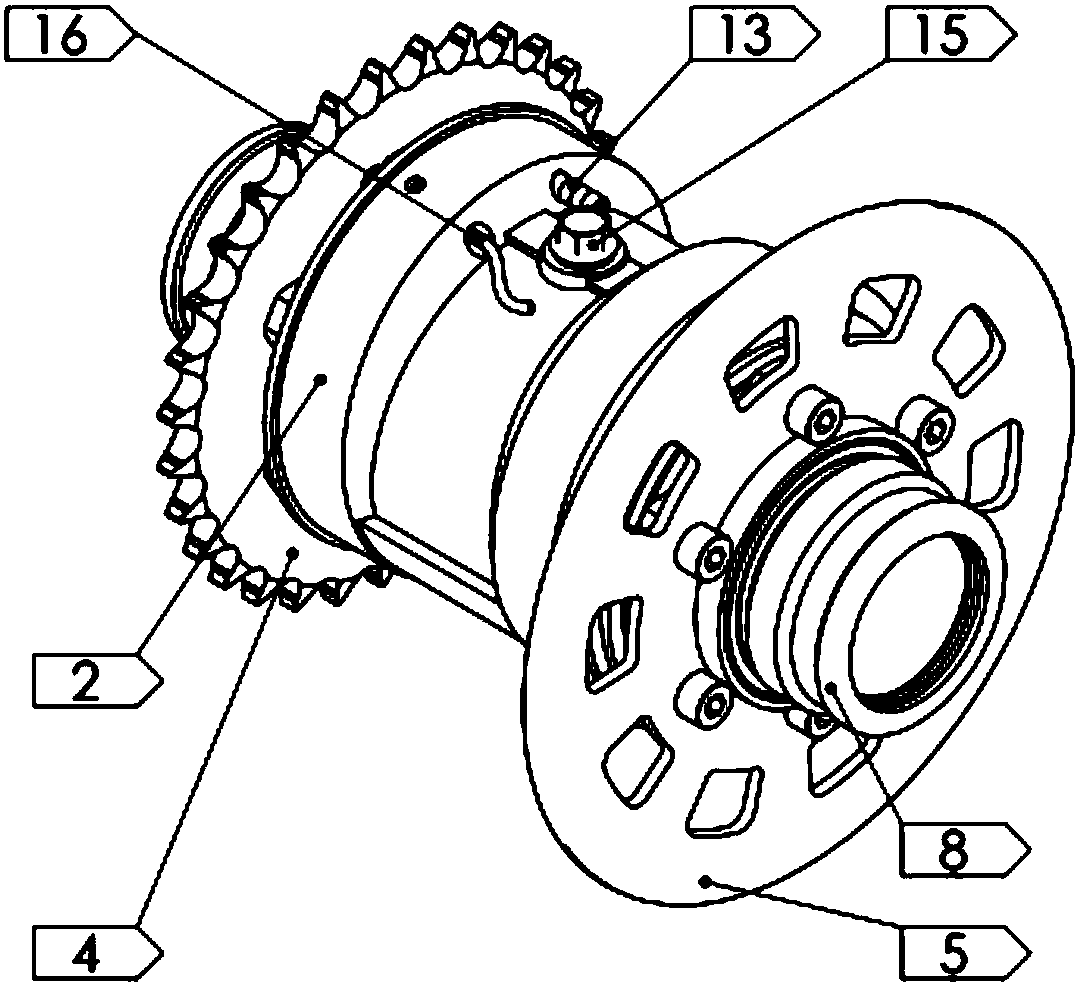

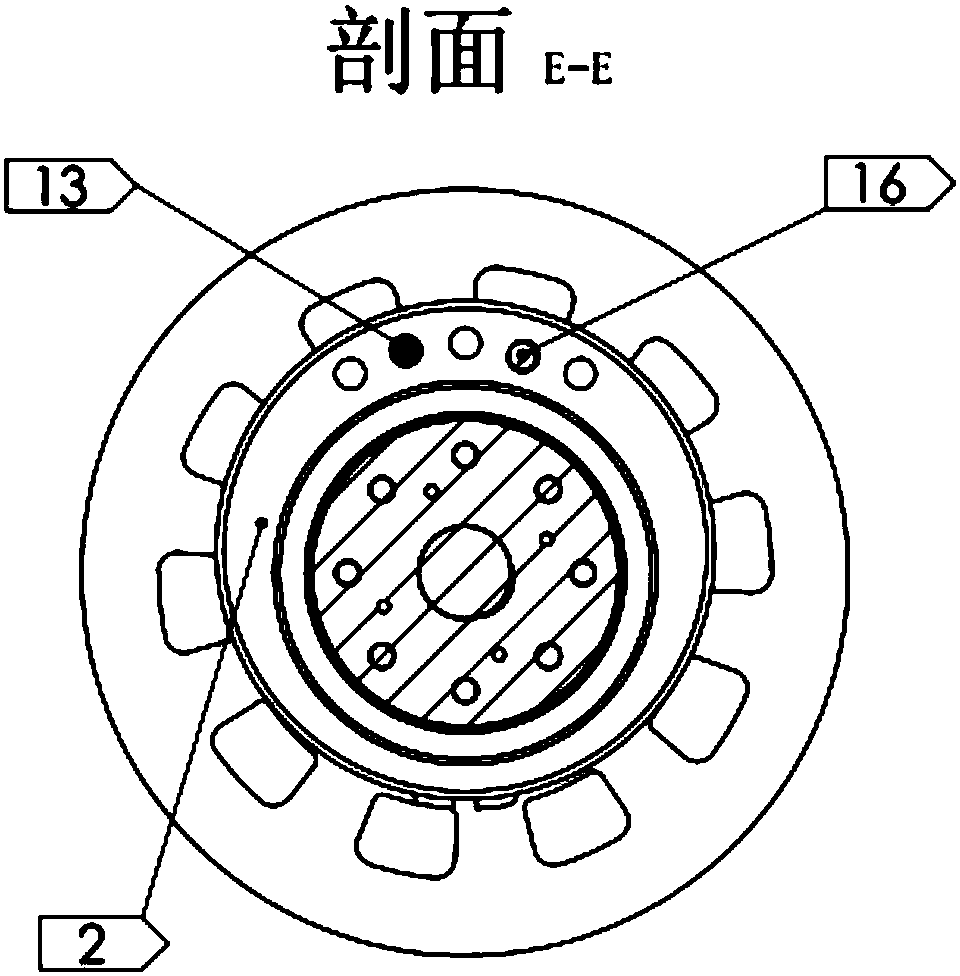

[0021] A chain transmission differential mechanism for independent suspension between wheels, such as figure 1 As shown, the differential 1 is installed in the eccentric sleeve 2 through the bearing 6, the left end cover 3 and the right end cover 3' are respectively connected with the differential 1 with bolts 9 to form a whole, and the sprocket disc 4 and the brake disc 5 are respectively used The bolt 14 device is fixed on the left end cover 3 and the right end cover 3', and the eccentric sleeve 2 can be placed in the rear flat fork 17 of the vehicle frame to rotate to adjust the chain tightness (this is to use the eccentric principle to change the large fly and small sprocket discs). Fly (little fly on the engine) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com