Storage-type full-automatic feeding and charging conveying system

A conveying system, fully automatic technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low degree of automation, poor effect, low efficiency, etc., and achieve the effect of solving low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

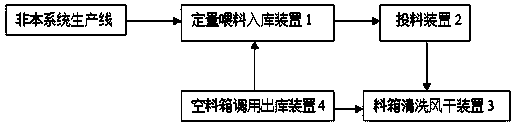

[0024] A warehouse-type automatic feeding and feeding conveying system, including a quantitative feeding storage device 1, a feeding device 2, a material box cleaning and air-drying device 3, and an empty material box calling and discharging device 4, and a chain conveyor is arranged between the four devices The chain conveyor belt is equipped with a rotary feeding shuttle car for transporting materials, a quantitative feeding storage device 1, a feeding device 2, a bin cleaning and drying device 3, an empty bin calling out storage device 4, and a rotary feeding shuttle The cars are connected to the external control system, which can solve the problems of low automation, low efficiency and poor effect in the production process of the food and pharmaceutical industries.

Embodiment 2

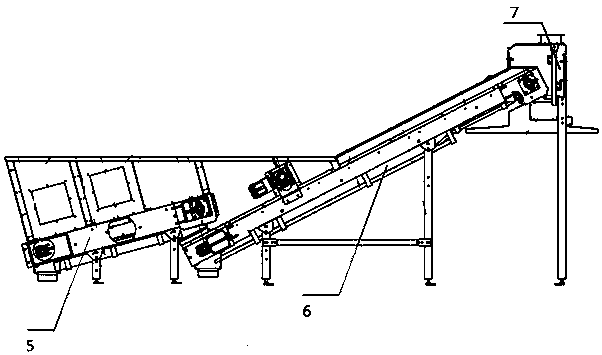

[0026] A warehouse-type automatic feeding and feeding conveying system, including a quantitative feeding storage device 1, a feeding device 2, a material box cleaning and air-drying device 3, and an empty material box calling and discharging device 4, and a chain conveyor is arranged between the four devices The chain conveyor belt is equipped with a rotary feeding shuttle car for transporting materials, a quantitative feeding storage device 1, a feeding device 2, a bin cleaning and drying device 3, an empty bin calling out storage device 4, and a rotary feeding shuttle The cars are all connected with the external control system, the quantitative feeding storage device 1 includes a feeder and a hoist, the feeder includes a chain belt conveyor 5, a lifting belt conveyor 6 and a blanking device 7, and a chain belt conveyor 5 and the lifting belt conveyor 6 are installed obliquely, the discharge end of the chain belt conveyor 5 is set on the upper part of the feeding end of the li...

Embodiment 3

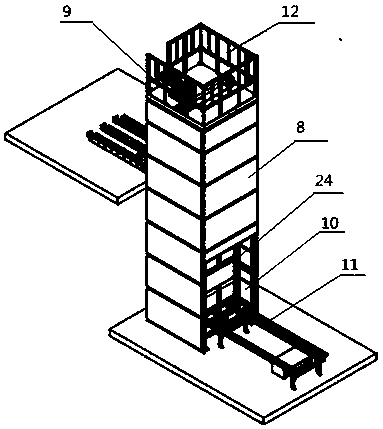

[0028] A warehouse-type automatic feeding and feeding conveying system, including a quantitative feeding storage device 1, a feeding device 2, a material box cleaning and air-drying device 3, and an empty material box calling and discharging device 4, and a chain conveyor is arranged between the four devices The chain conveyor belt is equipped with a rotary feeding shuttle car for transporting materials, a quantitative feeding storage device 1, a feeding device 2, a bin cleaning and drying device 3, an empty bin calling out storage device 4, and a rotary feeding shuttle The cars are all connected to the external control system. The hoist consists of a main frame 8, a transmission device 9, a lifting car 10 and a conveyor chain machine 11. The transmission device 9 is arranged on the top of the main frame 8, and the inner side of the main frame 8 is provided with a lifting guide rail 24. , the hoisting car 10 and the conveyor chain machine 11 are all arranged on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com