Special two-component solvent-free type polyurethane adhesive for high-barrier aluminium-plastic material and preparation method thereof

A polyurethane adhesive, two-component technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of low composite strength, high barrier aluminum-plastic materials do not have composite fastness, composite film A large number of bubbles and other problems, to achieve the effect of easy control of parameters and no emission during the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The special two-component solvent-free polyurethane adhesive for high barrier aluminum-plastic materials is composed of glue A and glue B. The specific preparation steps are as follows:

[0021] The first step, the preparation of glue A:

[0022] Take 350g of polyether polyol with a molecular weight of 1000-2000, 150g of TDI, 150g of IPDI and 100g of hexamethylene diisocyanate trimer in a four-necked flask, and react for 6 hours under the condition of raising the temperature to 80-90°C, and then raise the temperature Dehydrate at 100-120°C for 2 hours under the condition of vacuum degree of -0.1MPa, if the water content of the detection system is less than 0.05%, it is qualified, and the temperature is lowered to 40°C to obtain glue A.

[0023] The second step, the preparation of B glue:

[0024] Take 70g of dimer acid, 100g of polyol, 140g of 1,3-butanediol, 190g of sebacic acid, and 140g of isophthalic acid in a 1000mL four-necked flask, and add 0.1-0.25g of tetrabut...

Embodiment 2

[0030] The preparation process of the solvent-based two-component polyurethane adhesive is the same as in Example 1.

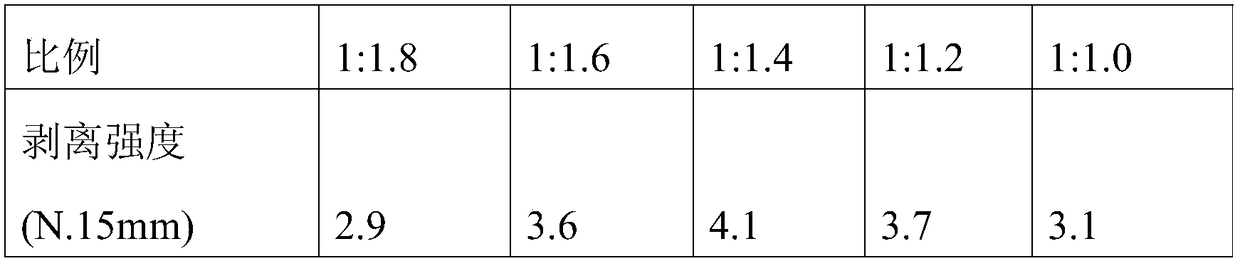

[0031] In order to examine the effect of the amount of polyol on the water boiling resistance of composite materials, the mass ratios of polyol and 1,3-butanediol were adjusted to 1:1.8, 1:1.6, 1:1.4, 1:1.2, 1:1, respectively. 1.0. Add the prepared solvent-free polyurethane adhesive to the gluing system of the solvent-free laminating machine, and the gluing amount is 2.0g / m 2 , using PET and PA as substrates to prepare aluminum-plastic composite materials. After further aging, the peel strength was tested according to the steps of GB / T2791-1995. The results are shown in Table 1. With the increase of the proportion of polyols, the peel strength It increases first, then decreases, and the peel strength reaches the highest when the molar ratio is 1:1.4. The reason for the increase in peel strength is that the increase in the proportion of polyols will increase ...

Embodiment 3

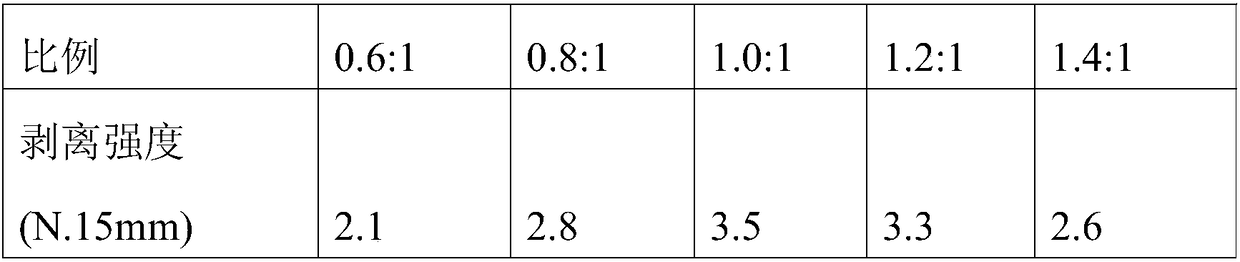

[0035] The preparation process of the solvent-based two-component polyurethane adhesive is the same as in Example 1.

[0036] Add the prepared solvent-free polyurethane adhesive to the gluing system of the solvent-free laminating machine, and the gluing amount is 2.0g / m 2 , with PET and PA as the base material, PET / PA, PET / PET and PA / PA composite materials were prepared respectively. After further curing, the peel strength was tested according to the steps of GB / T2791-1995. The results are shown in Table 3. It was found that This glue has good adhesion fastness to three kinds of aluminum-plastic composites.

[0037] table 3

[0038]

[0039] The solvent-type two-component polyurethane adhesive prepared by the present invention has good adhesion fastness to high-barrier aluminum-plastic materials, and the parameters of the preparation process are easy to control. The preparation process has no emissions, and belongs to the environment-friendly production scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com