Preparation method of tungsten diselenide nano-clathrate

A technology of tungsten diselenide and clathrate, which is used in lubricating compositions, petroleum industry, additives, etc., can solve the problems of large specific surface energy of nanoparticles, irritating odor and toxicity, and high product price, and achieve large specific surface area. , The parameters are easy to control, and the production process is safe and environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

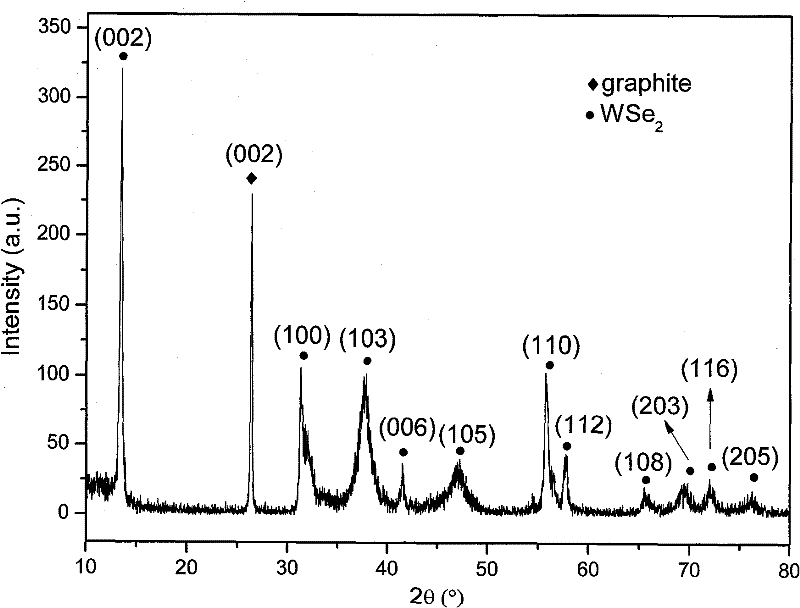

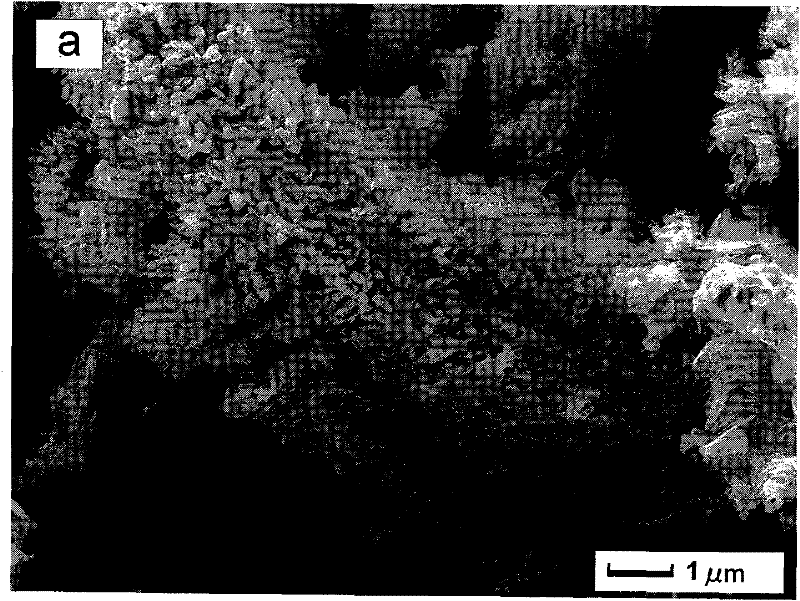

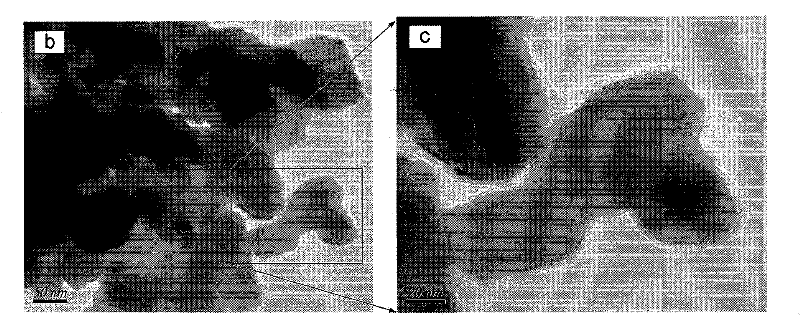

[0018] Prepare tungsten diselenide nano clathrate according to the following method:

[0019] (1) Preparation of raw material mixture: Weigh 1.0924g of tungsten powder, 1.1730g of selenium powder and 0.5462g of graphite powder (graphite), add them into a beaker filled with 10mL of absolute ethanol, and magnetically stir at room temperature for 30 minutes to obtain a raw material mixture;

[0020] (2) Pretreatment: place the above raw material mixture in a water bath at 100°C and continue stirring to evaporate absolute ethanol to obtain a paste;

[0021] (3) Solid-phase synthesis: transfer the above-mentioned paste to an oven at 80°C for 4 hours to dry, then transfer it to a stainless steel reaction kettle, seal it and place it in a tube furnace, and heat it up to 800°C at a rate of 10°C / min. ℃, after 2 hours of heat preservation, the room temperature is naturally cooled to obtain tungsten diselenide (WSe 2 ) nano clathrate.

[0022] Practice has proved that the preparation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com