Preparation method for sphere-like tungsten powder

A technology of near-spherical and tungsten powder, which is applied in the field of preparation of nearly-spherical tungsten powder, can solve the problems of difficult control of process parameters, long process route, and large waste liquid pollution, etc., and achieve simplified preparation process, easy control of parameters, and efficient treatment methods. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

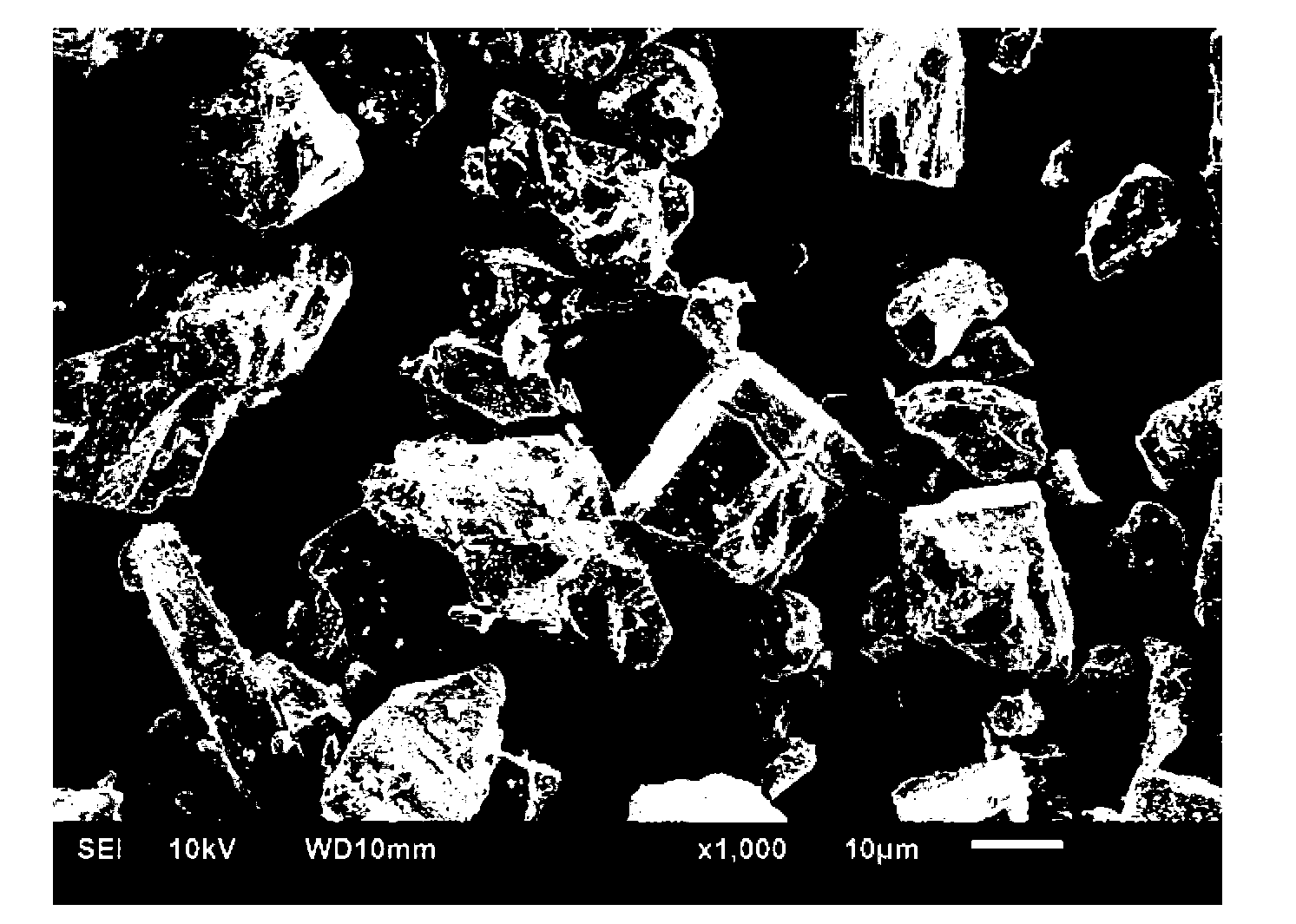

[0025] 1) Weigh a certain mass of tungsten oxide powder, then move the powder particles into the spheroidization equipment, and carry out spheroidization and shaping treatment on the tungsten powder under the conditions of a rotation speed of 3000r / min and a processing time of 60min;

[0026] 2) Sieving the tungsten oxide powder particles after the spheroidization treatment in step 1 to obtain a nearly spherical tungsten oxide powder with uniform particle size;

[0027] 3) Put the nearly spherical tungsten oxide powder in step 2 into a reduction furnace for reduction, the reduction temperature is 750°C, and the reduction time is 40 minutes. Prepared nearly spherical tungsten powder particles.

[0028]

Embodiment 2

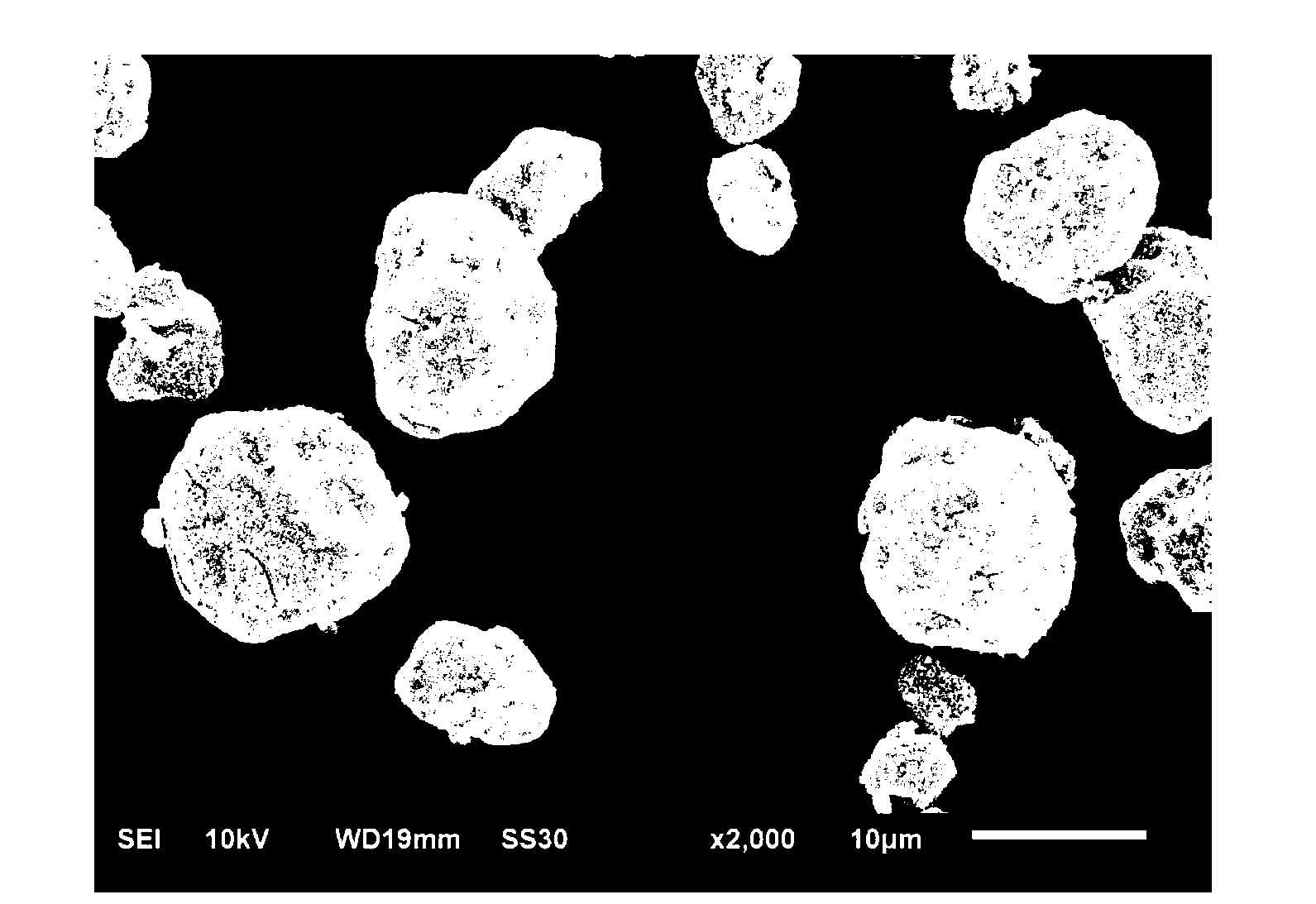

[0030] 1) Weigh a certain mass of tungsten oxide powder, then move the powder particles into the spheroidization equipment, and carry out spheroidization and shaping treatment on the tungsten powder under the conditions of the rotation speed of 3000r / min and the processing time of 30min;

[0031] 2) Sieving the tungsten oxide powder particles after the spheroidization treatment in step 1 to obtain a nearly spherical tungsten oxide powder with uniform particle size;

[0032] 3) Put the nearly spherical tungsten oxide powder in step 2 into a reduction furnace for reduction, the reduction temperature is 700°C, and the reduction time is 120 minutes. The near-spherical tungsten powder particles with uniform particle size are obtained.

[0033]

Embodiment 3

[0035] 1) Weigh a certain mass of tungsten oxide powder, then move the powder particles into the spheroidization equipment, and carry out spheroidization and shaping treatment on the tungsten powder under the condition of the rotation speed of 4000r / min and the processing time of 15min;

[0036] 2) Sieving the tungsten oxide powder particles after the spheroidization treatment in step 1 to obtain a nearly spherical tungsten oxide powder with uniform particle size;

[0037] 3) Put the nearly spherical tungsten oxide powder in step 2 into a reduction furnace for reduction, the reduction temperature is 750°C, and the reduction time is 60 minutes. The near-spherical tungsten powder particles with uniform particle size are obtained.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com