A two-dimensional configuration of multi-plate ejector and its application

A two-dimensional configuration and ejector technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve the problem of large flow loss of the ejected airflow, complex nozzle layout, affecting ejection performance, etc. problem, to achieve the effect of rapid hybrid development process, superior performance and low operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

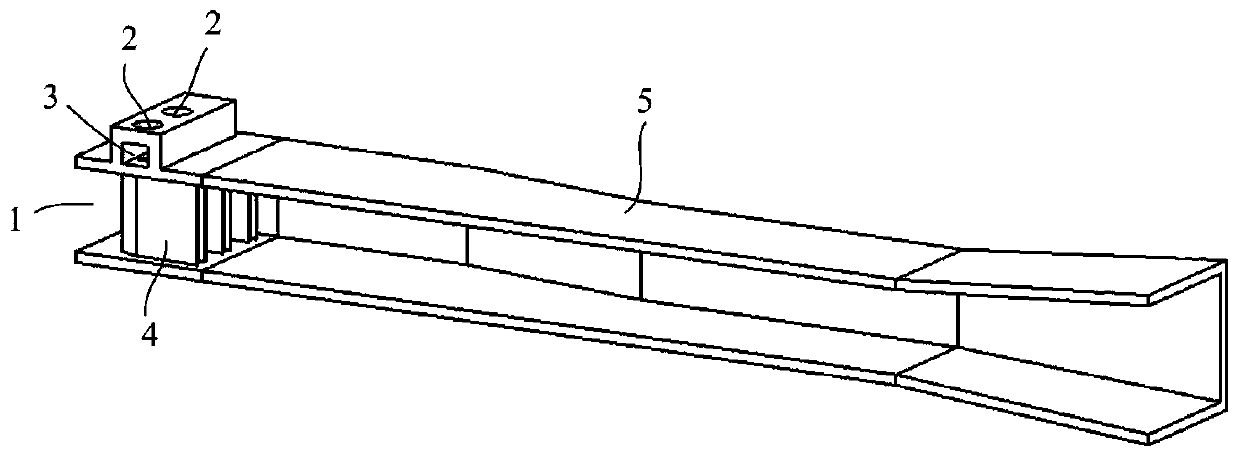

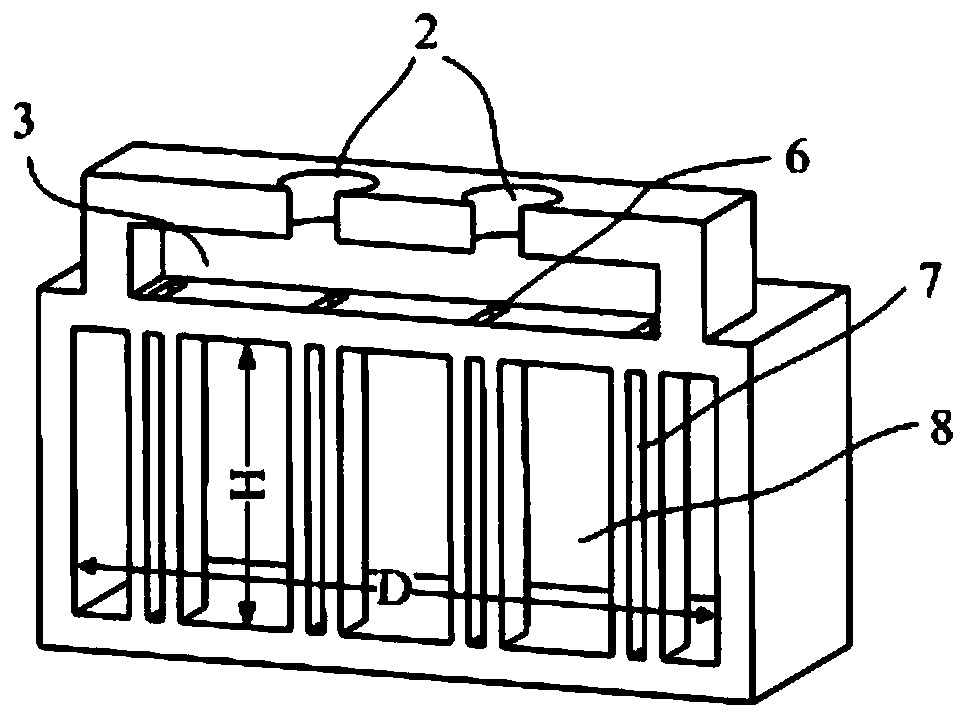

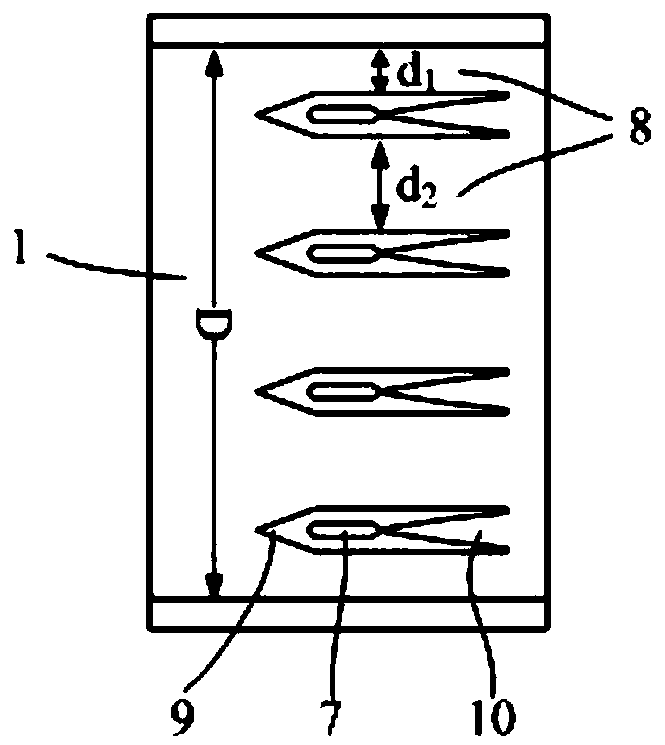

[0033]As shown in the accompanying drawings, the present invention proposes a multi-branch ejector with two-dimensional configuration. The opening at one end of the ejector is provided with an ejected air inlet 1 docked with the inner cavity of the ejector, and the shape and size of the ejected air inlet 1 are the same as the size of the inner rectangular cavity of the ejector. The opening at the other end is provided with a mixing diffuser pipe 5 that is docked with the inner cavity of the ejector, and a rectangular gas collection chamber 3 is provided on the upper side wall of the ejector, and the inner cavity of the ejector is provided with two Vertical support plate 4, the inside of the support plate 4 is provided with a vertical nozzle air guide cavity 7, the two ends of the support plate 4 are connected with the inner side wall of the ejector, on the side wall above the gas collection chamber 3 There is an ejection air inlet 2, and the gas collection chamber 3 and the no...

Embodiment 2

[0036] As shown in the accompanying drawings, the present invention proposes a multi-branch ejector with two-dimensional configuration. One end of the ejector is provided with an ejected air inlet 1 docked with the inner cavity of the ejector, and the shape and size of the ejected air inlet 2 is the same as the size of the inner rectangular cavity of the ejector, and the other end of the ejector is provided with There is a mixing diffuser pipe 5 docked with the inner cavity of the ejector, the shape and size of the end of the mixed diffuser pipe 5 docked with the ejector is the same as the size of the inner rectangular cavity of the ejector, and the upper side wall of the ejector and the lower side wall are respectively provided with a gas collection cavity 3, the inner cavity of the ejector is provided with four support plates 4, and the inside of the support plate 4 is provided with a vertical nozzle air guide cavity 7, above the ejector The upper side wall of the gas collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com