Water circulating system capable of preventing medium-frequency furnace equipment from being dewed

An intermediate frequency furnace and water circulation technology, which is applied in the field of water circulation system, can solve problems such as insulation resistance reduction, rust on conductive metal surfaces, and corroded circuits, and achieve the effects of preventing condensation, reducing aging, and stabilizing the inlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

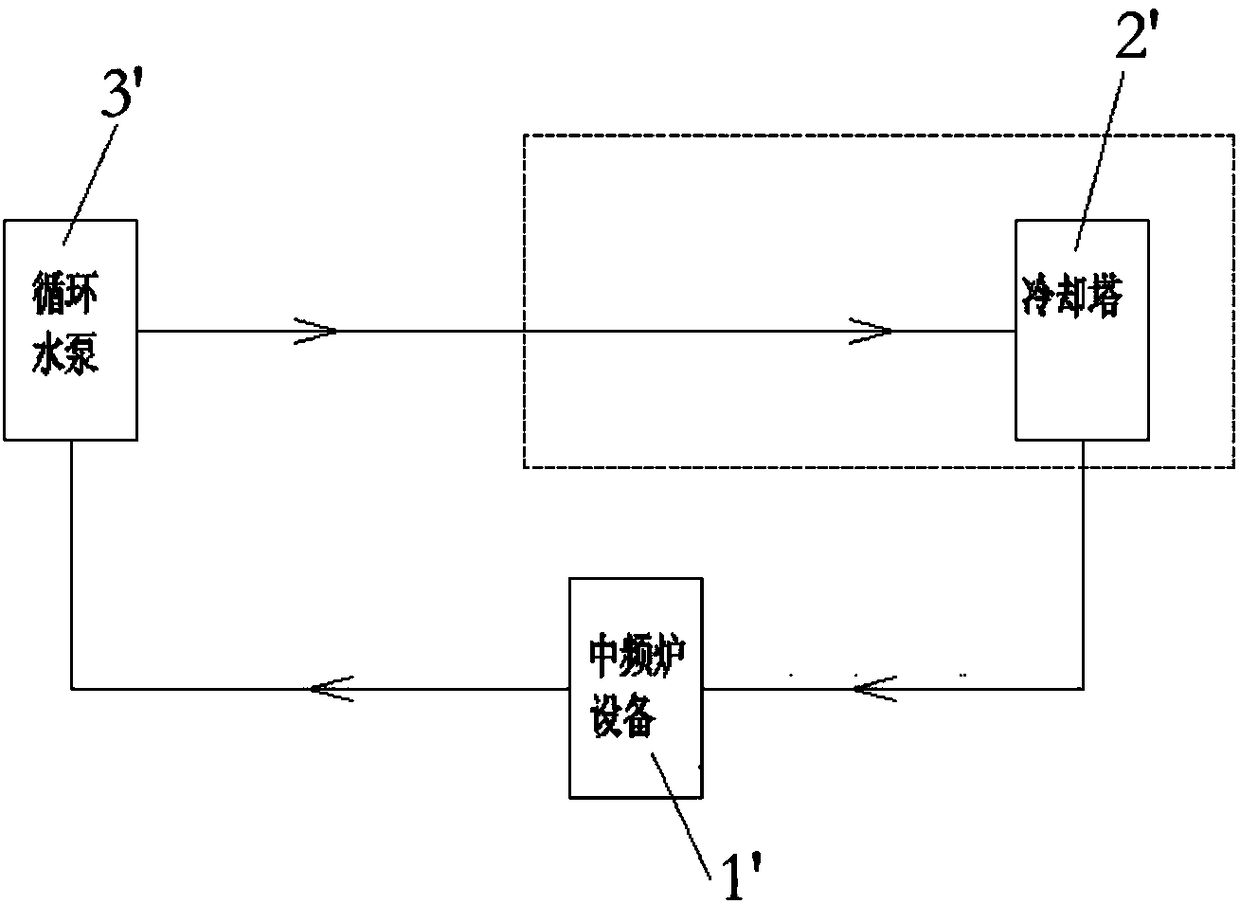

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

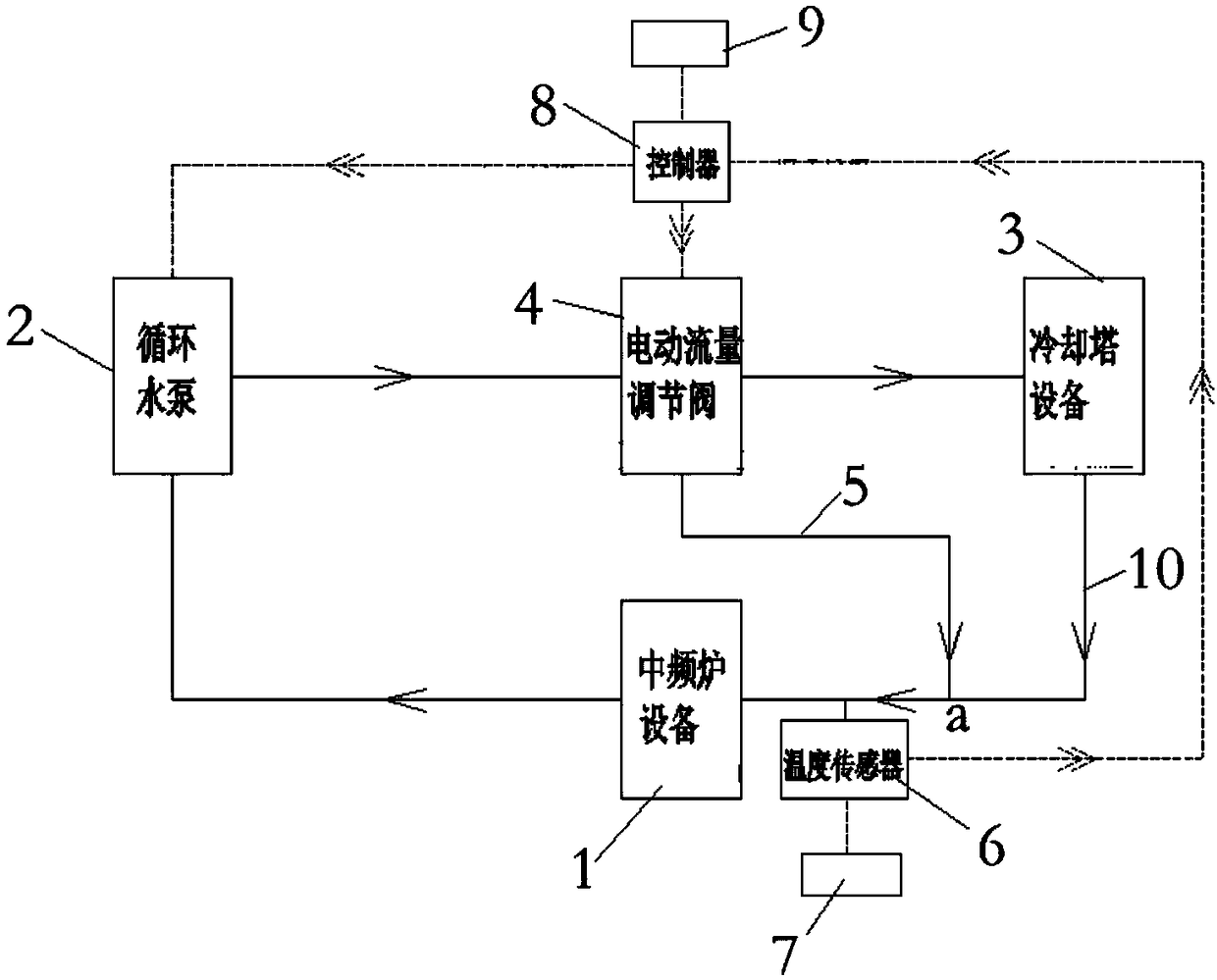

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0031] see figure 2 , the best embodiment of the present invention, a water circulation system for preventing condensation of intermediate frequency furnace equipment, including frequency conversion circulating water pump 2, electric flow regulating valve 4, cooling tower equipment 3, intermediate frequency furnace equipment 1, bypass pipe 5, temperature sensor 6. Temperature display 7, controller 8 and keyboard digital debugging module 9.

[0032] The outlet of the frequency conversion circulating water pump 2, the electric flow regulating valve 4, the cooling tower equipment 3, the intermediate frequency furnace equipment 1 and the inlet of the frequency conversion circulating water pump 2 are sequentially connected through pipelines; one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com