Generator stator end part winding structure optimization method based on particle swarm algorithm and support vector machine

A technology of support vector machines and generator stators, applied in design optimization/simulation, calculation, calculation model, etc., can solve the problems of increased time cost, complex finite element, long time consumption, etc., to reduce optimization time and improve optimization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

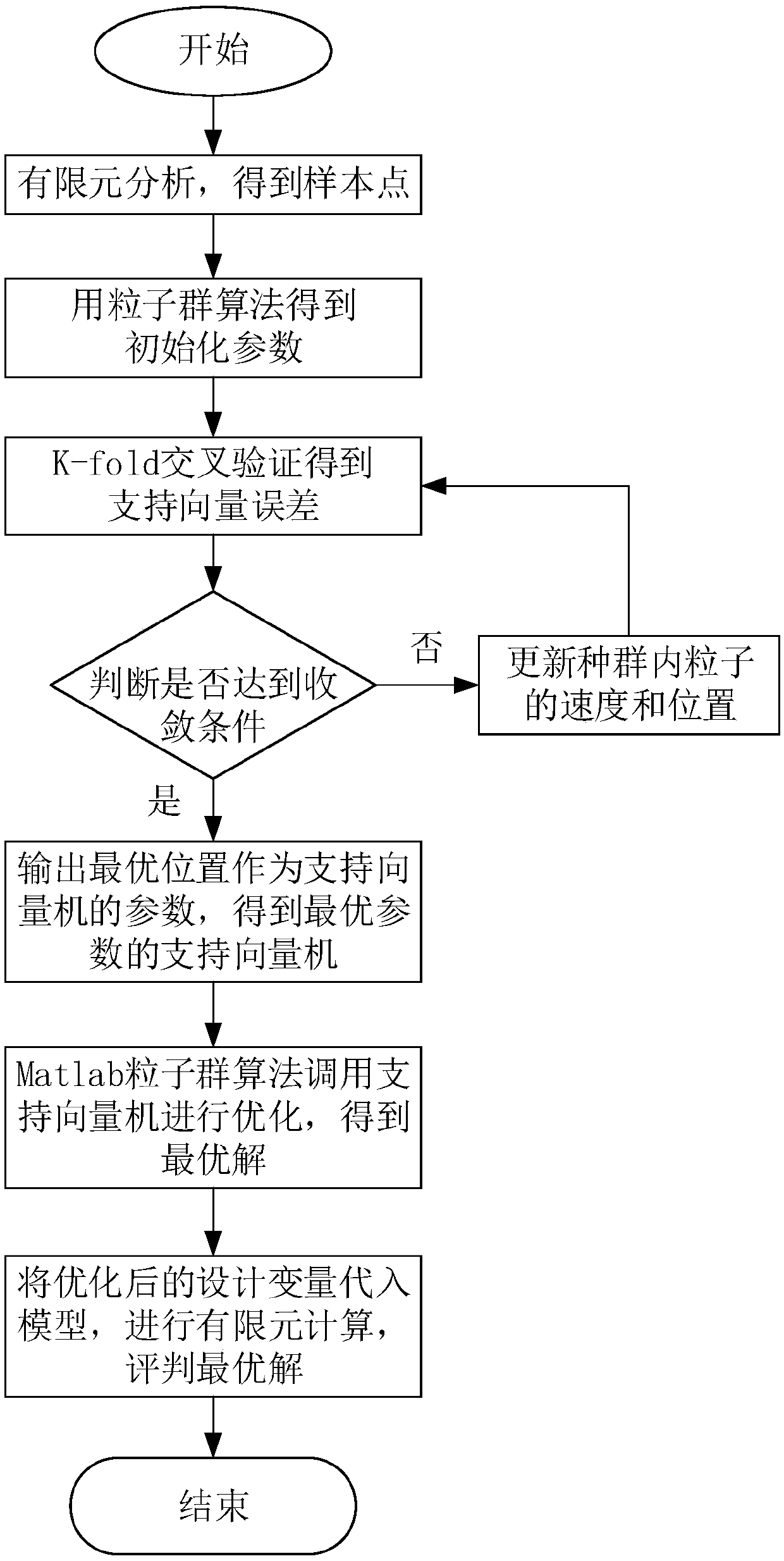

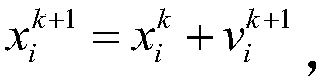

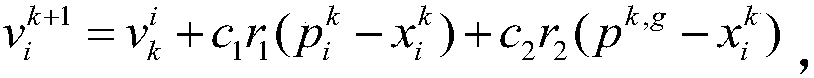

[0018] Conception of the present invention: carry out finite element analysis, record the design variables and structural responses of each analysis, and use them as input variables and output variable values respectively to obtain the sample points required for establishing a support vector machine approximation model, and use the obtained sample points to perform SVM Parameter selection, establish a support vector machine approximation model with optimal parameters to predict the structural response, then use PSO as the optimization algorithm, combine the support vector machine approximation model for optimization, obtain the optimal solution of the approximation model, and finally obtain the optimal design variable The value is substituted into the approximate model of the support vector machine to call the finite element program for calculation, and the calculation result is compared with the precise calculation result of the finite element to judge the optimal solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com