Electrically-driven hedge clipping device and method

A hedge trimming and electric drive technology, applied in the field of hedge trimming, can solve the problems of multiple labor resources, low hedge speed and accuracy, long trimming cycle, etc., and achieve the effect of simple implementation method steps, reliable hedge trimming, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

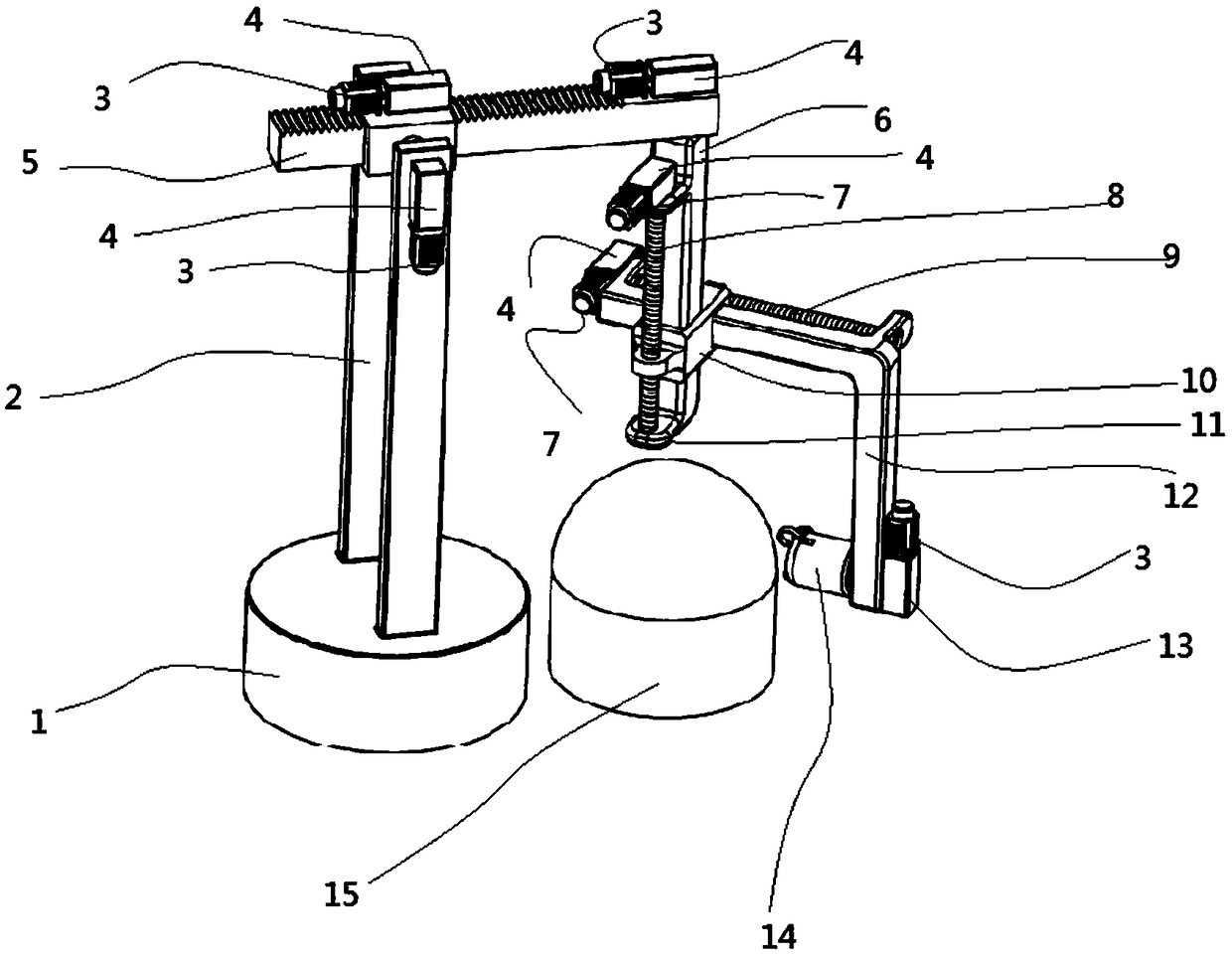

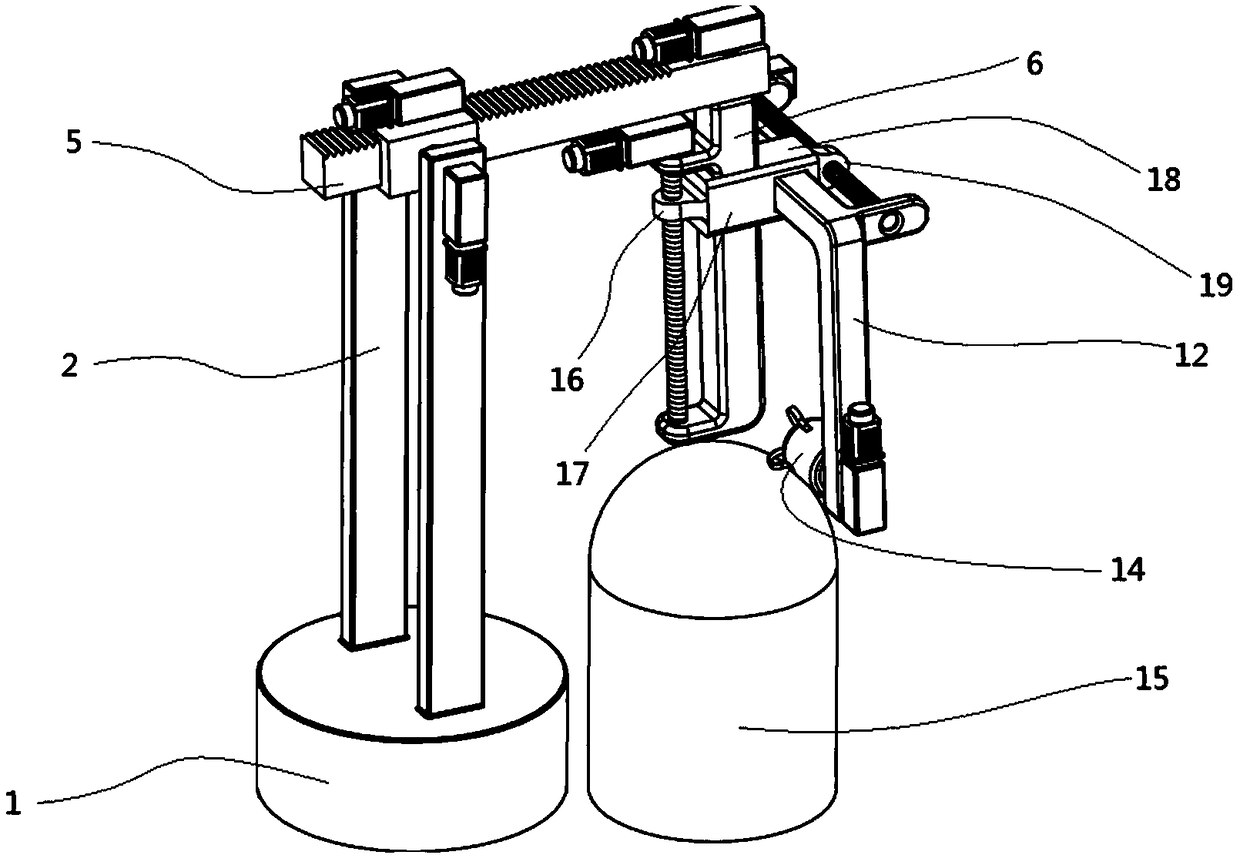

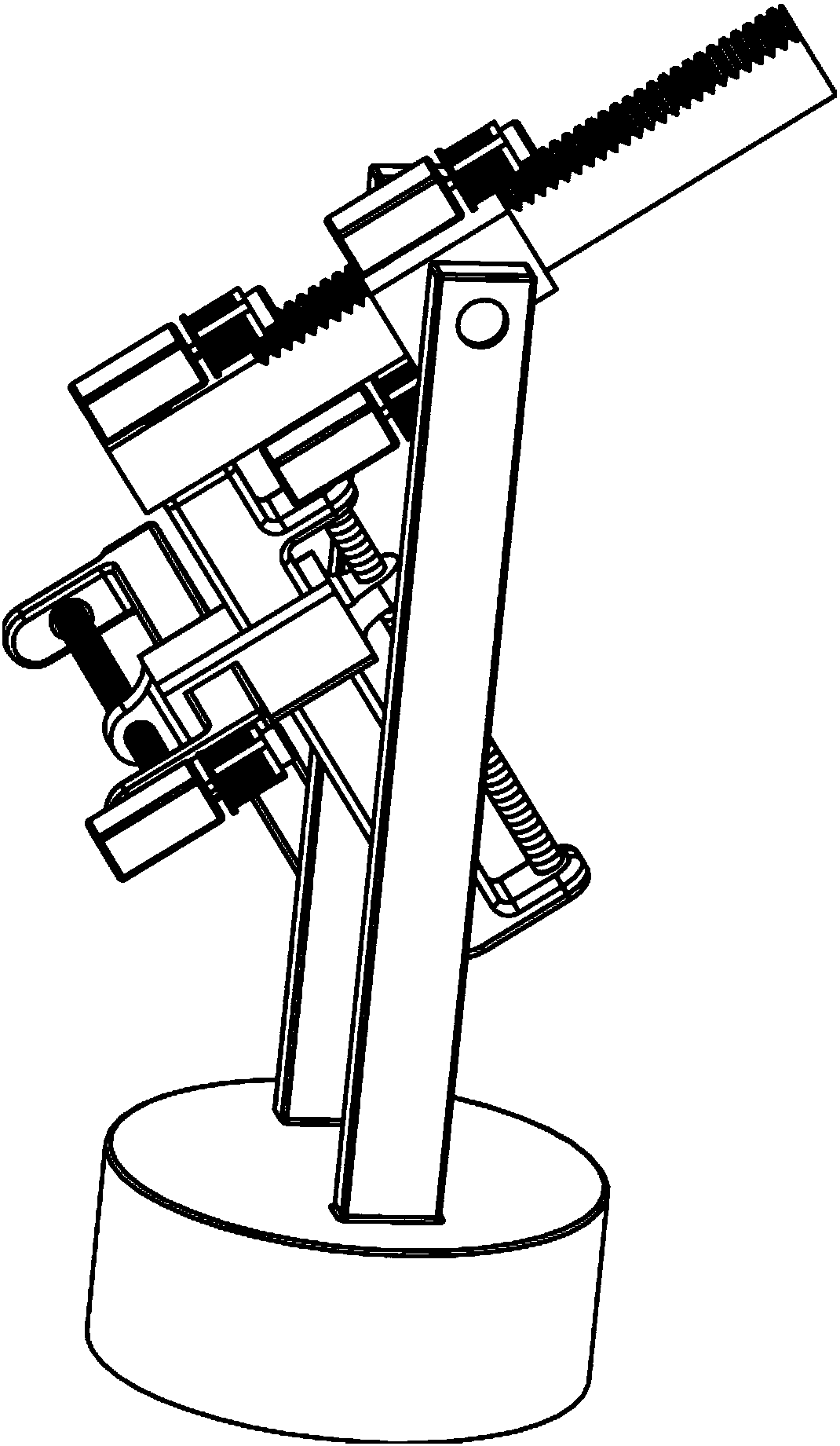

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] An electric-driven hedge trimming device, which includes a lifting system, a translation system, an overall rotation system, a tool rotation system, a trimming system, and a control system. The linkage of the system manipulates the trajectory of the tool to trim the desired hedge shape.

[0036] The overall rotation system is used to rotate the overall device to realize the large-angle rotation of the overall device, and the purpose is to facilitate the recovery and transportation of the overall device. The overall rotation system includes a rotating chassis, support beams, telescopic beams, motors, and reducers. The rotating chassis is used to place the entire device on the ground or on a platform. Two supporting beams are symmetrically installed on the rotating chassis. The telescopic beam is installed on the upper part of the supporting beam throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com