Allium mongolium regel dietary fiber soda biscuit and production process thereof

A soda biscuit and dietary fiber technology, applied in food science, baked food with modified ingredients, baking, etc., can solve the problem of low calorie, and achieve the effect of simple processing technology, easy industrial production, and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

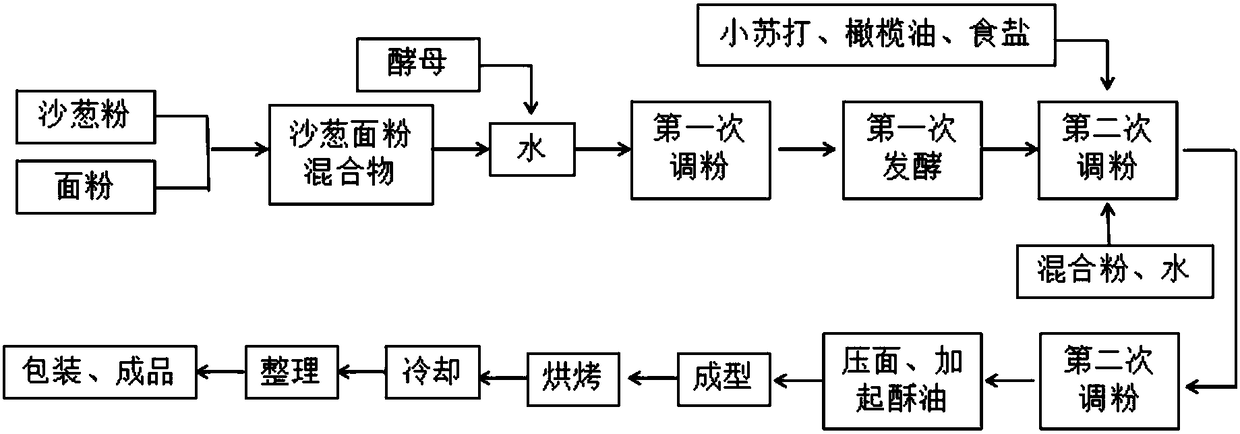

[0048] The preparation technology of the onion dietary fiber soda cracker is as attached figure 1 As shown, the specific preparation process is:

[0049] 1. Preparation of shallot powder

[0050] Put the fresh shallots in a -80°C refrigerator to freeze, and then put them in a freeze dryer for freeze-drying. After 24 hours, take out the freeze-dried slices of shallots from the freeze dryer and put them in a grinder for grinding. Grind until no scallion segments are visible to the naked eye, then stop grinding for 30 seconds, pass through a 200-mesh sieve to remove oversized scallion particles that do not meet the requirements, and obtain uniform and fine scallion powder, put it in a sealed bag for later use.

[0051] 2. The first powder adjustment and fermentation

[0052] ①Weigh 100g of wheat flour and add appropriate amount of shallot powder and put it in a glass bowl to get mixed flour;

[0053] ② Weigh 50% of the total mixed powder and pour it into a fermentation contain...

Embodiment 1-5

[0069] According to the above-mentioned preparation process, soda biscuit with dietary fiber of scallion was prepared. The difference between Examples 1-5 is that the ratio of raw materials is different, and the mass percentage of specific ingredients is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com