A monodisperse or supported phosphorus-containing metal compound as a catalyst for hydrogen storage material hydrolysis hydrogen system

A hydrogen storage material and phosphide technology, applied in the field of hydrogen storage material hydrolysis hydrogen system, can solve the problems of restricting the commercialization of catalysts and the instability of nanoparticles to oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

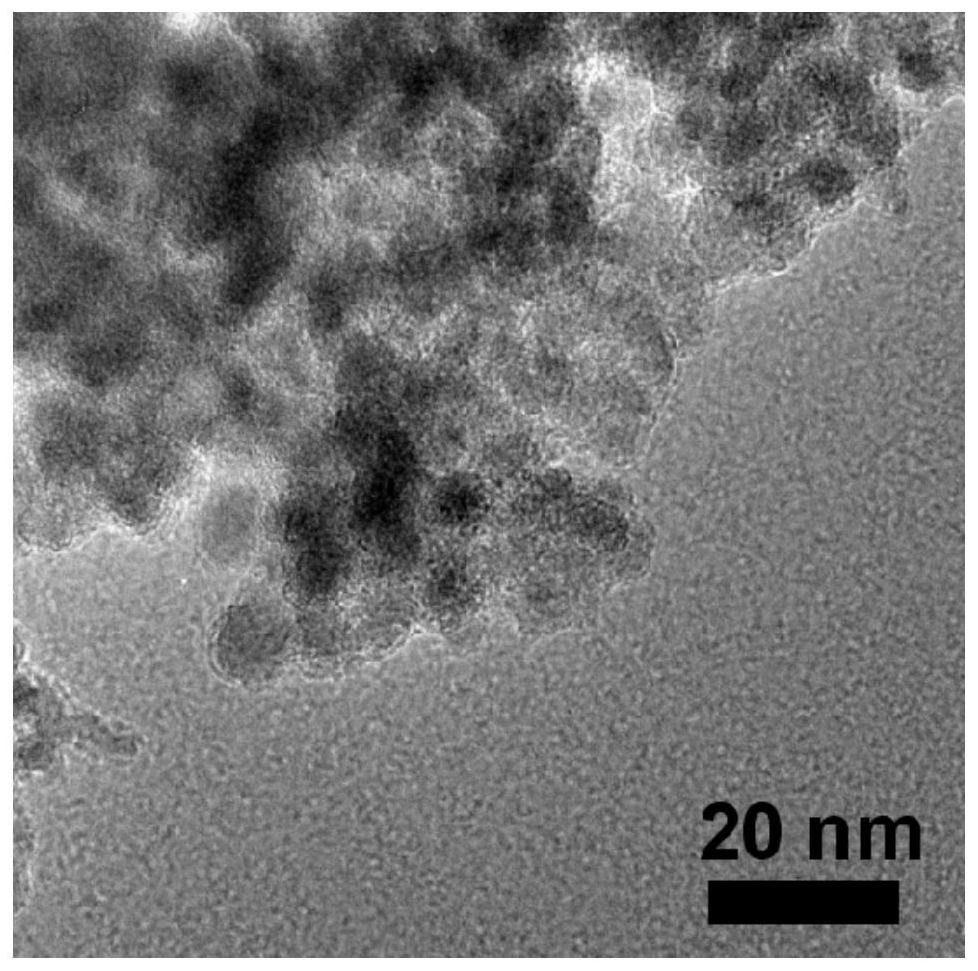

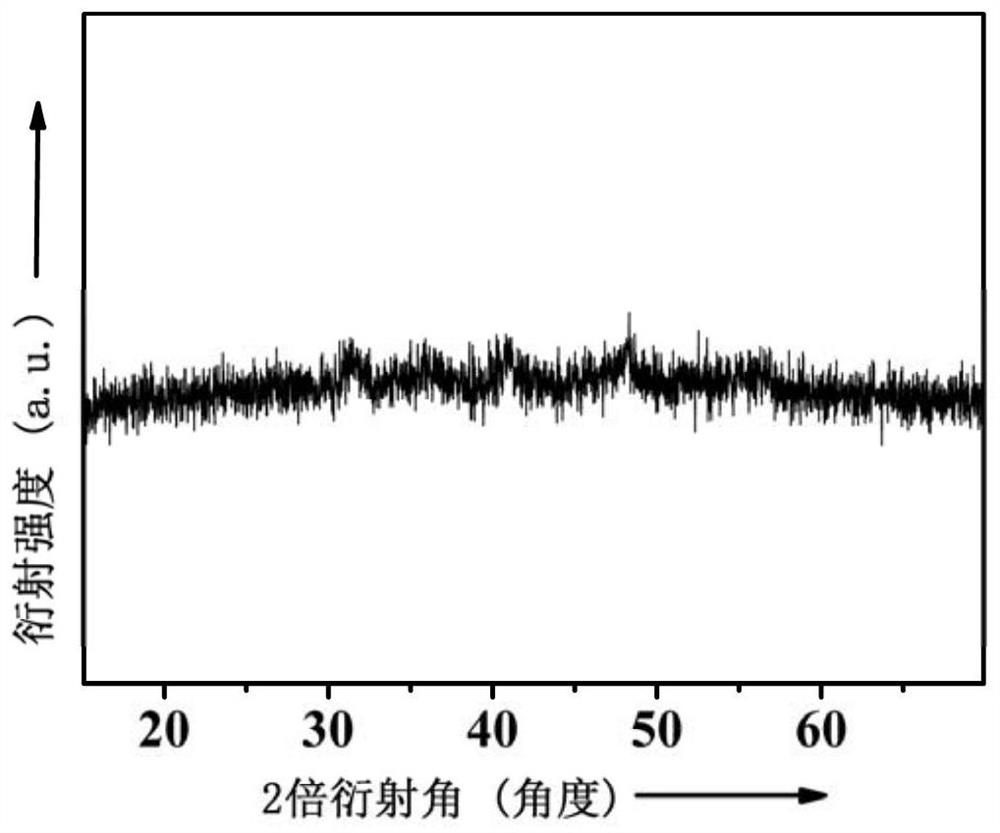

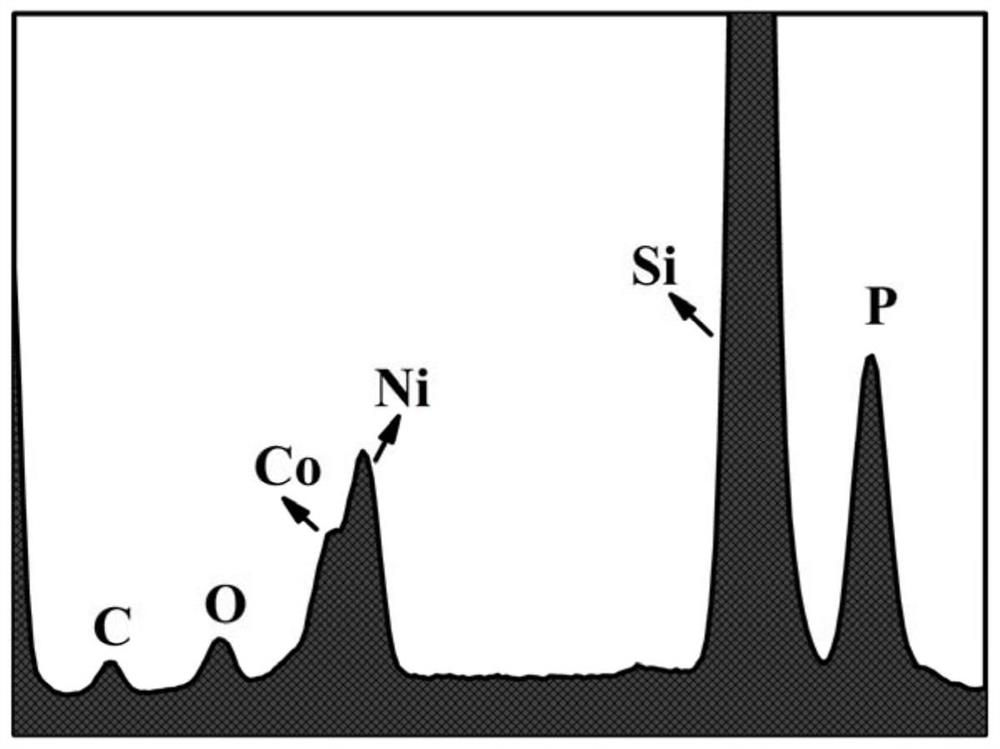

[0099] A cobalt nickel phosphide (Ni 0.7 Co 1.3 P) the preparation method of catalyst, comprises the steps:

[0100] 1) Mix 250 mg of sodium citrate, 2.0 g of sodium hydroxide and 80 mL of distilled water to obtain a mixed solution;

[0101] 2) Dissolve 350 mg of nickel nitrate hexahydrate and 650 mg of cobalt nitrate hexahydrate in 20 mL of distilled water to obtain a metal salt solution; slowly add the metal salt solution into the mixed solution, stir at room temperature for 1 h after the dropwise addition, and then collect the precipitate by centrifugation and use Washed with distilled water, and fully dried to remove water at 373K to obtain a precursor;

[0102] 3) 200 mg of the precursor and 1000 mg of phosphate are thoroughly mixed and ground, the powder is placed in a tube furnace after grinding, and the tube furnace is heated from room temperature to 573K at a heating rate of 5K / min under an argon flow, and at Calcined at this temperature for 2h, then cooled to room...

Embodiment 2

[0105] A cobalt nickel phosphide (Ni 0.7 Co 1.3 P) the preparation method of catalyst, comprises the steps:

[0106] 1) 350mg of nickel nitrate hexahydrate, 650mg of cobalt nitrate hexahydrate and 20mL of distilled water were mixed to obtain a mixed solution;

[0107] 2) 1g of red phosphorus was added to the mixed solution, and then hydrothermally reacted at 473K for 20h; after the reaction was completed, it was cooled to room temperature, and the precipitate was collected by centrifugation and washed with distilled water to obtain cobalt nickel phosphide (Ni 0.7 Co 1.3 P).

Embodiment 3

[0109] A cobalt nickel phosphide (Ni 0.7 Co 1.3 P) the preparation method of catalyst, comprises the steps:

[0110] 1) 350mg of nickel nitrate hexahydrate, 650mg of cobalt nitrate hexahydrate and 20mL of distilled water were mixed to obtain a mixed solution;

[0111] 2) Add 400mg white phosphorus to the mixed solution, then carry out a hydrothermal reaction at 423K for 5h; after the reaction is completed, cool to room temperature, collect the precipitate by centrifugation and wash the precipitate with distilled water to obtain cobalt nickel phosphide (Ni 0.7 Co 1.3 P).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com