Moving device for locomotive mounting

A technology of mobile devices and locomotives, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc. It can solve the problems of enterprise benefit reduction and production efficiency reduction, so as to increase benefits, improve production efficiency, The effect of reducing labor cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

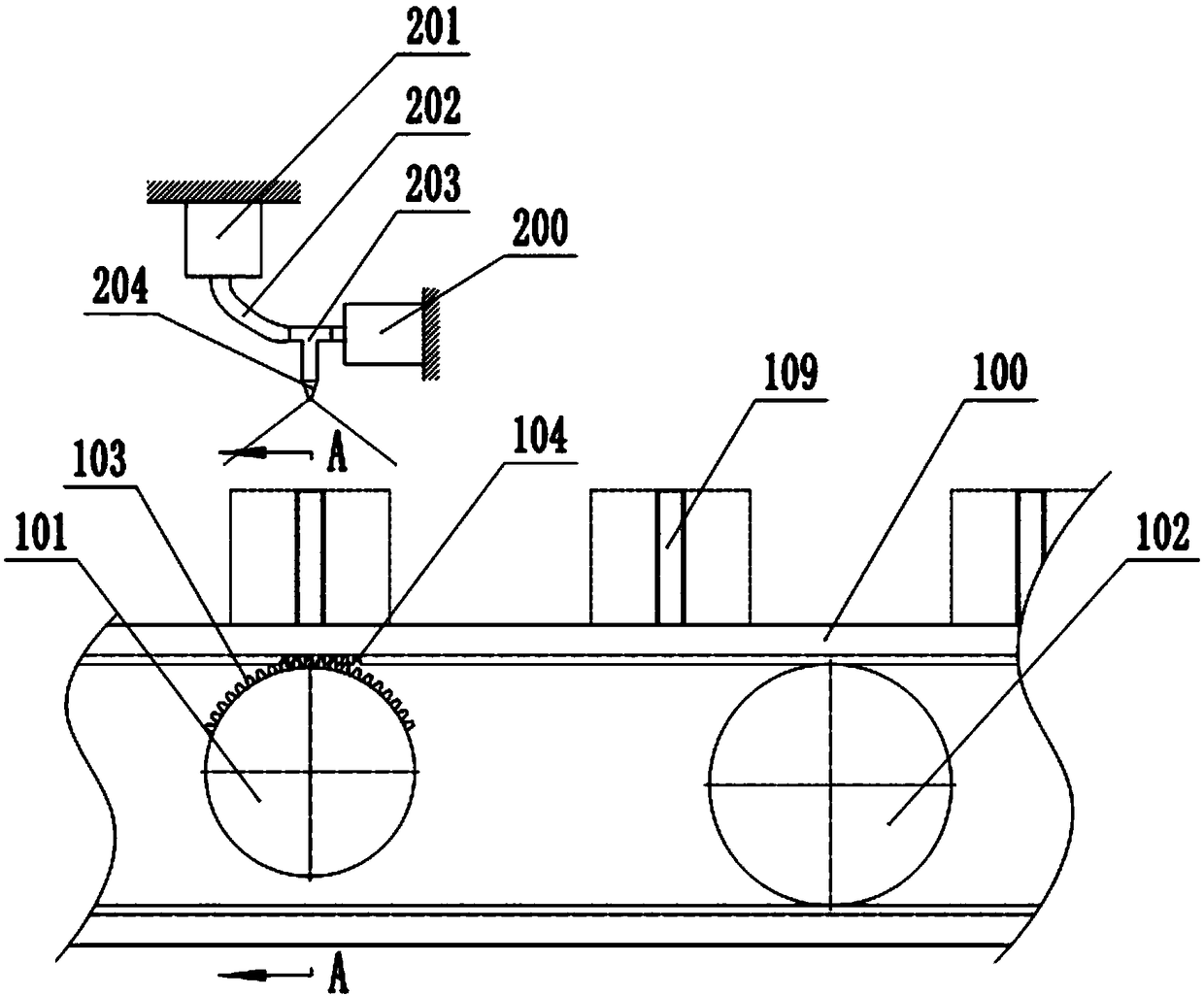

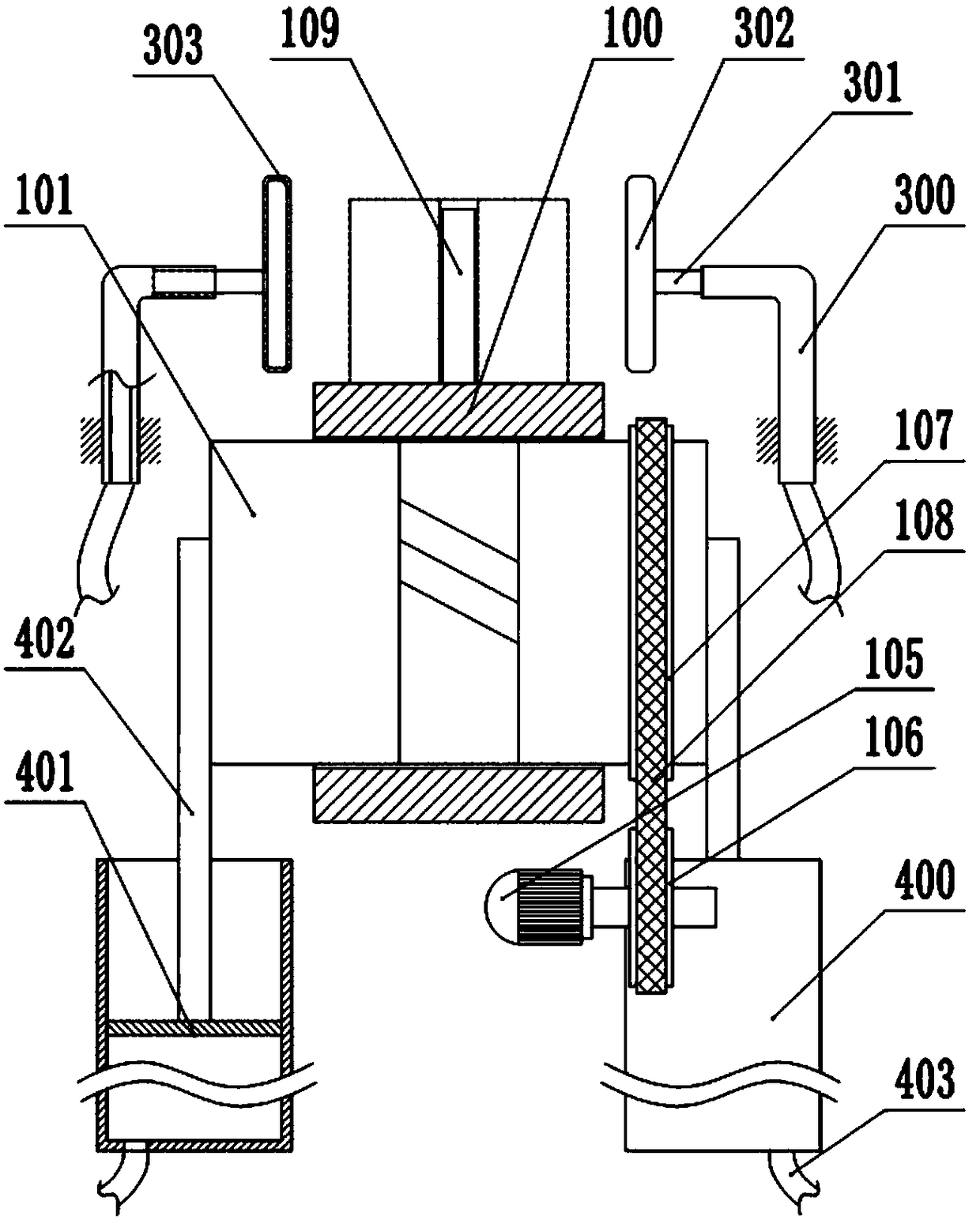

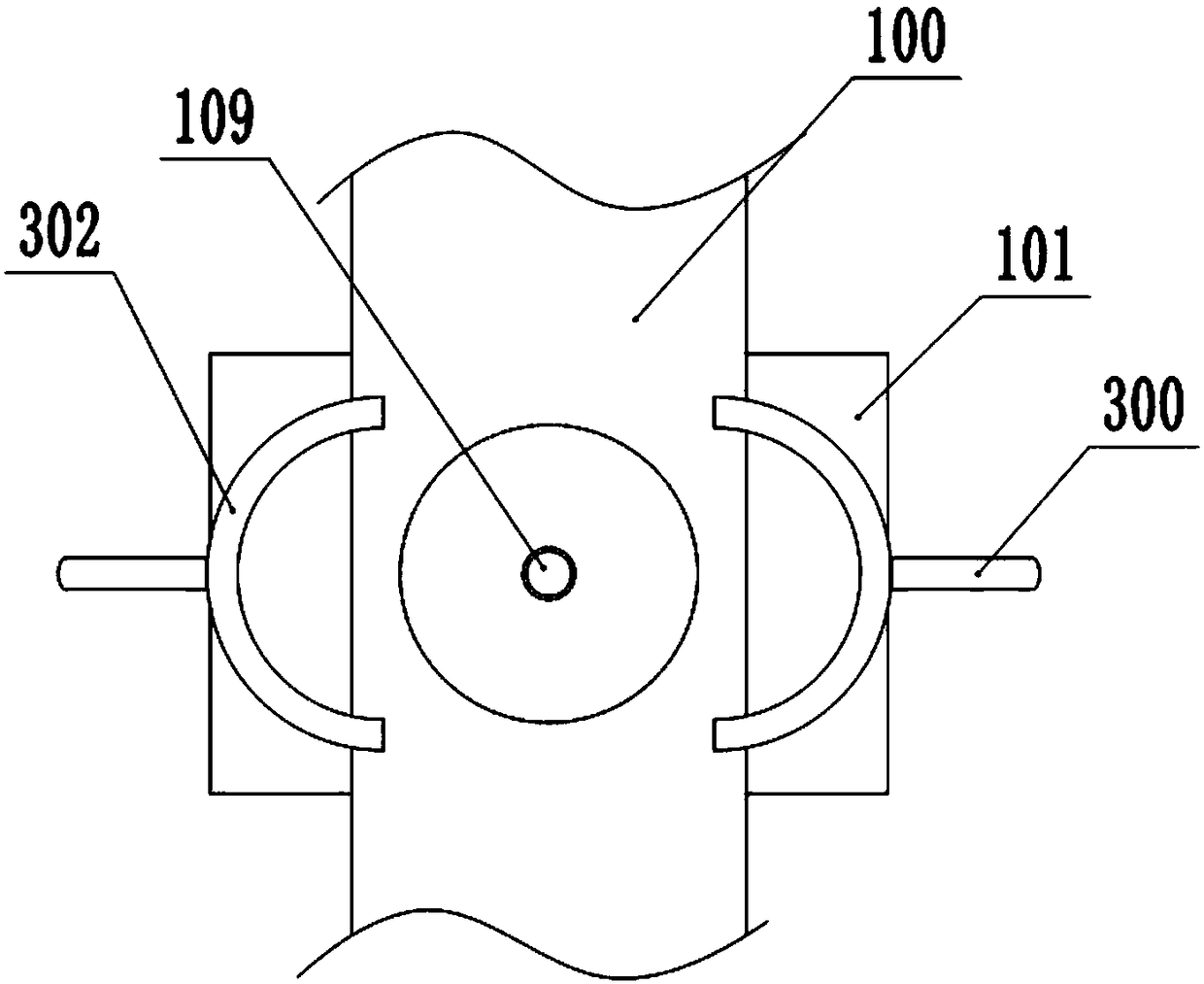

[0028] The reference signs in the accompanying drawings include: conveyor belt 100, drive shaft 101, support shaft 102, convex tooth segment 103, internal teeth 104, motor 105, driving pulley 106, driven pulley 107, belt 108, positioning rod 109 , paint can 200, air outlet pump 201, air outlet pipe 202, tee pipe 203, nozzle 204, auxiliary rod 300, support rod 301, positioning plate 302, air hole 303, cylinder 400, piston 401, piston rod 402, air supply pipe 403 .

[0029] The embodiment is basically as figure 1 and figure 2 Shown:

[0030] Locomotive-mounted mobile device, which includes a frame on which a conveying unit and a painting unit are arranged, such as figure 1 The transmission unit shown includes a conveyor belt 100, a drive shaft 101 and a plurality of support shafts 102, wherein the conveyor belt 100 is horizontally arranged and sleeved on the support shaft 102, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com