Combined type oxide skin removing equipment and removing method

A kind of oxide scale and composite technology, applied in the direction of metal processing equipment, grinding/polishing equipment, other manufacturing equipment/tools, etc., to achieve the effect of small electrode spacing, high utilization rate of electricity, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

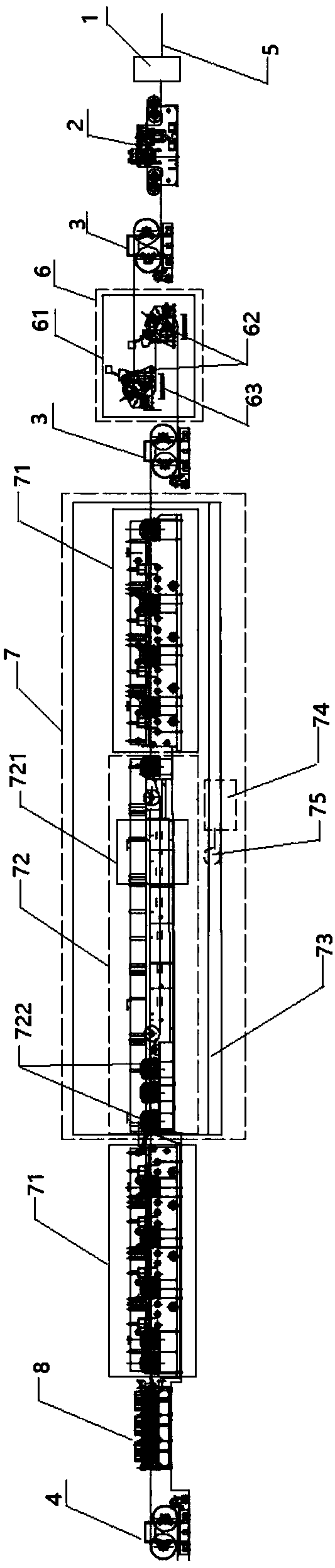

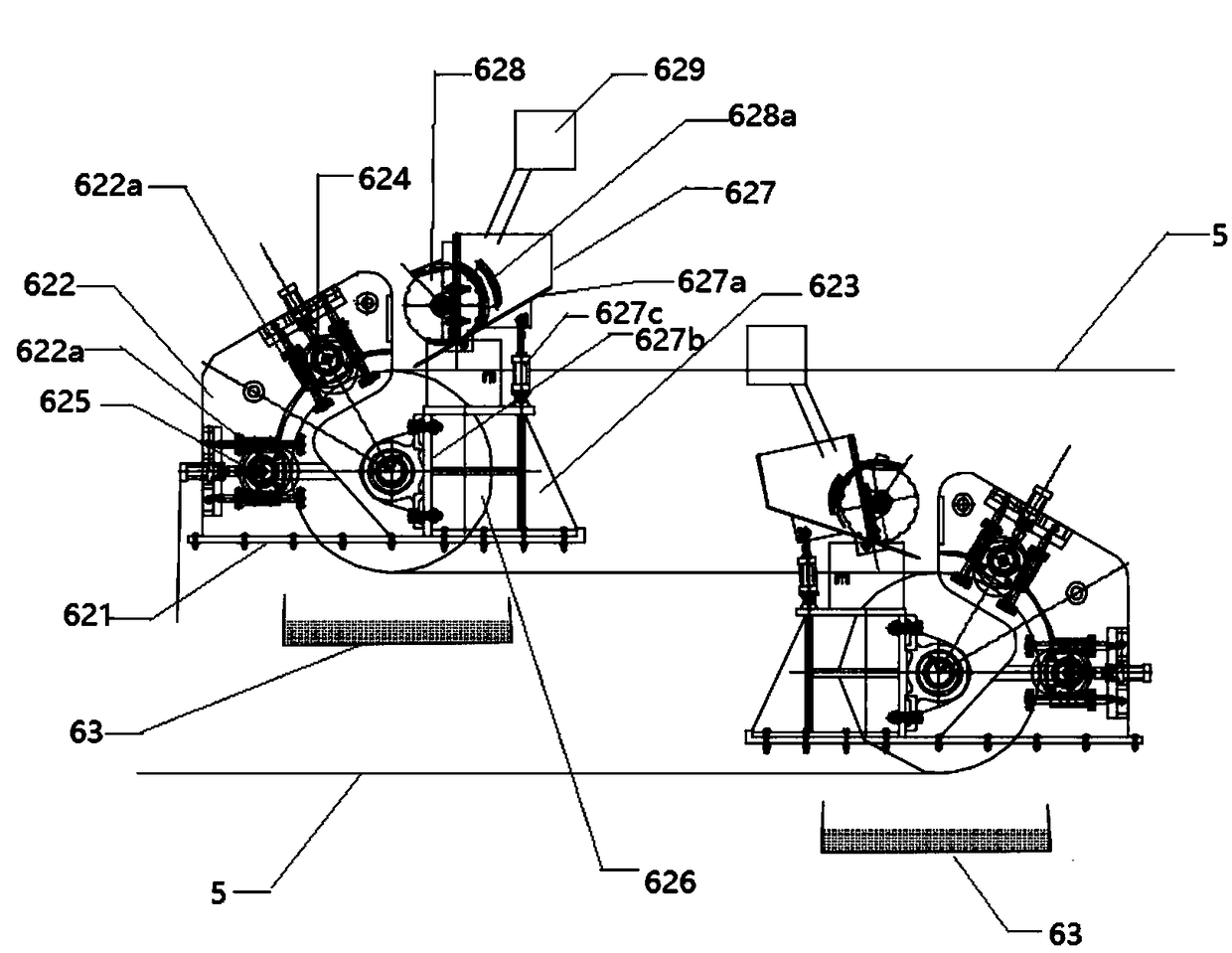

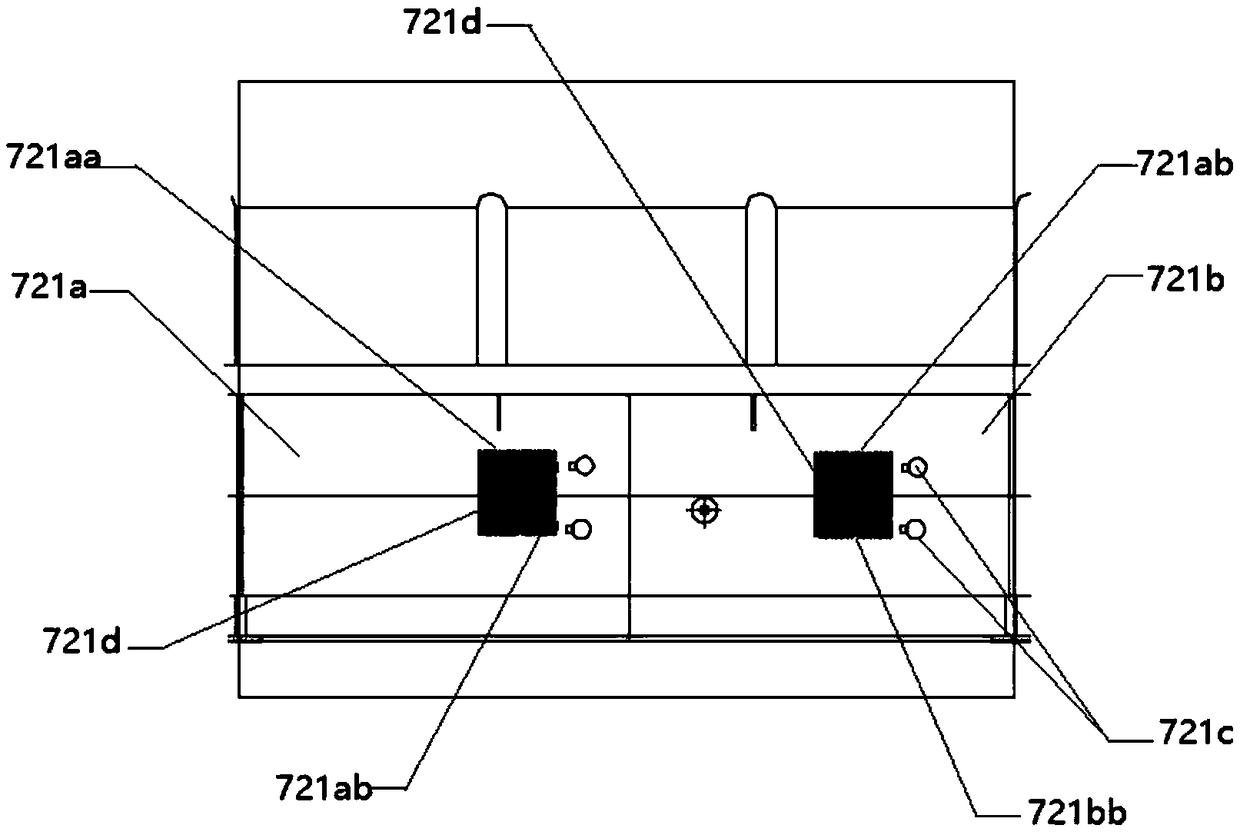

[0028] Such as Figure 1-4 As shown, a compound descaling equipment of the present invention includes an uncoiler 1, a stretch bending scale breaker 2, a belt power tensioner 3, and a winder 4, and the uncoiler 1 is used to roll metal sheets 5 Unfold and transport to the stretch bending scale breaking machine 2, the side of the uncoiler 1 is provided with a stretch bending scale breaking machine 2, and the stretch bending scale breaking machine 2 is used to bend the thicker scale in the process of stretch bending crushing in the middle, one side of the stretch-bending scale breaker 2 is provided with several driving tension machines 3, and the driving tension machines 3 include a first tension roller 31, a second tension roller 32, a power motor (not shown ), the horizontal side of the first tension roller 31 is provided with the second tension roller 31, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com