Tooling for Gearbox Machining

A gearbox and gear technology, applied in metal processing, etc., can solve problems such as unfavorable resource utilization, difficulty in realization, complicated operation process, etc., and achieve the effects of improving turning efficiency, ensuring stability, and enhancing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

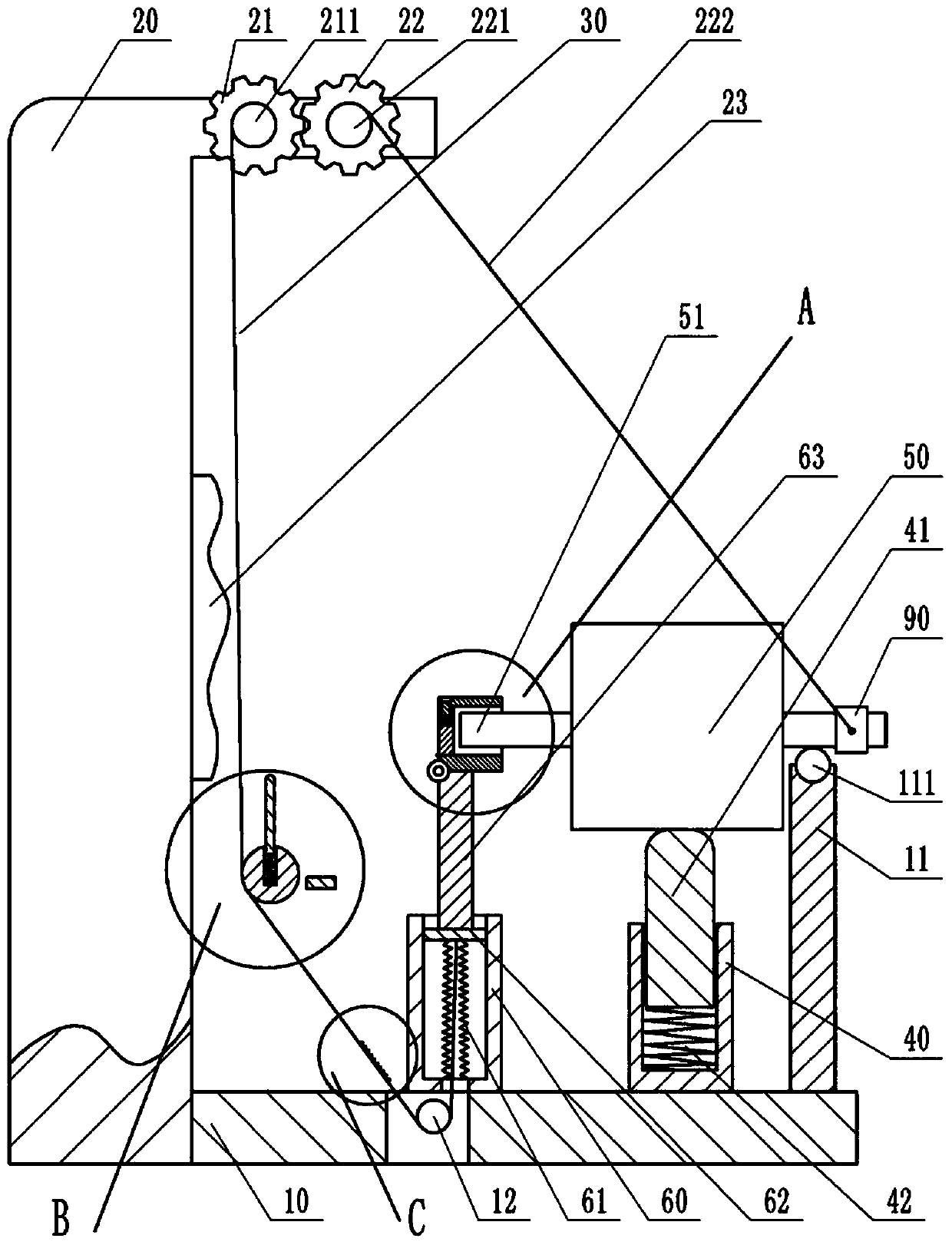

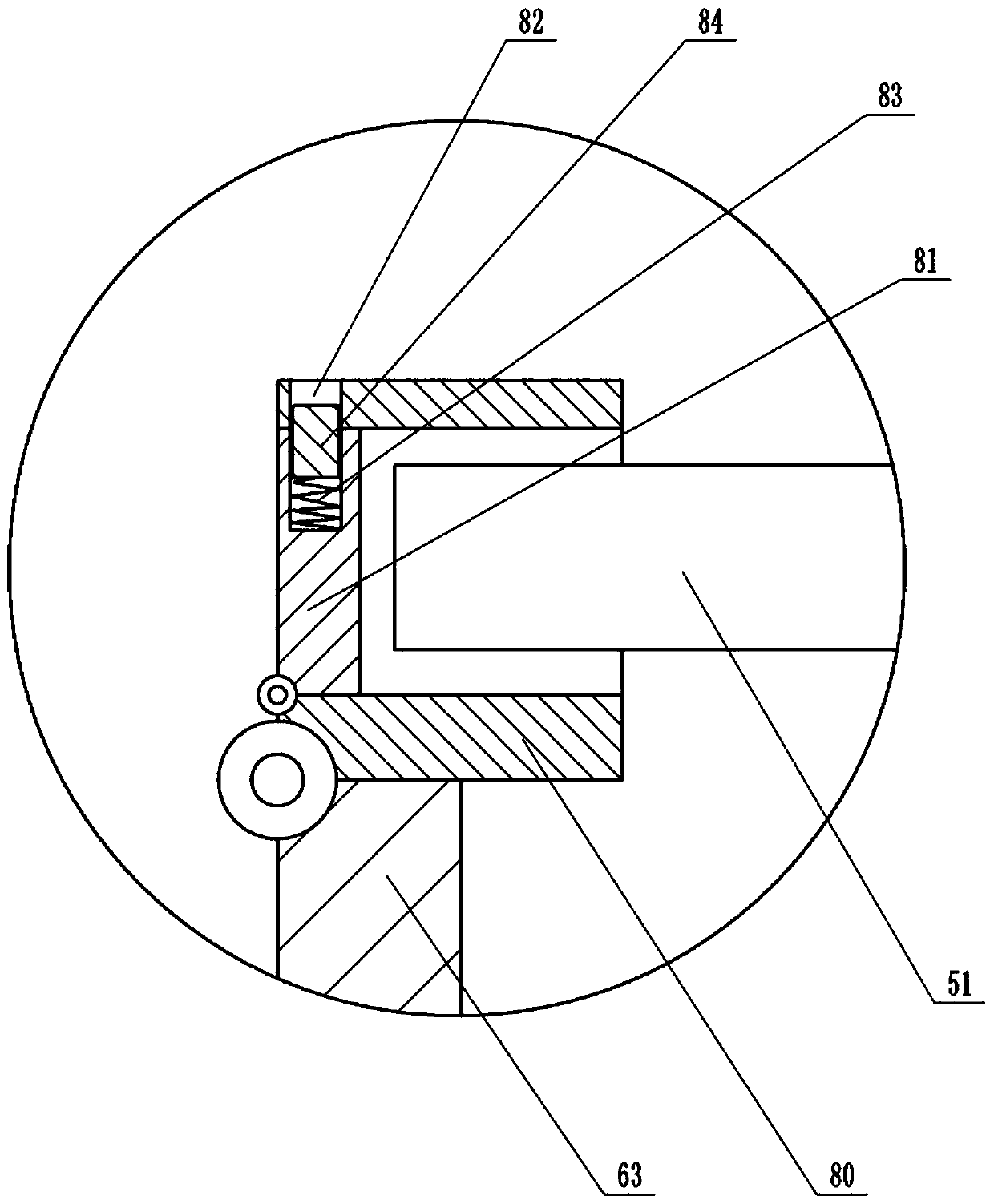

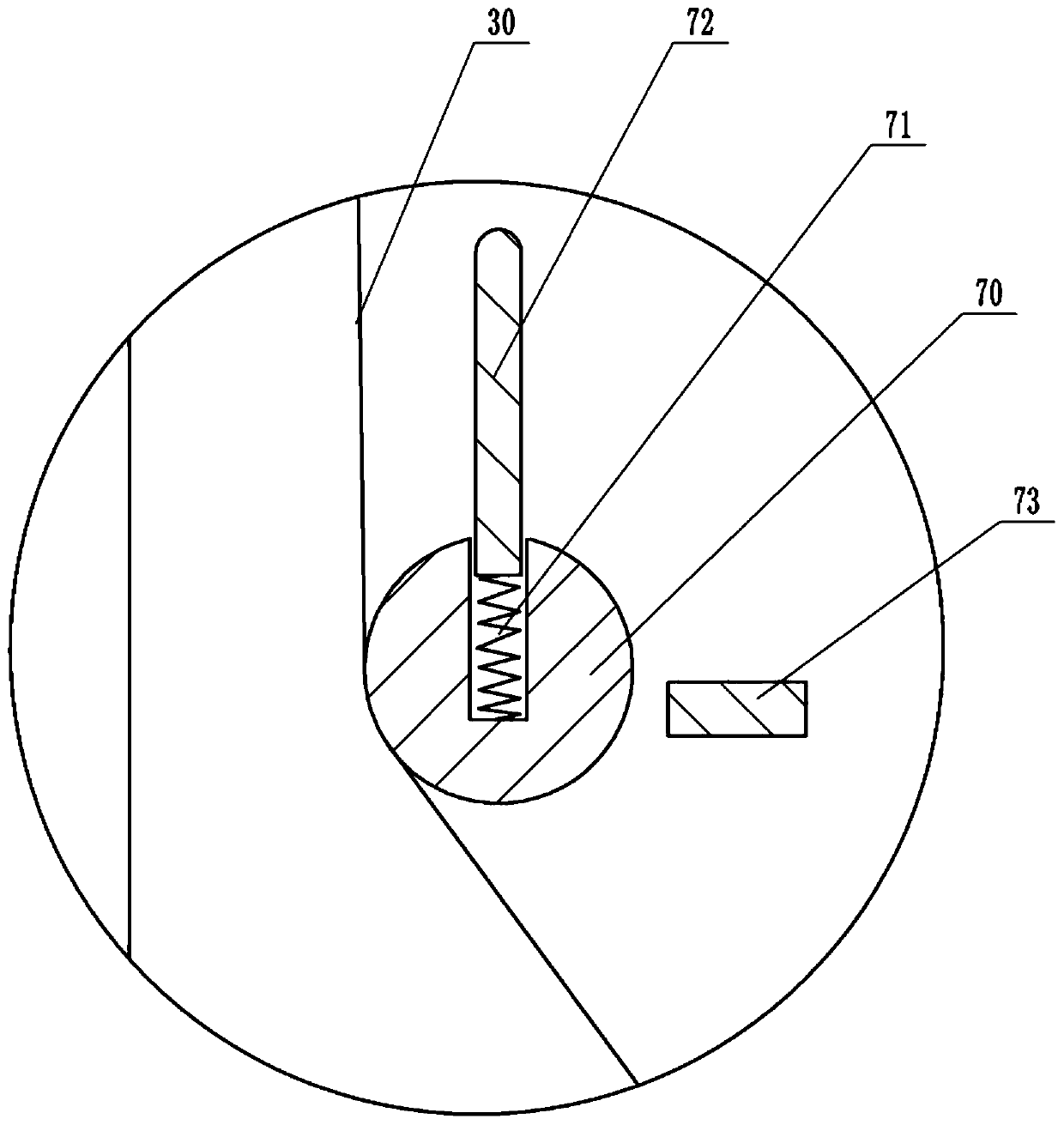

[0023] Instructions attached Figures 1 to 5 The reference numerals in include: mounting seat 10, column 11, ball 111, frame 20, second gear 21, rewinding wheel 211, first gear 22, wire wheel 221, stay wire 222, buffer pad 23, stay cord 30 , protruding tooth 31, limit cylinder 40, top column 41, third spring 42, gear box 50, axle 51, piston cylinder 60, bellows 61, piston 62, pillar 63, roller 70, second spring 71, top Rod 72 , limit block 73 , annular groove 74 , locking teeth 75 , turning cylinder 80 , closing door 81 , through groove 82 , first spring 83 , connecting block 84 , and collar 90 .

[0024] Such as figure 1 As shown, the gear box processing tooling includes a frame 20, an installation unit, a push-off unit, a pulling unit and a top unit, and the installation unit includes a mounting seat 10, a collar 90, and a column 11 and For the turning mechanism, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com