Blast furnace injection pulverized coal preparation method with semi-coke as blast furnace injection raw material

A technology for blue carbon and pulverized coal is applied in the field of preparing blast furnace pulverized coal, which can solve problems such as difficulty in grinding blue carbon, and achieve the effects of improving the utilization rate and production efficiency of blue carbon, reducing production costs and reducing sharpness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

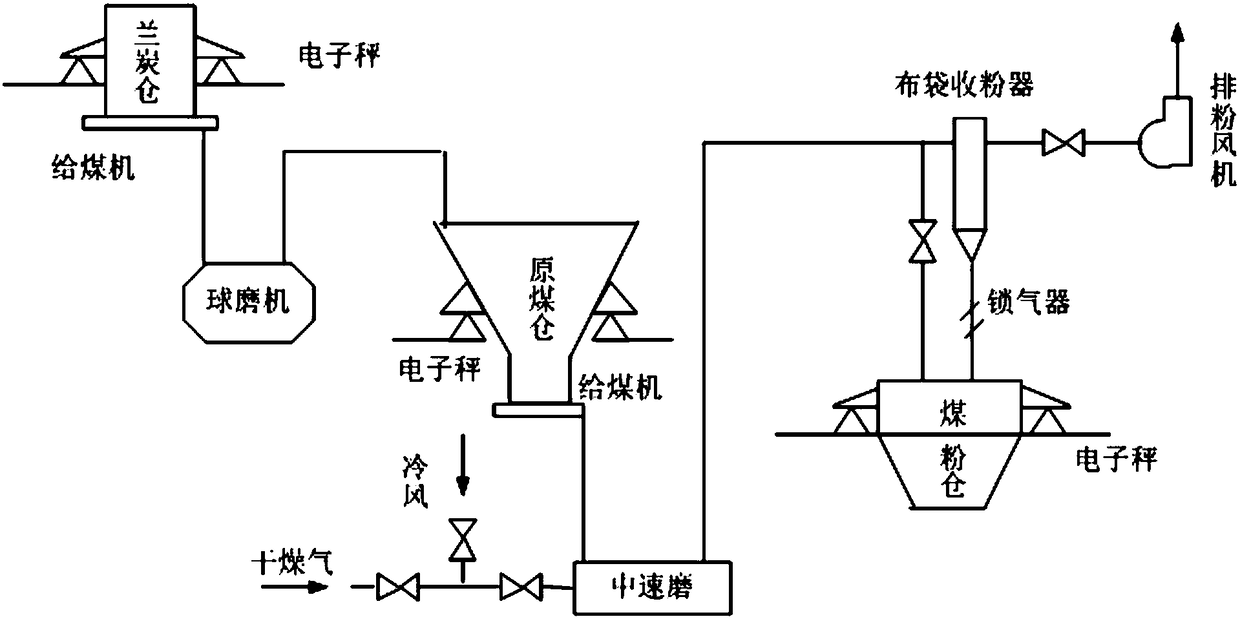

[0054] This embodiment provides a method for preparing pulverized coal for blast furnace injection using semi-coke as a raw material for blast furnace injection, including steps:

[0055] The semi-coke block with a particle size of about 10mm (technical index parameters are as shown in Table 4) is separately ground by a ball mill to prepare a prefabricated powder with a particle size of about 1.5mm;

[0056] Mix semi-coke prefabricated powder with bituminous coal with a particle size of about 15mm (technical indicators are shown in Table 5) according to a mass ratio of 1:1, and then send it to a medium-speed mill for final grinding, so that the ground semi-coke is mixed with coal powder (The technical indicators are shown in Table 6), the particle content of particle size less than 0.0750mm (-200 mesh) is higher than 70%;

[0057] The semi-coke mixed with pulverized coal is used for blast furnace injection to obtain pulverized coal for blast furnace injection.

[0058] Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com