Cover plate applied to polycrystalline silicon ingot casting crucible

A technology of polysilicon and cover plate, applied in polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as low-efficiency electrical performance, steel wire wear, disconnection, etc., to reduce eddy current, reduce impurities, and improve products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

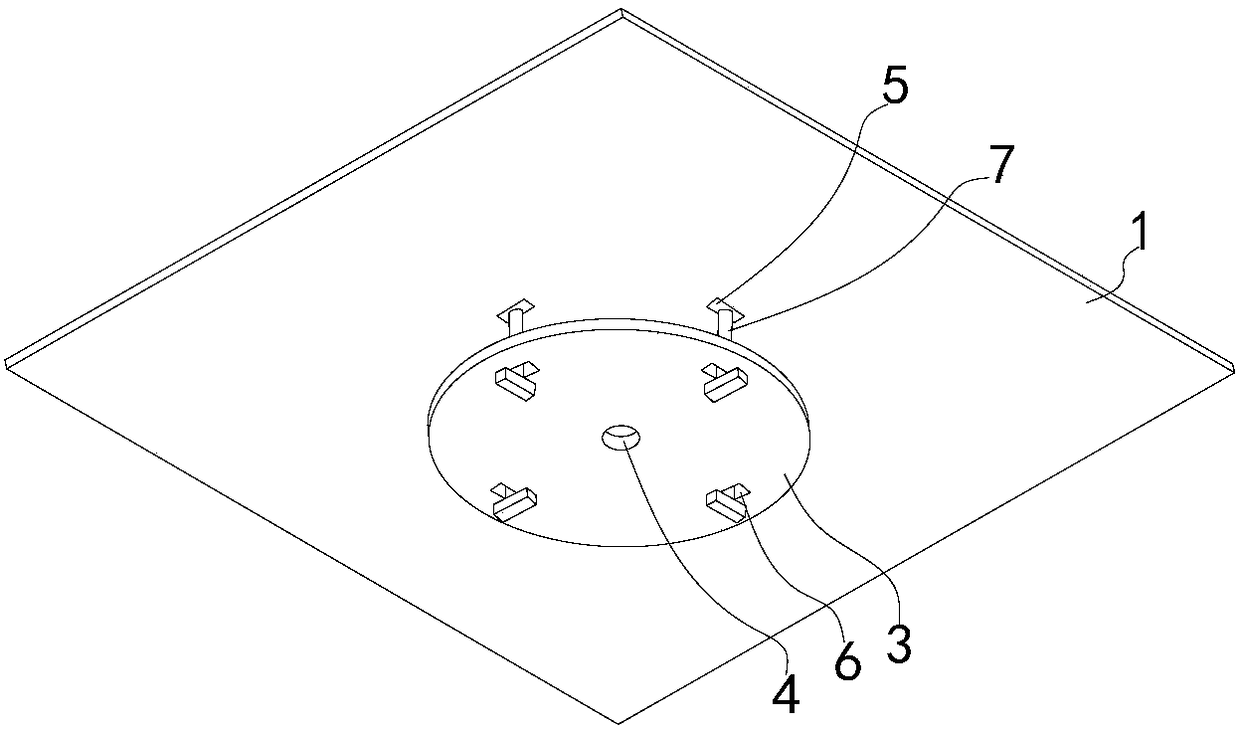

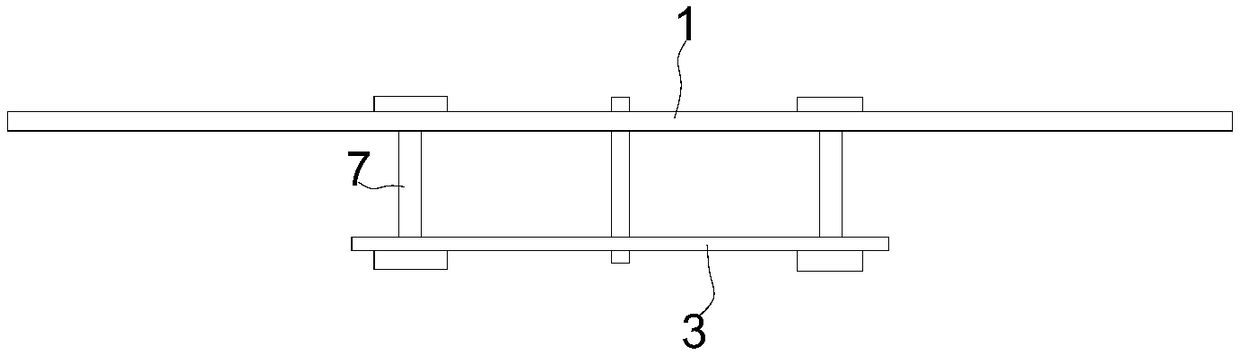

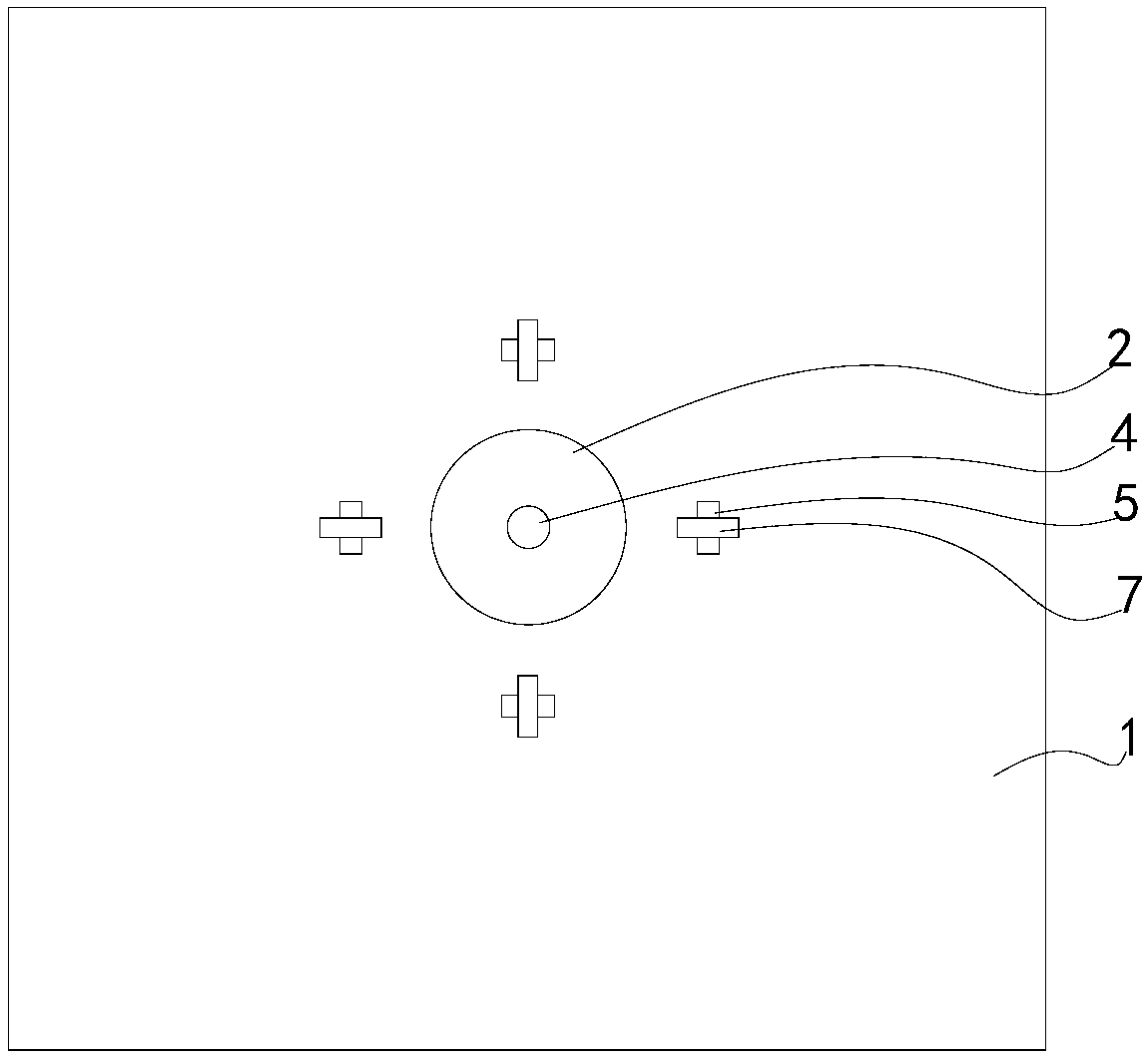

[0015] Such as figure 1 , figure 2 , image 3 As shown, the cover plate for the polysilicon ingot crucible proposed by the present invention comprises a cover plate body 1, an air inlet 2 is provided in the cover plate body, and an air flow baffle 3 is installed under the cover plate body, and the air flow baffle 3 is arranged below the cover plate body. The position corresponds to the position of the air intake hole, and there is a gap for the air flow to discharge between the cover plate body and the air flow baffle. In this embodiment, both the air intake hole and the airflow baffle are circular, the central axis of the air intake hole coincides with the central axis of the airflow baffle, and the diameter of the airflow b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap