Manufacturing method of high-transmittance type LED lamp

A technology of LED lamps and manufacturing methods, which is applied to semiconductor devices of light-emitting elements, lighting devices, light sources, etc., to achieve the effects of improved light transmission, reasonable structure, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

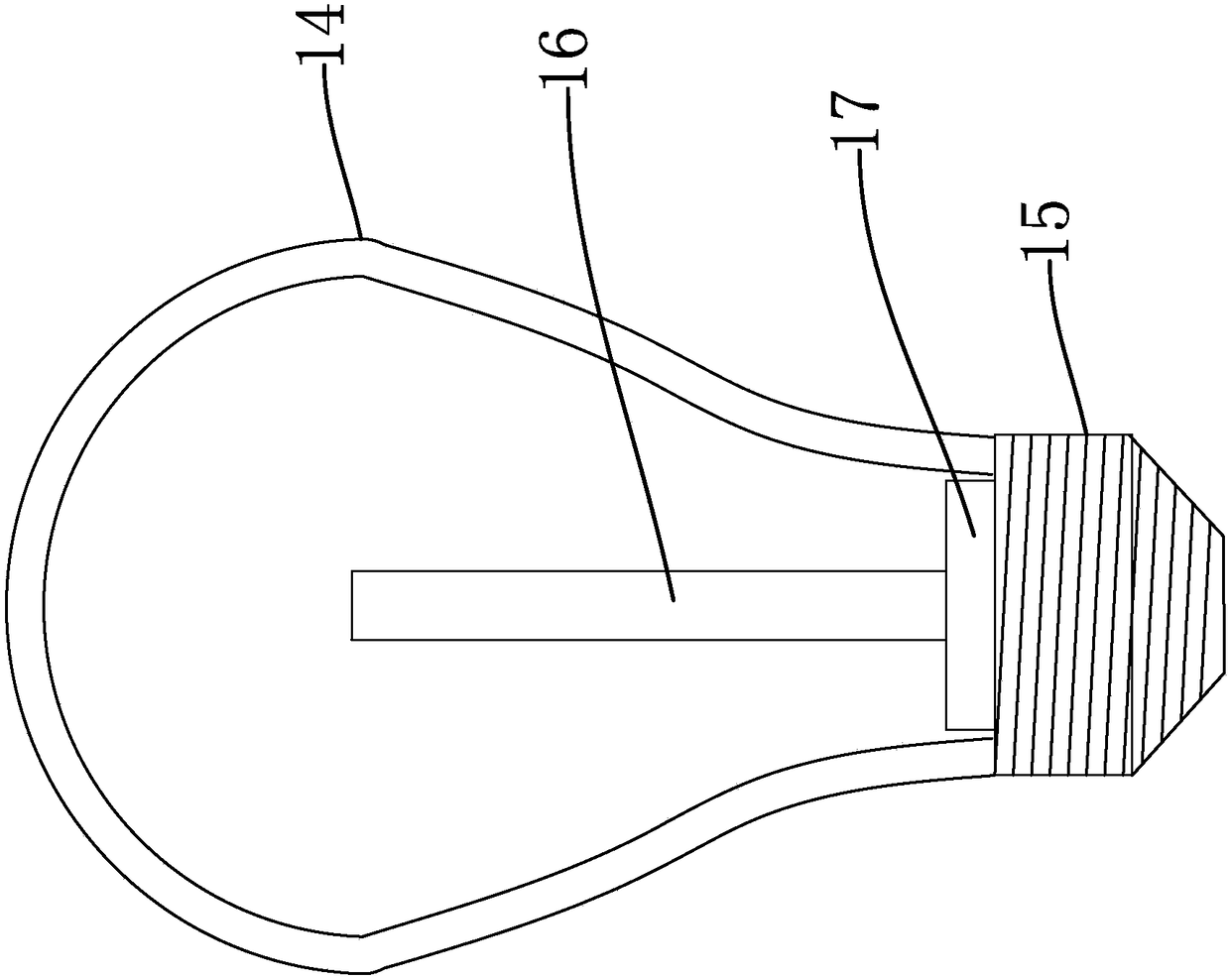

[0039] Such as figure 1As shown, a method for manufacturing a high-transparency LED lamp, the high-transparency LED lamp includes a base 15 and a lamp body 14 connected to the base 15, the lamp body 14 is provided with an LED lamp sheet 16, and the LED lamp sheet 16 includes a PCB board and a number of lamp beads arranged on the PCB board, the lamp body has a high-permeability layer, and the base 15 is also provided with a control circuit assembly 17;

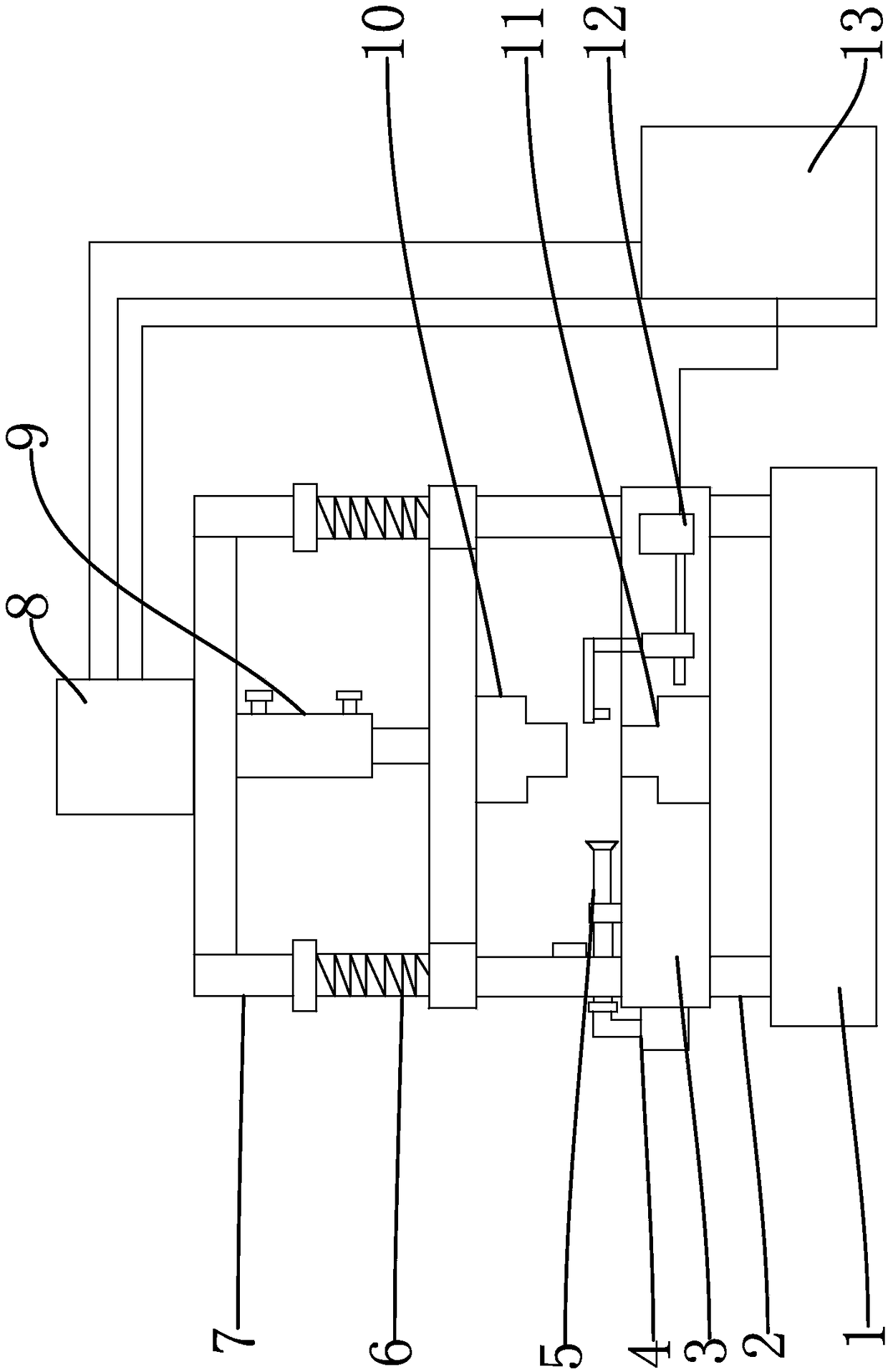

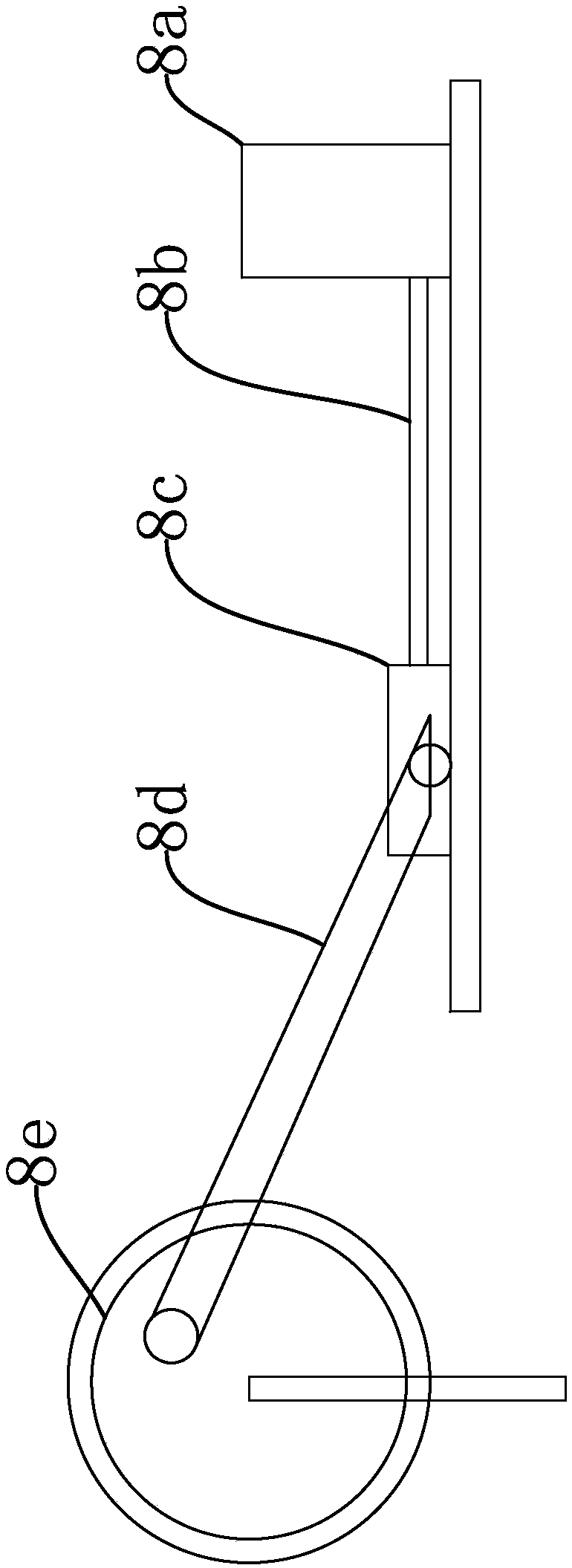

[0040] The manufacturing method includes the following steps: a. Stamping and forming of the base 15: stamping raw materials into the base 15 through an LED lamp processing device; b. Preparation of a high-transparency layer: selecting a lamp body 14 that matches the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com