A Method of Measuring Interface Thermal Resistance Between Two Solids Using Hot Wire Method

A technology of interface thermal resistance and hot wire method, which is applied in the field of measuring the interface thermal resistance between two solids by hot wire method, can solve the problems of high equipment purchase cost and large initial investment, and achieve the effect of low cost, accurate precision and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below.

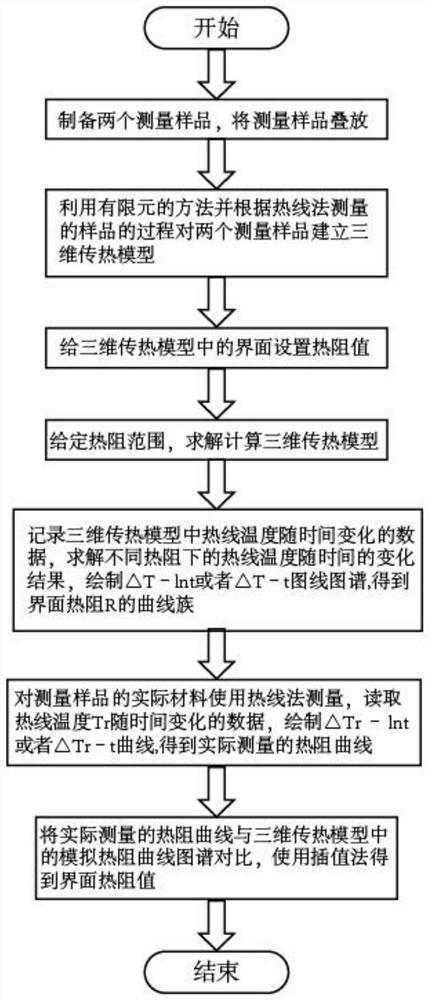

[0040] Such as Figure 1-Figure 3 Shown, concrete steps of the present invention are as follows: a kind of method for measuring interfacial thermal resistance between two solids with hot wire method, comprises the following steps:

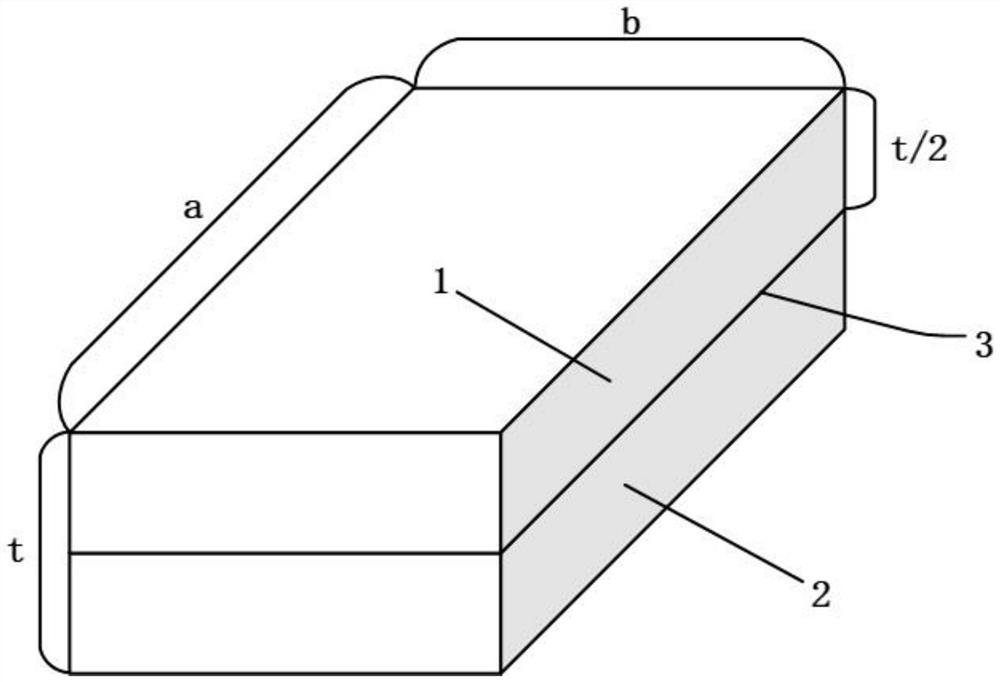

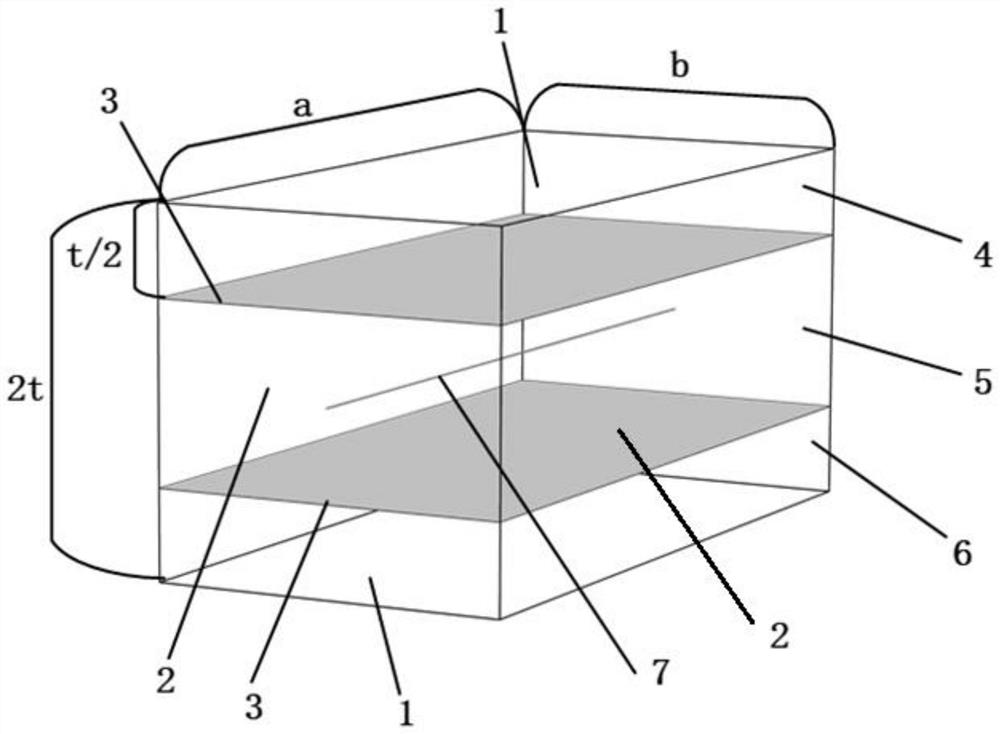

[0041] Step 1: First prepare a measurement sample, the thickness of the measurement sample is marked as t, the length is marked as a, and the width is marked as b. The measurement sample includes material I1 and material II2, and the contact surface of material I1 and material II2 is Interface 3, the thicknesses of material I1 and material II2 can be set according to the needs of the experiment. In this embodiment, the thicknesses of material I1 and material II2 each account for 1 / 2 of the thickness of the measurement sample. Two measurement samples are prepared, and the measurement sample Materials Ⅱ2 are stacked facing each other;

[0042] Step 2: Define the two measurement samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com