Defect position calculation method for detecting welding seam defects through ultrasounds

A technology of defect location and calculation method, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, analyzed materials, etc., which can solve the problems that the field conditions cannot meet the operating space requirements, the inner arc collision of the workpiece, the jamming, and the poor coupling, etc. , to achieve the effect of improving work efficiency and defect detection ability, ensuring quality inspection, and high detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

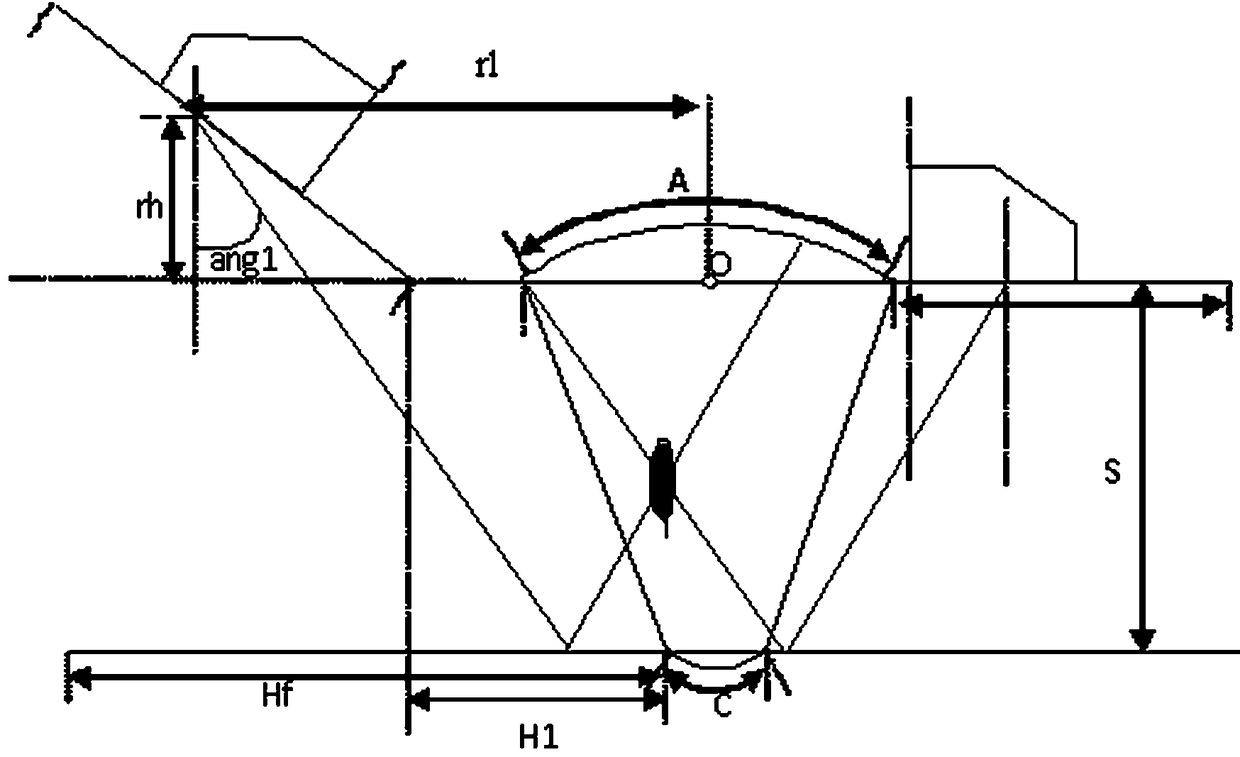

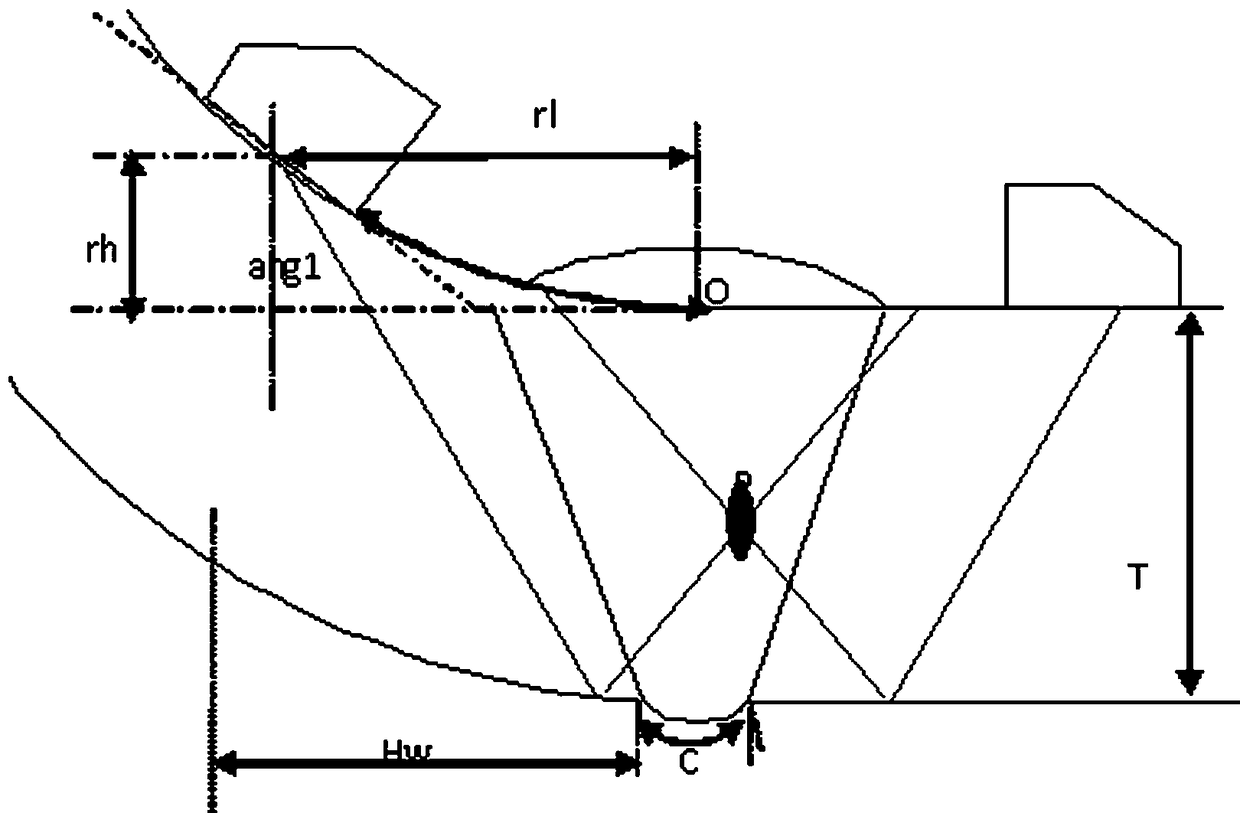

[0049] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0050]In this defect position calculation method for ultrasonic detection of weld defects, the two multi-angle ultrasonic probes of the multi-angle bilateral ultrasonic scanning device are respectively placed on both sides of the weld of the pipeline to be tested, and are placed along the circumference of the pipeline to be tested. Conduct equidistant linear scanning to obtain the weld detection data of each sound ray; determine the zero point of the defect, and calculate the vertical distance and horizontal distance of each point of the defect through each weld detection data to obtain the defect position, among which, The vertical distance takes the upper surface of the straight pipe wall as the zero point. When the defect position is below the zero point, it is recorded as a positive value. When the defect position is above the ze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com