Computational lithography method for model-driven convolution neural network

A convolutional neural network and model-driven technology, applied in the field of computational imaging, can solve problems such as high computational complexity, affecting the imaging quality of the lithography system, and large convergence errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

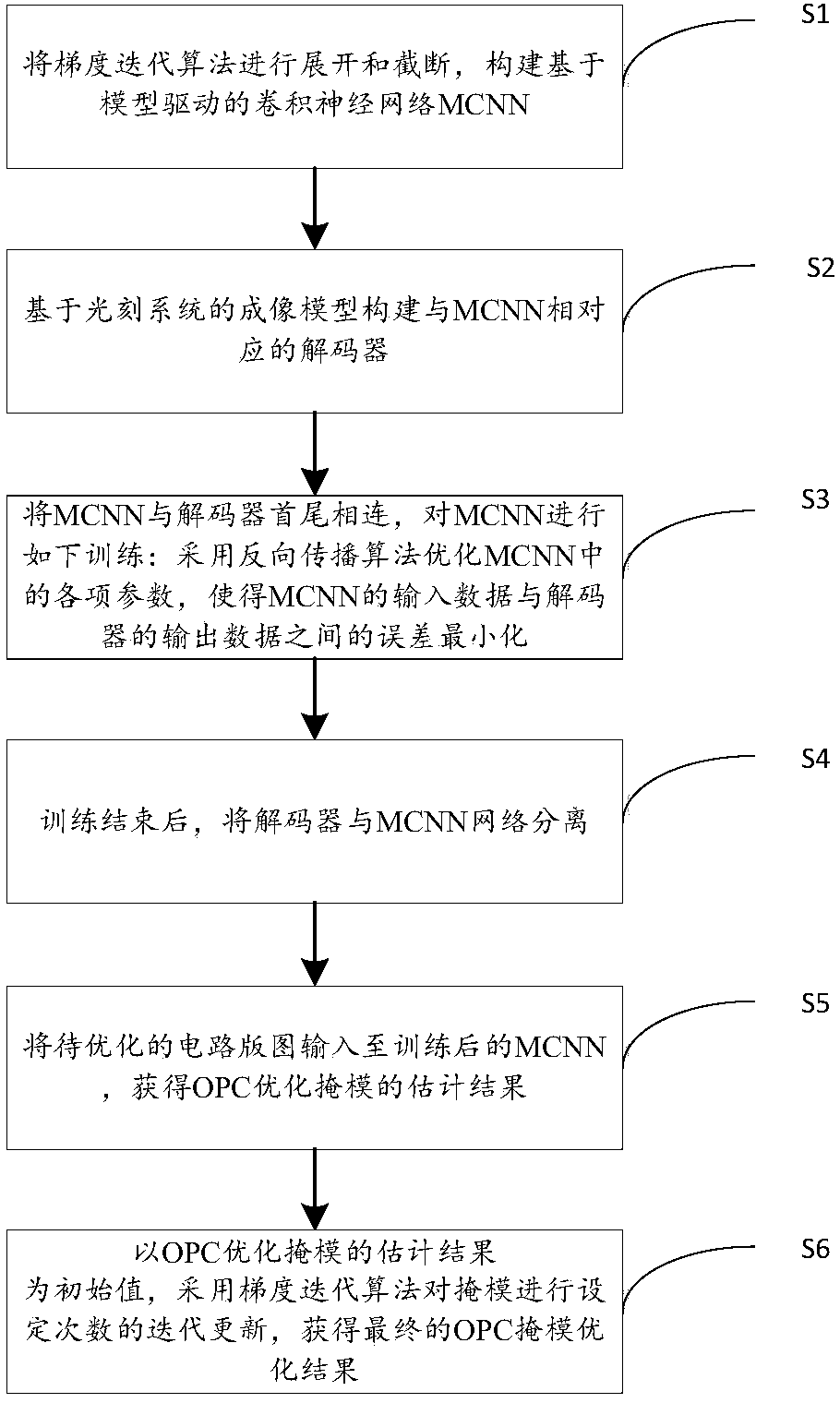

[0085] Please refer to figure 1 , figure 1 A computational lithography method based on a model-driven convolutional neural network provided by an embodiment of the present invention is shown, and the technical solution of the method is as follows:

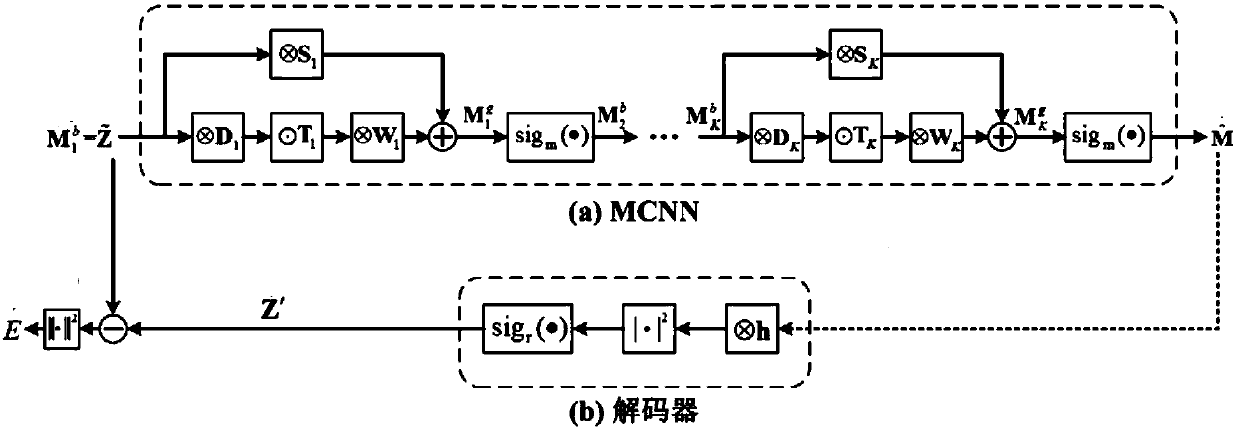

[0086] S1. Expand and truncate the gradient iterative algorithm to construct a model-driven convolutional neural network MCNN.

[0087] The input data of MCNN is the circuit layout to be optimized, and the output data of MCNN is the mask pattern optimized by optical proximity effect correction OPC.

[0088] S2. Build a decoder corresponding to MCNN based on the imaging model of the lithography system.

[0089] The input data of the decoder is the OPC-optimized mask pattern, and the output data of the decoder is the imaging of the lithography system corresponding to the OPC-optimized mask pattern.

[0090...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com