Automatic liquid nitrogen control and supplementing device of high-temperature superconductor strip mechanics experiment machine and method

A high-temperature superconducting strip material and mechanical experiment technology, applied in the field of liquid nitrogen automatic control supply device, can solve the problems of continuous volatilization, low experiment efficiency, high experiment failure rate, etc., to avoid measurement errors, reliable experimental results, and successful experiments high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

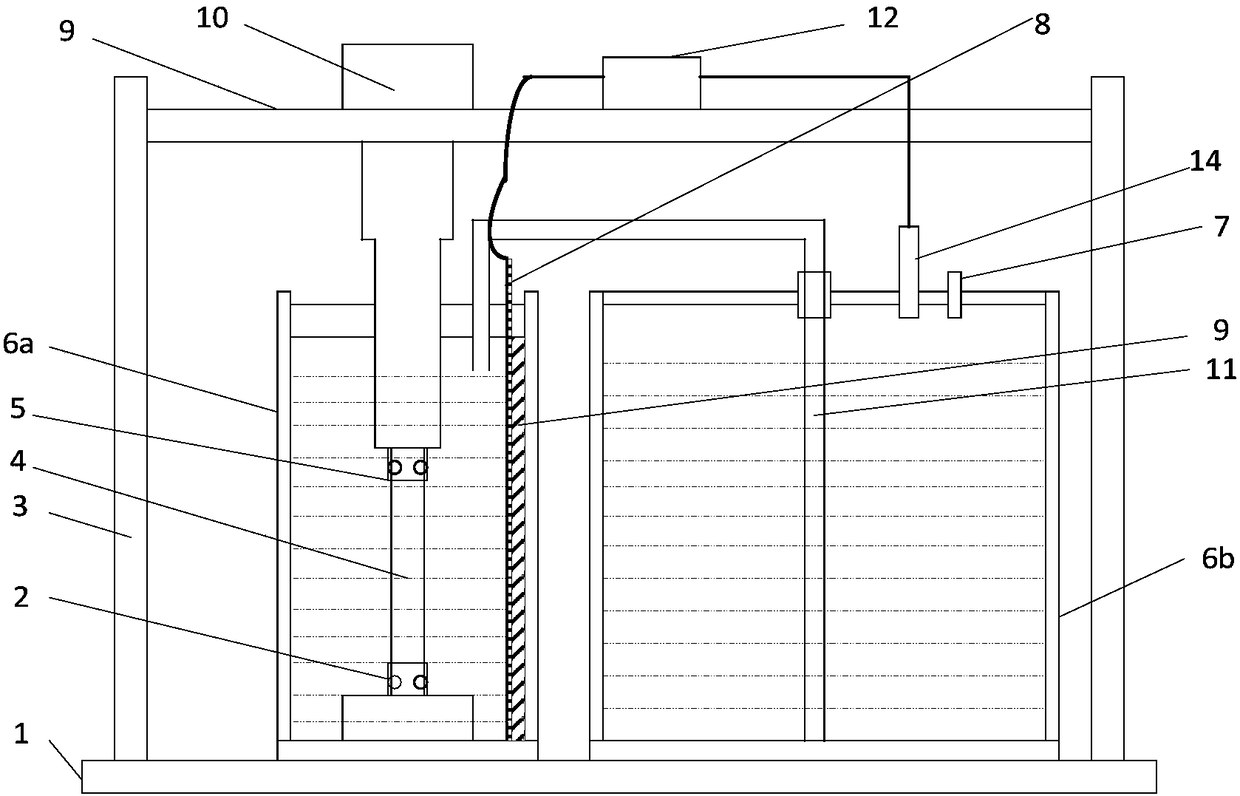

[0023] figure 1 It is shown that a specific embodiment of the present invention is a liquid nitrogen automatic control supply device for a high-temperature superconducting strip mechanical test machine, which consists of;

[0024] Four uprights (3) are fixed on the bottom plate (1), and a top plate (9) is fixed on the top of the uprights (3), and the strip vertical driving mechanism (10) of the high-temperature superconducting strip mechanics testing machine is placed on the top plate (9). Above; the exposed Dewar (6a) of the high-temperature superconducting strip mechanical testing machine is placed on the lower base plate (1) and is located directly below the strip vertical drive mechanism (10), and the strip vertical drive mechanism (10) The driving rod clamps the upper end of the high-temperature superconducting strip (4) in the Dewar (6a) through the upper clamp (5), and the lower end of the high-temperature superconducting strip (4) is clamped and fixed on the Dewar thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com