Friction plate and method for optimizing same to reduce uneven wear

A technology of uniform wear and friction plates, applied in friction linings, design optimization/simulation, instruments, etc., can solve the problems of many optimization parameters, low efficiency, high cost, improve service life, improve efficiency, and avoid wasting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

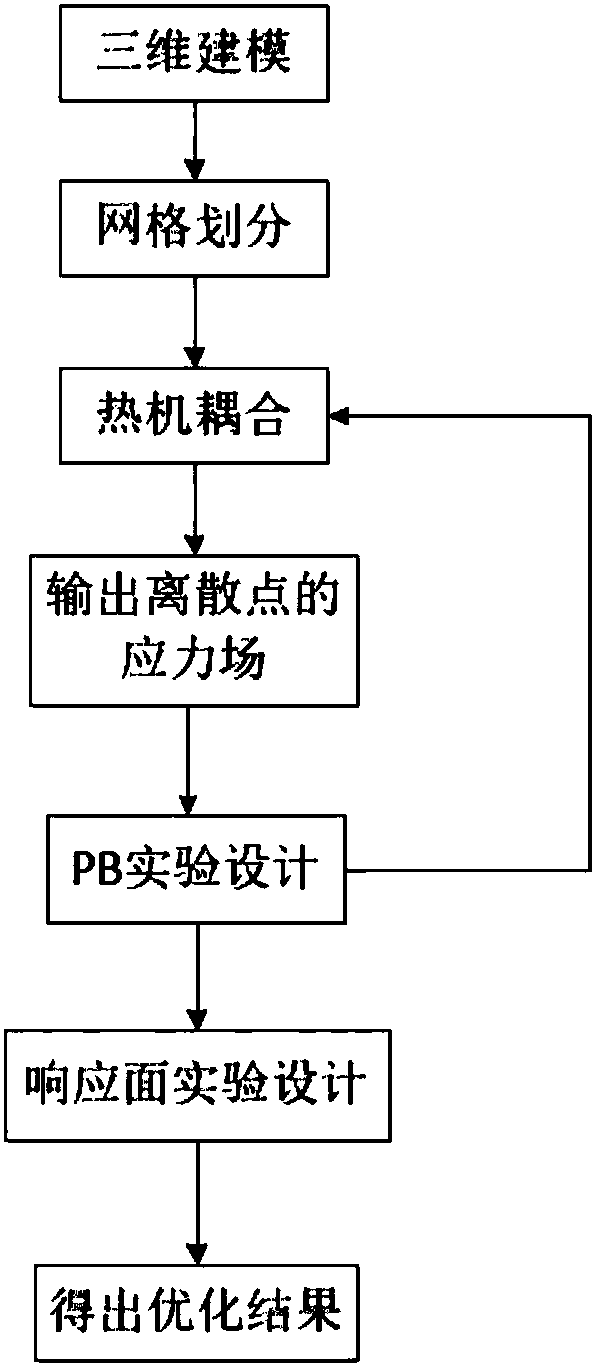

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

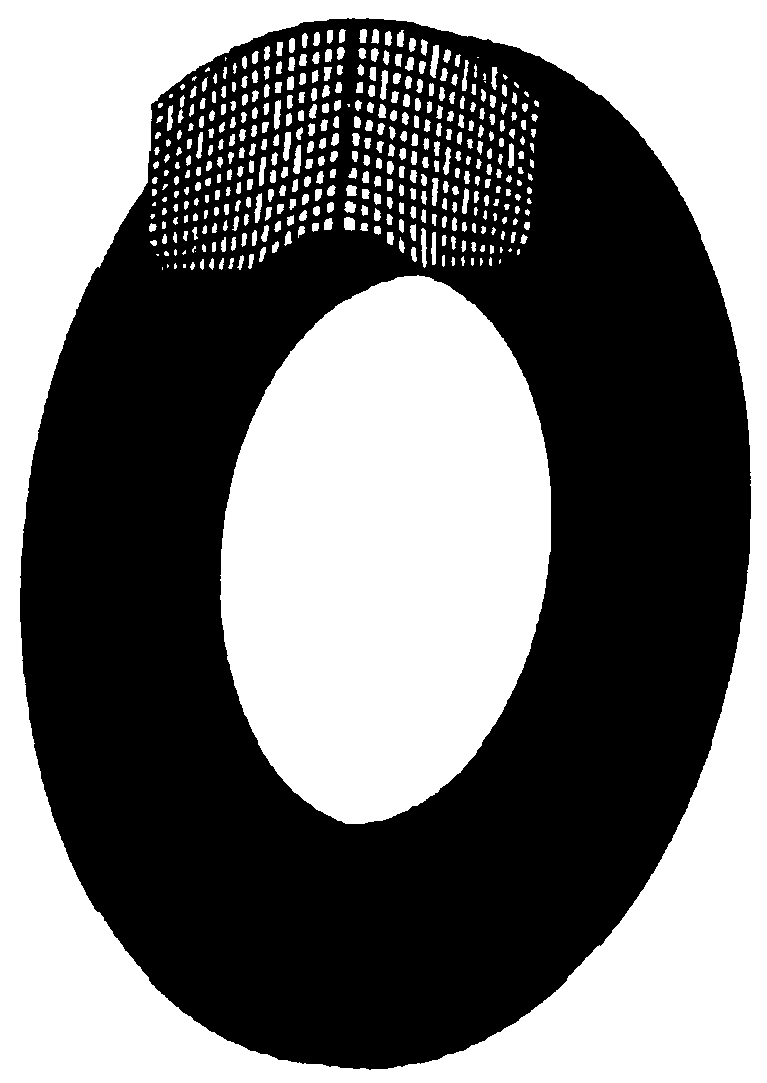

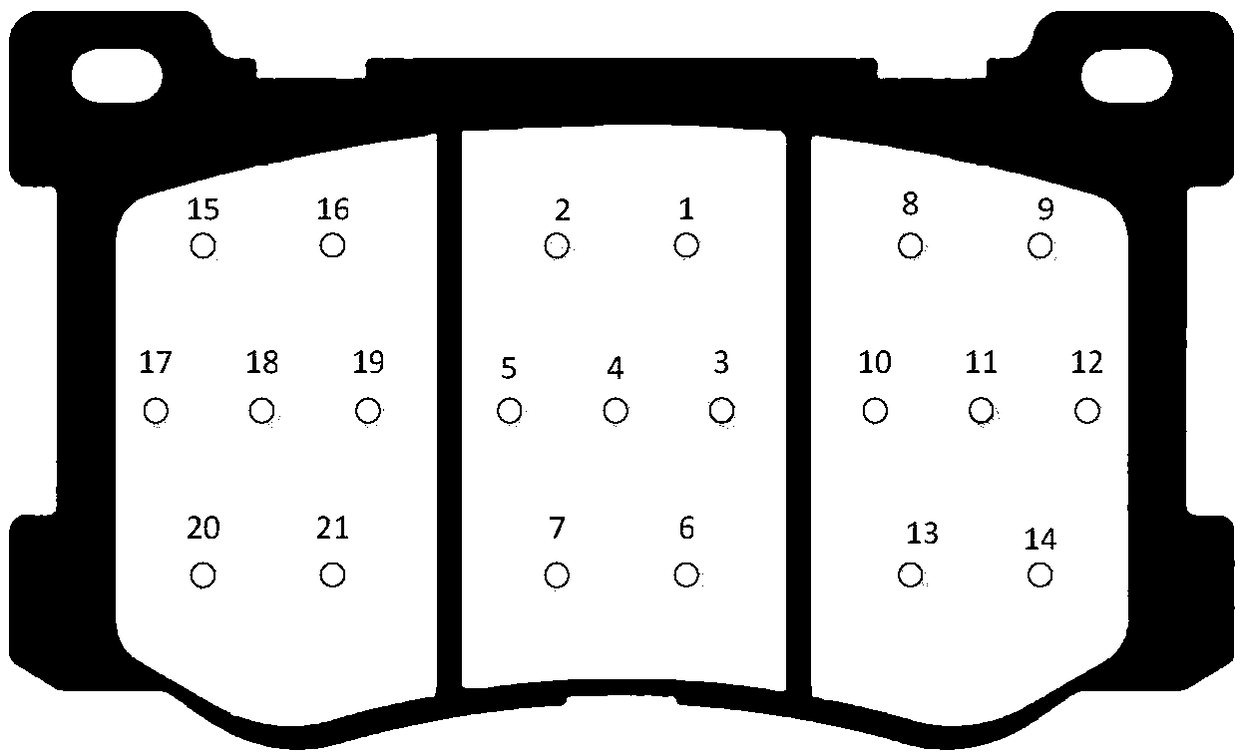

[0026] Such as figure 1 As shown, the two parts forming the contact pair in the embodiment of the present invention include a friction plate and an annular brake disc. The friction plate presses the brake disc at a given contact pressure of 1Mpa, and and the brake disc at a constant speed 15r / s rotation, the contact surface of the two parts is directly without lubrication, and the friction coefficient is 0.37. In this embodiment, the friction lining is in contact wear state within one revolution of the brake disc, while the brake disc is in an indirect wear state. Therefore, the amount of friction lining wear during the entire braking process is much greater than that of the brake disc. In this embodiment, only the wear of the friction plate is considered, and the brake disc is treated as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com