Visual pool type boiling and critical heat flux density test system and test method

A technology of critical heat flux and test system, which is applied in the field of visualized pool boiling and critical heat flux test system, can solve the problems that the types of test data are not complete enough, the angle of the test section cannot be adjusted and visualized, and achieve practical guiding value , the effect of a wide range of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

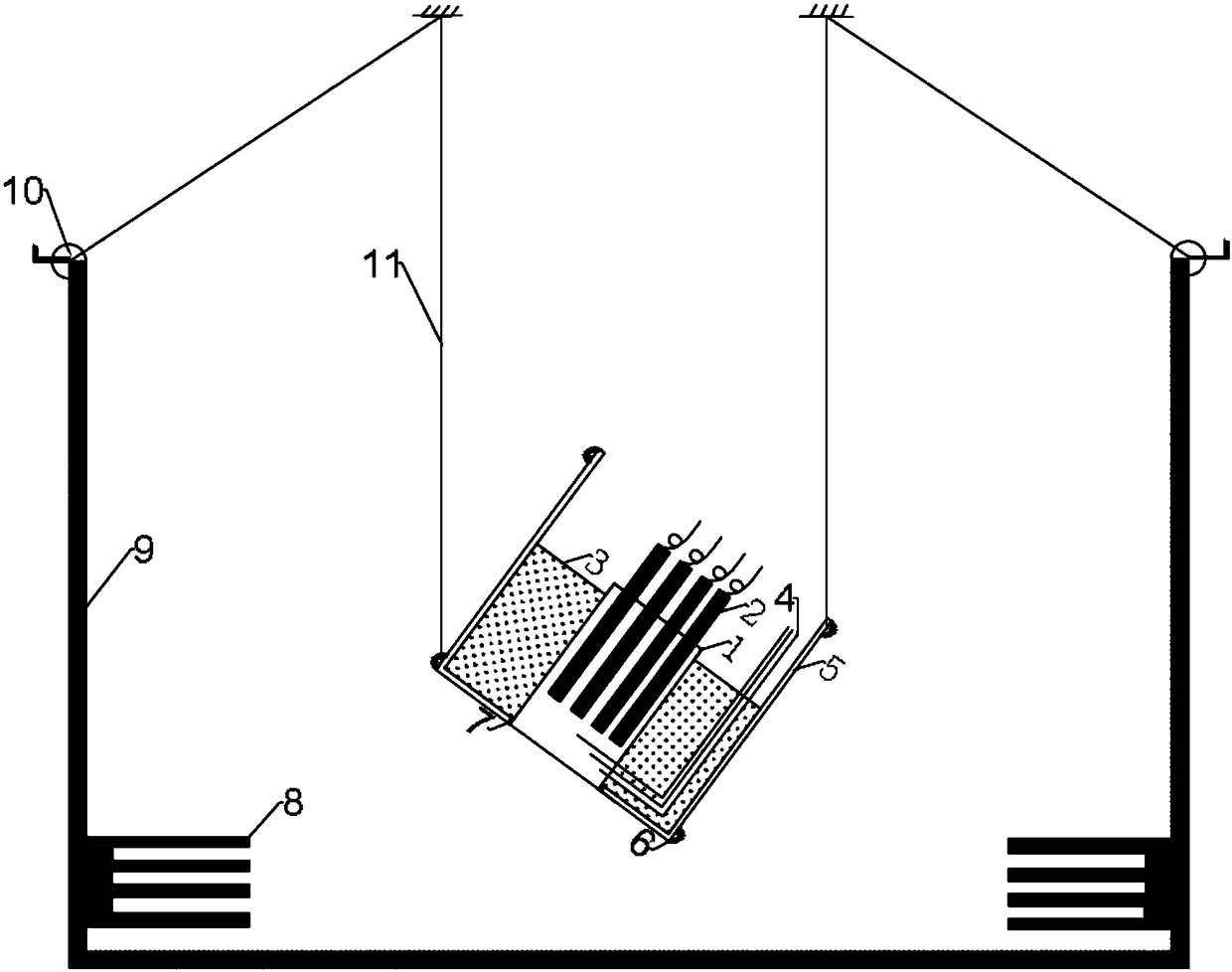

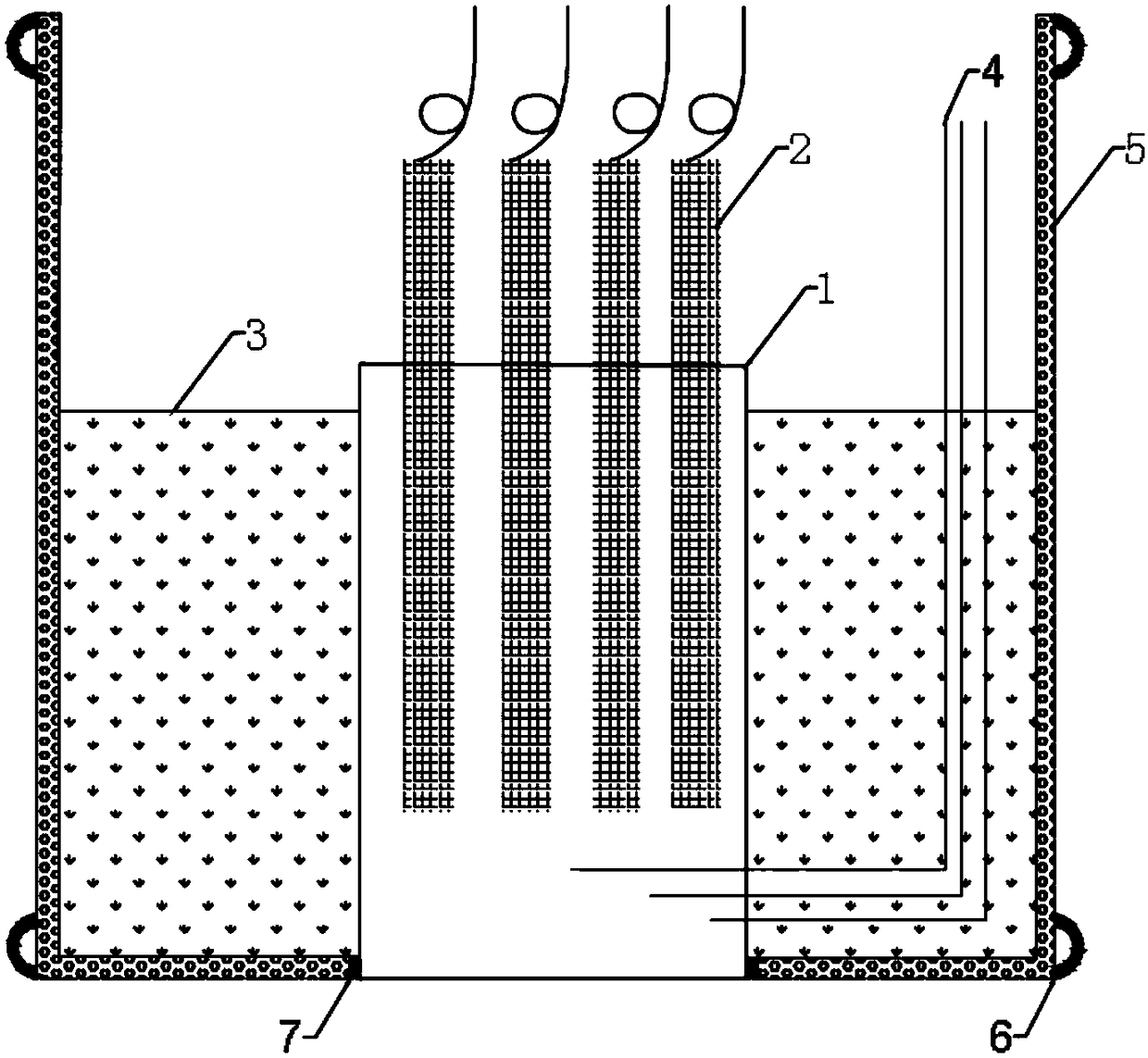

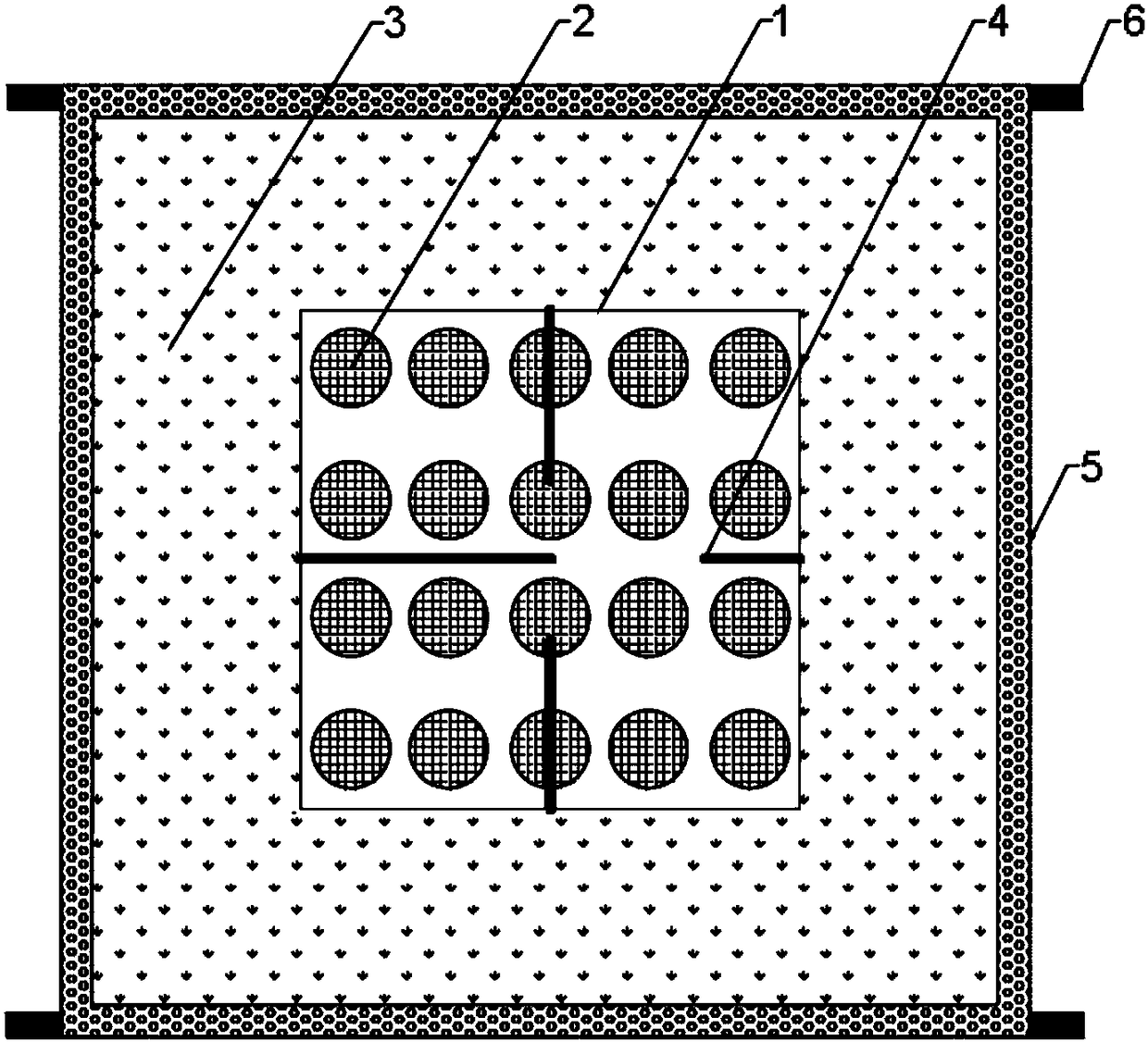

[0024] like figure 1 , Figure 2a and Figure 2b As shown, the present invention is a visual pool type boiling and critical heat flux test system, the test system includes a winch 10, a water tank electric heating rod 8, a transparent water tank 9 and a test section; the test section includes a stainless steel waterproof cover 5, a suspension ring 6 , red copper block 1, electric heating rod 2 in the test section, insulation cotton 3, K-type thermocouple 4; the test section has several types with different heat transfer areas, which are 2cm×2cm, 4cm×4cm, 8cm×8cm, 16cm×16cm , can be conveniently replaced according to different experimental requirements. During the test, the heat exchange surface of the test section, that is, the bottom wall of the copper block 1, is completely immersed in the heat exchange medium of the PC water tank to realize the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com