Photovoltaic module mounting rack well adaptable to environment temperature change

A technology that adapts to the environment and temperature changes. It is applied in the direction of photovoltaic modules, photovoltaic power generation, and support structures of photovoltaic modules. It can solve problems such as poor structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

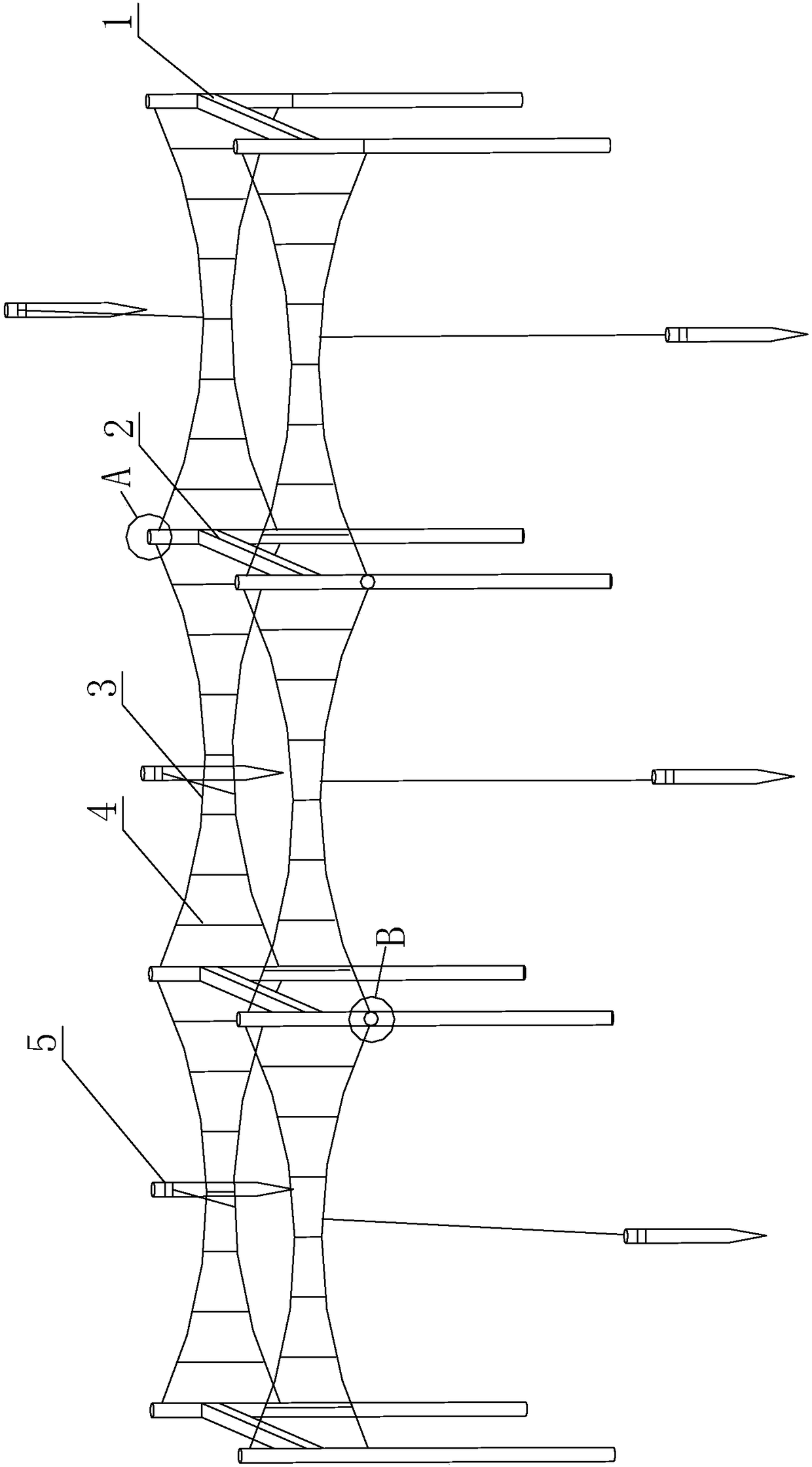

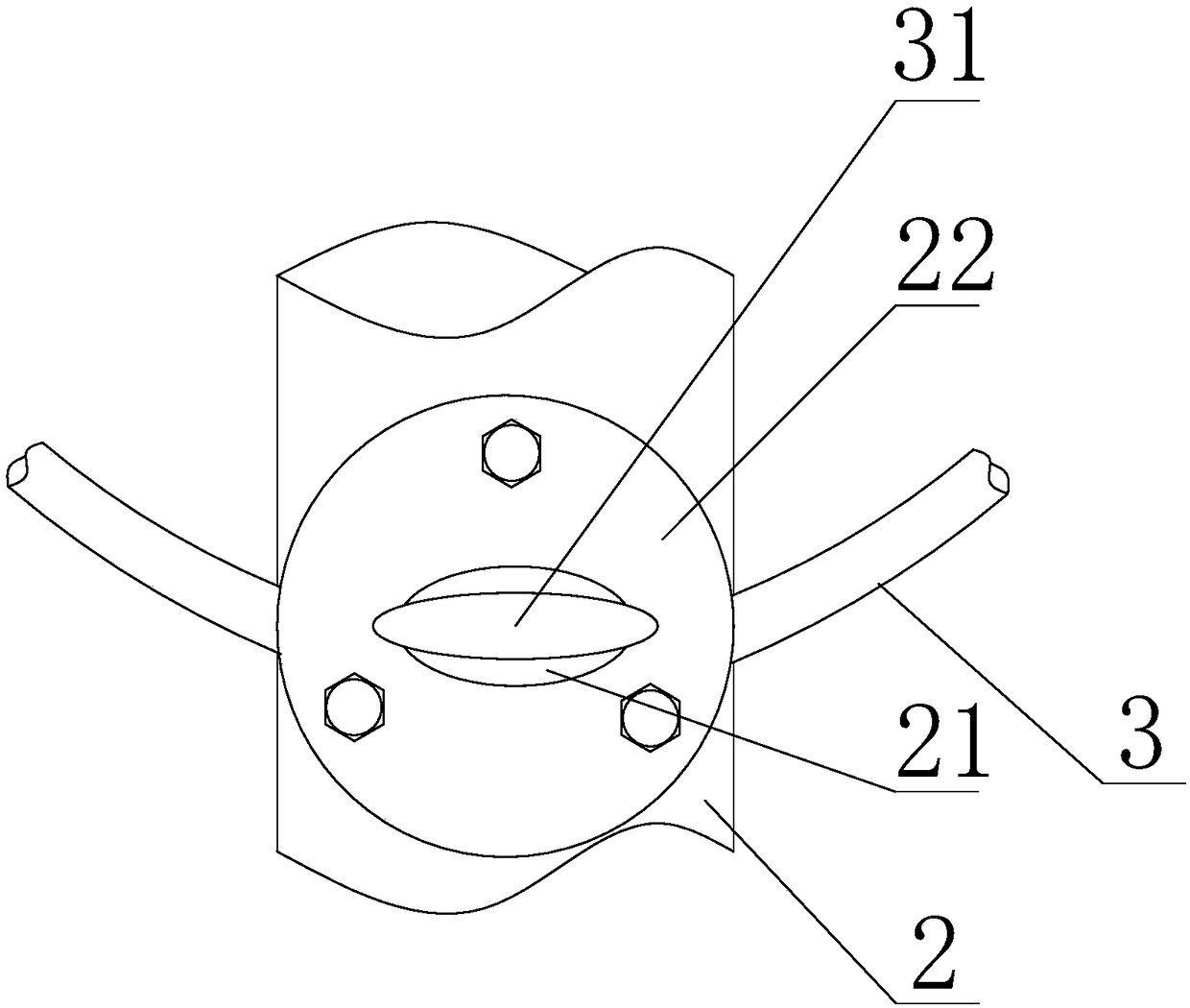

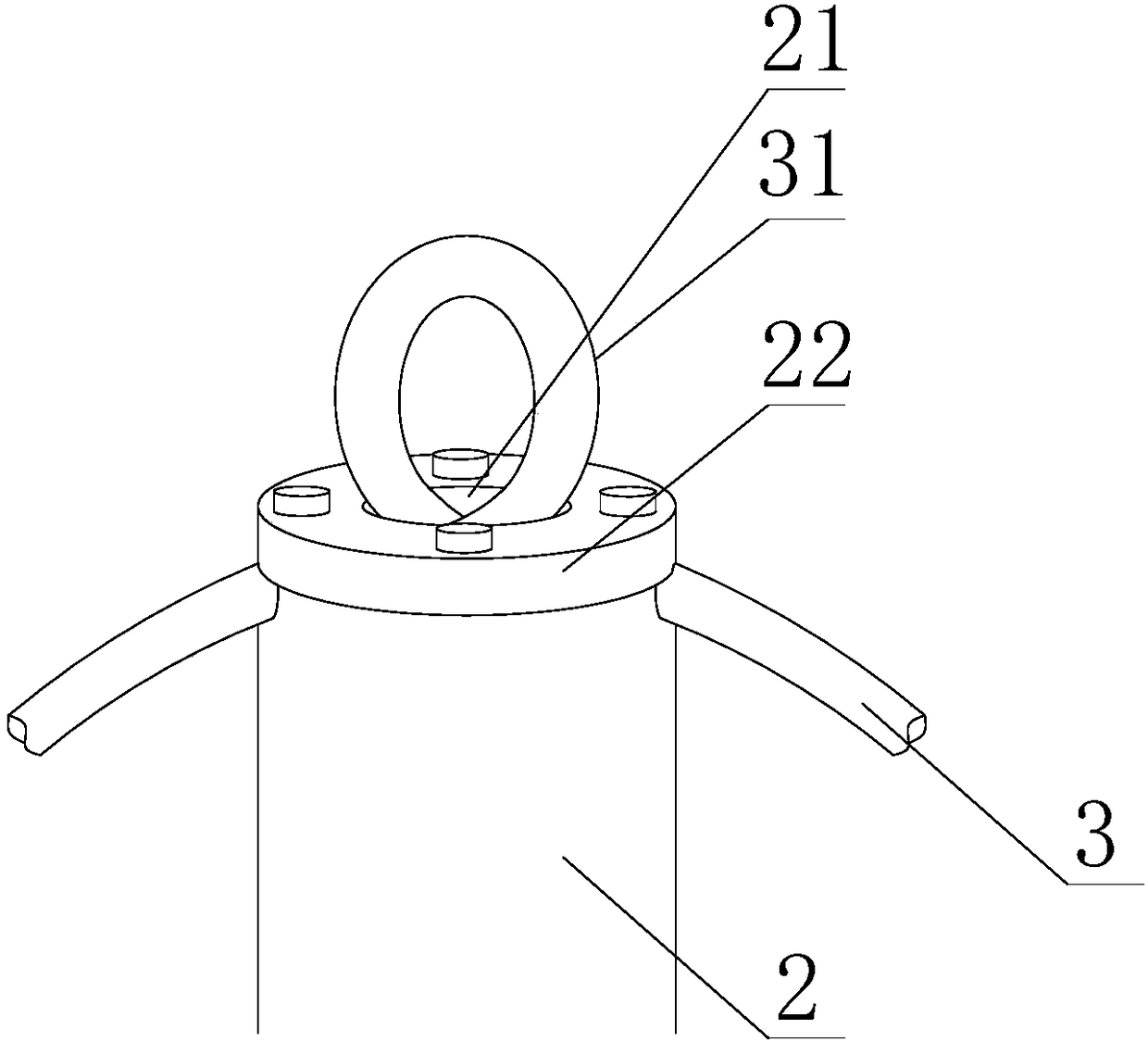

[0049] Such as Figure 1 to Figure 6 As shown in , the photovoltaic module mounting frame that can well adapt to changes in ambient temperature includes multiple poles and multiple cables connected between the poles, and the multiple cables form multiple sets of cable parts;

[0050] Each cable part includes two transverse stay cables 3, and the two transverse stay cables 3 on each cable part are located at different heights;

[0051] Each cable part also includes a plurality of intermediate connectors 4, each intermediate connector 4 is a rod-shaped structure with adjustable length, and the upper end of each intermediate connector 4 is fixed to the upper transverse cable 3 in the cable part. connected, the lower end of each intermediate connector 4 is fixedly connected to the lower transverse stay cable 3 in the stay cable portion;

[0052] Each intermediate connecting member 4 applies a pushing or pulling force to the transverse stay cable 3 connected to its end, so that th...

Embodiment 2

[0062] Such as Figure 1 to Figure 6 As shown, this embodiment is further limited on the basis of Embodiment 1: each upper end cable is located at a different height, and along the distance direction of the adjacent upper end cable, the height of the upper end cable in space increases or decreases successively . In this scheme, if there are N cable parts on the installation frame, then the installation frame includes N upper cable cables parallel to each other, the N upper cable cables are arranged in parallel in space, and the N upper cable cables are at different heights and Arranged in steps. By adopting this scheme, it is convenient for the photovoltaic device to obtain an inclined installation surface to meet the requirement of inclined installation of the photovoltaic device.

[0063] The number of the uprights is three or greater, and a plurality of uprights are arranged in rows or columns, and the uprights at the end of the installation frame are side uprights 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com